Directory

Chapter 1 Introduction

1.1 Definition and Overview of Pure Tungsten Electrode

1.2 The Importance of Pure Tungsten Electrode in the Welding Industry

1.3 Background of Pure Tungsten Electrode Research and Application

Chapter 2 Characteristics of Pure Tungsten Electrode

2.1 Physical Properties of Pure Tungsten Electrode

2.1.1 Melting and Boiling Points of Pure Tungsten Electrode

2.1.2 Density of Pure Tungsten Electrode

2.1.3 Thermal and Electrical Conductivity of Pure Tungsten Electrode

2.1.4 Coefficient of Thermal Expansion of Pure Tungsten Electrode

2.1.5 Vapor Pressure of Pure Tungsten Electrode

2.2 Chemical Properties of Pure Tungsten Electrode

2.2.1 Chemical Stability of Pure Tungsten Electrode

2.2.2 Oxidation Resistance of Pure Tungsten Electrode

2.2.3 Reactivity of Pure Tungsten Electrode with Other Elements

2.3 Electrical Characteristics of Pure Tungsten Electrode

2.3.1 Electron Work of Pure Tungsten Electrode

2.3.2 Arc Stability of Pure Tungsten Electrode

2.3.3 Electrode Consumption Rate of Pure Tungsten Electrode

2.4 Mechanical Properties of Pure Tungsten Electrode

2.4.1 Hardness and Brittleness of Pure Tungsten Electrode

2.4.2 Ductility of Pure Tungsten Electrode

2.4.3 High Temperature Strength and Creep Resistance of Pure Tungsten Electrode

2.5 Comparison of Pure Tungsten Electrode with Other Tungsten Electrode

2.5.1 Pure Tungsten Electrode and Cerium Tungsten Electrode

2.5.2 Pure Tungsten Electrode and Lanthanum Tungsten Electrode

2.5.3 Pure Tungsten Electrode and Thoriated Tungsten Electrode

2.5.4 Pure Tungsten Electrode and Yttrium Tungsten Electrode

2.5.5 Pure Tungsten Electrode and Zirconium Tungsten Electrode

2.6 Pure Tungsten Electrode MSDS from CTIA GROUP LTD

Chapter 3 Preparation and Production Technology of Pure Tungsten Electrode

3.1 Preparation of Raw Materials for Pure Tungsten Electrode

3.1.1 Extraction and Purification of Tungsten Ore

3.1.2 Preparation of High-Purity Tungsten Powder

3.2 Powder Metallurgy Process of Pure Tungsten Electrode

3.2.1 Tungsten Powder Pressing Molding

3.2.2 Sintering Process

3.2.3 Heat Treatment and Annealing

3.3 Pressure Processing of Pure Tungsten Electrode

3.3.1 Forging and Rolling

3.3.2 Drawing and Drawing

3.3.3 Electrode Bar Forming

3.4 Surface Treatment of Pure Tungsten Electrode

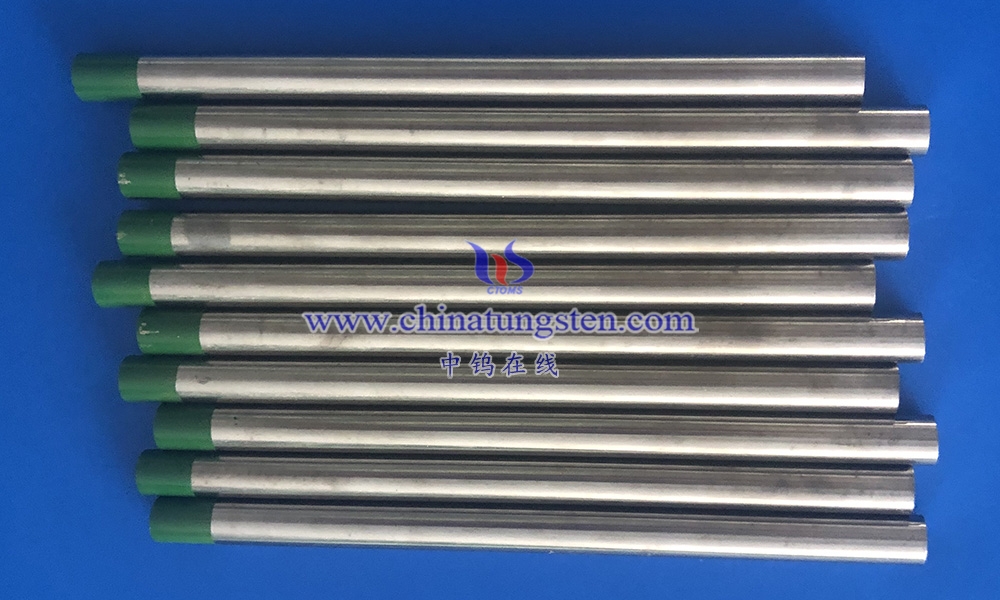

3.4.1 Cleaning and Polishing

3.4.2 Green Smear Markings

3.5 Quality Control of Pure Tungsten Electrode

3.5.1 Raw Material Quality Inspection

3.5.2 Production Process Monitoring

3.5.3 Finished Product Inspection

3.6 Technical Difficulties and Innovations of Pure Tungsten Electrode

3.6.1 High Purity Control

3.6.2 Optimization of Grain Structure

3.6.3 Improvement of Production Efficiency

3.6.4 Environmental Protection and Sustainable Development

Chapter 4 Uses of Pure Tungsten Electrode

4.1 Welding Applications

4.1.1 Tungsten Inert Gas Welding (TIG)

4.1.2 Applications in AC Welding (AC)

4.1.3 Welding of Magnesium, Aluminum and Their Alloys

4.2 Other Industrial Applications

4.2.1 Resistance Welding Electrodes

4.2.2 Plasma Cutting and Spraying

4.2.3 Thermoelectron Emitting Materials

4.2.4 Sputtering Targets

4.2.5 Counterweights and Heating Elements

4.3 Special Field Applications

4.3.1 Aerospace Industry

4.3.2 Military Industry

4.3.3 Nuclear Industry

4.4 Application Limitations

4.4.1 Deficiencies in DC Welding (DC)

4.4.2 Electrode Wear and Life Problems

Chapter 5 Production Equipment for Pure Tungsten Electrode

5.1 Raw Material Processing Equipment for Pure Tungsten Electrode

5.1.1 Tungsten Ore Crushing and Grinding Equipment

5.1.2 Chemical Purification Equipment

5.2 Powder Metallurgy Equipment for Pure Tungsten Electrode

5.2.1 Presses

5.2.2 Sintering Furnaces

5.2.3 Vacuum Heat Treatment Furnaces

5.3 Pressure Processing Equipment for Pure Tungsten Electrode

5.3.1 Forging Machines

5.3.2 Rolling Mills

5.3.3 Wire Drawing Machines

5.4 Surface Treatment Equipment for Pure Tungsten Electrode

5.4.1 Cleaning Equipment

5.4.2 Polishing Machines

5.4.3 Applicator Equipment

5.5 Testing and Quality Control Equipment for Pure Tungsten Electrode

5.5.1 Chemical Composition Analyzers

5.5.2 Microstructure Analysis Equipment

5.5.3 Physical Performance Test Equipment

5.6 Automation and Intelligent Equipment for Pure Tungsten Electrode

5.6.1 Application of Automated Production Lines

5.6.2 Intelligent Monitoring System

Chapter 6 Domestic and Foreign Standards for Pure Tungsten Electrode

6.1 International Standards for Pure Tungsten Electrode

6.1.1 AWS A5.12 (American Welding Institute Standard)

6.1.2 ISO 6848 (International Organization for Standardization)

6.1.3 EN 26848 (European Standard)

6.2 Chinese National Standard for Pure Tungsten Electrode

6.2.1 GB/T 4190 (Tungsten Electrode Standard)

6.2.2 Relevant Industry Standards

6.3 Other National Standards for Pure Tungsten Electrode

6.3.1 JIS Z 3233 (Japanese Industrial Standard)

6.3.2 DIN EN ISO 6848 (German Standard)

6.4 Standard Comparison and Differences of Pure Tungsten Electrode

6.4.1 Chemical Composition Requirements

6.4.2 Dimensions and Tolerances

6.4.3 Performance Test Methods

6.5 The Development Trend of Pure Tungsten Electrode Standards

6.5.1 Environmental and Safety Requirements

6.5.2 High Performance Electrode Standards

Chapter 7 Detection Methods and Technologies of Pure Tungsten Electrode

7.1 Chemical Composition Detection of Pure Tungsten Electrode

7.1.1 Spectroscopic Analysis (ICP-OES)

7.1.2 X-ray Fluorescence Analysis (XRF)

7.1.3 Chemical Titration

7.2 Physical Properties of Pure Tungsten Electrode

7.2.1 Density Measurement

7.2.2 Hardness Testing

7.2.3 Conductivity Test

7.3 Microstructure Analysis of Pure Tungsten Electrode

7.3.1 Light Microscopy Observation

7.3.2 Scanning Electron Microscopy (SEM)

7.3.3 Grain Size Analysis

7.4 Welding Performance Test of Pure Tungsten Electrode

7.4.1 Arc Performance Test

7.4.2 Arc Stability Test

7.4.3 Electrode Consumption Rate Test

7.5 Environmental and Safety Testing of Pure Tungsten Electrode

7.5.1 Radioactivity Detection (Comparison of Thorium-Tungsten Electrodes)

7.5.2 Dust and Exhaust Emission Detection

7.6 Calibration and Standardization of Pure Tungsten Electrode Testing Equipment

7.6.1 Equipment Calibration Methods

7.6.2 International Testing Standards

Chapter 8 Analysis of the Advantages and Disadvantages of Pure Tungsten Electrode

8.1 Advantages of Pure Tungsten Electrode

8.1.1 Low Cost

8.1.2 High Temperature Stability

8.1.3 Suitable for AC Welding

8.2 Disadvantages of Pure Tungsten Electrode

8.2.1 Poor DC Welding Performance

8.2.2 High Electrode Consumption Rate

8.2.3 Difficulty in Arcing and Unstable Arc

8.3 Improvement Direction of Pure Tungsten Electrode

8.3.1 Process Optimization

8.3.2 Alloying Studies

8.3.3 Development of New Electrode Materials

Chapter 9 Market and Development Trend of Pure Tungsten Electrode

9.1 Overview of the Global Tungsten Electrode Market

9.1.1 Major Producing Countries

9.1.2 Market Size and Demand

9.2 China Tungsten Electrode Market Analysis

9.2.1 Domestic Production Capacity

9.2.2 Market Demand and Application Fields

9.3 Development Trend of Pure Tungsten Electrode Technology

9.3.1 Efficient Production Technology

9.3.2 Environmentally Friendly Production Process

9.3.3 Research and Development of New Tungsten Electrode

9.4 Challenges of Pure Tungsten Electrode

9.4.1 Fluctuations in the Price of Raw Materials

9.4.2 Environmental Regulatory Pressure

9.4.3 International Competition

Chapter 10 Conclusions

10.1 Comprehensive Evaluation of Pure Tungsten Electrode

10.2 Future Development Prospect of Pure Tungsten Electrode

10.3 Research and Application Suggestions of Pure Tungsten Electrode

Appendix

- Glossary

- References

Chapter 1 Introduction

1.1 Definition and overview of pure tungsten electrode

Pure tungsten electrode (WP electrode) is a welding electrode material made of high-purity tungsten (tungsten content ≥99.5%) as the main raw material, usually doped with rare earth oxides or other alloying elements, produced by advanced powder metallurgy process, and its surface is coated with green marks to meet the international standard identification specifications. As a rare metal, tungsten has an extremely high melting point (3422°C), high density (19.3 g/cm³), excellent electrical conductivity (about 30% IACS), thermal conductivity (173 W/m·K) and excellent chemical stability, making pure tungsten electrode one of the earliest electrode types used in tungsten argon arc welding (TIG welding). Its high electron work (about 4.52 eV) gives it good thermal electron emission ability at high temperatures, but its application is limited due to the difficulty of arc initiation and insufficient arc stability in DC welding (DC), and it is mainly used for AC welding (AC), especially for the welding of aluminum, magnesium and their alloys.

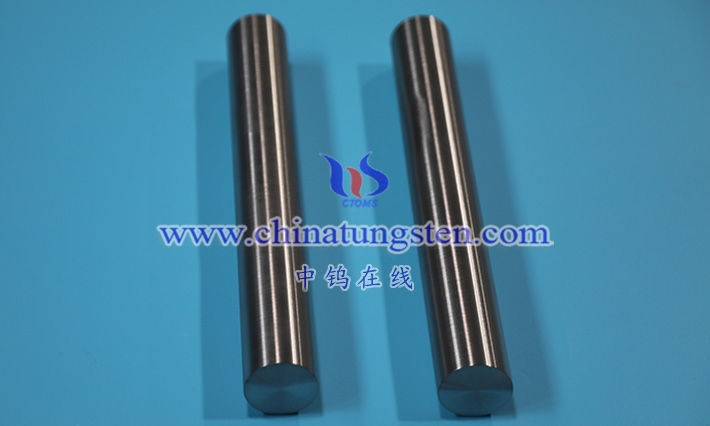

The preparation process of pure tungsten electrodes is complex and precise, involving multiple steps from tungsten ore purification to finished electrodes. First, high-purity tungsten powder is chemically extracted from tungsten ore (such as wolframite or scheelite), and then electrode bars are made by pressing and forming, sintering, forging, wire drawing and surface polishing. Finished electrodes are available in a variety of sizes, typically ranging from 0.5 to 6.4 mm in diameter and 75 to 600 mm in length, with common sizes including 1.0, 1.6, 2.4, 3.2, and 4.0 mm to meet different welding equipment and process needs. In addition, the surface quality and dimensional tolerance of pure tungsten electrodes are critical to welding performance, so the impurity content and grain structure need to be strictly controlled during the production process to ensure the stability and durability of the electrode in high-temperature arc environments.

1.2 The importance of pure tungsten electrode in the welding industry

Pure tungsten electrode has an irreplaceable position in the welding industry, especially in tungsten argon arc welding (TIG welding), because of its unique physical and chemical properties, it has become the preferred material for AC welding. First of all, the high melting point and excellent high-temperature stability of pure tungsten electrodes enable them to maintain structural integrity in high-current (typically 100-300 A) and high-temperature arc (about 6000-7000°C) environments, significantly reducing electrode consumption and extending service life, thereby improving welding efficiency and quality. Secondly, in AC welding, pure tungsten electrode can form a stable hemispherical electrode, which helps to evenly distribute arc energy, effectively remove the oxide film on the surface of light metals such as aluminum and magnesium and their alloys, and form a smooth and dense weld to meet the needs of high-precision welding.

Compared with tungsten electrodes doped with rare earth oxides (such as cerium tungsten electrode, lanthanum tungsten electrode or thorium tungsten electrode), pure tungsten electrode has significant cost advantages and environmentally friendly characteristics. Since it does not contain radioactive elements (e.g. thorium), pure tungsten electrodes have no radiation risk during use and disposal, and meet the requirements of modern green manufacturing and environmental protection regulations. This feature makes it highly desirable in industries with high safety requirements, such as aerospace and medical device manufacturing. In addition, the production process of pure tungsten electrode is mature, the raw material sources are wide, and the price is relatively stable, making it economical in large-scale industrial production.

The application fields of pure tungsten electrodes cover many high-end manufacturing industries. In the automotive industry, pure tungsten electrodes are used to weld aluminum bodies and parts; In the aerospace field, it is used for precision welding of titanium alloys and aluminum alloys; In the electrical and electronics industry, it is used for welding thin-walled metals and miniature components. Thanks to the transformation and upgrading of the global manufacturing industry and the growing demand for high-quality welding processes, the market demand for pure tungsten electrodes continues to expand. Although some of its limitations in DC welding have led to the replacement of doped electrodes in some applications, pure tungsten electrodes remain indispensable in AC welding, resistance welding, and some plasma cutting and spraying processes.

1.3 Background of pure tungsten electrode research and application

As a strategic rare metal, tungsten has been widely used in industrial and military fields since the end of the 19th century due to its excellent physical and chemical properties. The R&D and application of pure tungsten electrode began in the early 20th century, which is closely related to the birth and development of tungsten argon arc welding technology. In the 1910s, tungsten electrodes were first used in welding experiments, and their high melting point and thermal electron emission capabilities quickly made them the core material for TIG welding. However, due to the high electron escape work in the early pure tungsten electrode, there are problems of arc initiation and arc instability in DC welding, which limits its application range. To overcome these shortcomings, researchers have been exploring tungsten electrodes doped with rare earth oxides (e.g., cerium oxide, lanthanum oxide, thorium oxide) since the mid-20th century to reduce electron work and improve arc initiation performance and arc stability. Although doped electrodes perform well in DC welding, pure tungsten electrodes retain an important market position due to their non-radioactivity, low cost, and suitability for AC welding.

In the late 20th century, with the rapid development of aerospace, automobile manufacturing, nuclear industry and electronic and electrical industries, the demand for high-performance welding materials increased significantly, which promoted the continuous improvement of pure tungsten electrode production process. Modern production technologies include high-purity tungsten powder preparation, isostatic press forming, vacuum sintering, precision forging and automated wire drawing, etc., which significantly improve the purity, grain uniformity and mechanical properties of the electrode. In addition, international standards (e.g., AWS A5.12, ISO 6848) and Chinese national standards (e.g., GB/T 4190) specify the chemical composition, dimensional tolerance, surface quality and performance test methods of pure tungsten electrodes, which promotes their standardized production and application in the global market.

As the country with the world’s largest tungsten resource reserves (about 1.9 million tons, accounting for more than 50% of the world’s total) and production (about 80% of the world’s in 2024), China has a complete industrial chain from tungsten mining, smelting to electrode manufacturing. Through technological innovation and large-scale production, domestic enterprises have significantly improved the international competitiveness of pure tungsten electrodes. At the same time, industry information platforms such as Chinatungsten Online Technology Co., Ltd. publish market trends, technical progress and price information through the website and WeChat official account, providing customized solutions for global customers and becoming an authoritative source of information in the tungsten products industry.

At present, the research directions of pure tungsten electrodes include optimizing grain structure to improve wear resistance and arc stability, developing efficient and environmentally friendly production processes to reduce energy consumption and emissions, and exploring new electrode materials to meet diverse welding needs. In addition, the global emphasis on green manufacturing and sustainable development has promoted the development and application of non-radioactive electrodes, and pure tungsten electrodes have an advantage in this trend due to their environmentally friendly characteristics. In the future, with the further development of new energy, aerospace and high-end equipment manufacturing, the application prospect of pure tungsten electrode will be broader.

READ MORE: Encyclopedia of Pure Tungsten Electrode

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

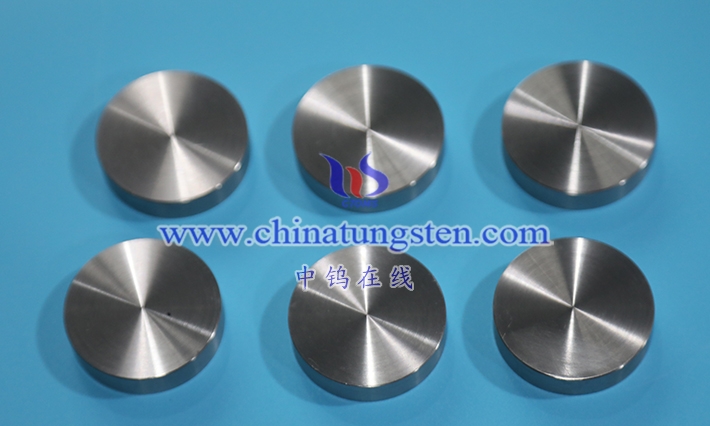

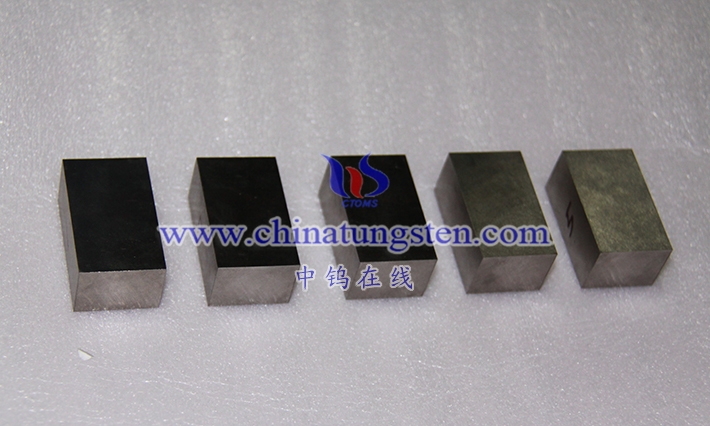

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten alloy products, please visit the website: http://tungsten.com.cn/EB-tungsten-filament.html

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595