Directory

Chapter 1 Introduction

1.1 Definition and Overview of Tungsten Rods

1.2 The Importance of Tungsten Rods in Industry

1.3 Historical Background and Development

Chapter 2 Types of Tungsten Rods

2.1 Tungsten Rods Are Classified by Composition

2.1.1 Pure Tungsten Rods

2.1.2 High Purity Tungsten Rods (≥99.95%)

2.1.3 Doped Tungsten Rods (Rare Earth Doping, Oxide Doping)

2.2 Tungsten Rods Are Classified According to the Manufacturing Process

2.2.1 Sintered Tungsten Rods

2.2.2 Forged Tungsten Rods

2.2.3 Rolled Tungsten Rods

2.2.4 Draw Tungsten Rods

2.2.5 Extrude Tungsten Rods

2.3 Tungsten Rods Are Classified According to Their Use

2.3.1 Tungsten Rods for Industrial Use

2.3.2 Tungsten Rods for Electronics

2.3.3 Tungsten Rods for Military Use

2.3.4 Other Special Purpose Tungsten Rods

2.4 Tungsten Rods Are Classified According to Specifications

2.4.1 Small Diameter Tungsten Rods (<5mm)

2.4.2 Medium Diameter Tungsten Rods (5–20mm)

2.4.3 Large Diameter Tungsten Rods (>20mm)

2.5 Tungsten Rods Are Classified According to Their Surface State

2.5.1 Black Leather Sticks

2.5.2 Cartlight Sticks

2.5.3 Polishing Rods

2.6 Special Tungsten Rods

2.6.1 Potassium Tungsten Rods

2.6.2 Thorium-Doped Tungsten Rods

2.6.3 Cerium-Doped Tungsten Rods

2.6.4 Lanthanum-Doped Tungsten Rods

2.6.5 Zirconium-Doped Tungsten Rods

2.6.6 Yttrium-Doped Tungsten Rods

2.6.7 Composite Rare Earth Tungsten Rods

2.7 Comparison of International Models and Grades

2.7.1 Pure Tungsten Rod Grades

2.7.2 Doped Tungsten Rod Grades

2.7.4 Domestic and Foreign Grades (GB/T, ASTM, ISO)

Chapter 3 Characteristics of Tungsten Rods

3.1 Physical Properties of Tungsten Rods

3.1.1 High Melting Point of Tungsten Rods

3.1.2 High Density of Tungsten Rods

3.1.3 Low Coefficient of Thermal Expansion of Tungsten Rods

3.1.4 Thermal and Electrical Conductivity of Tungsten Rods

3.1.5 Low Vapor Pressure of Tungsten Rods

3.2 Chemical Properties of Tungsten Rods

3.2.1 Corrosion Resistance of Tungsten Rods

3.2.2 Chemical Stability of Tungsten Rods

3.2.3 Reactivity of Tungsten Rods with Other Elements

3.3 Mechanical Properties of Tungsten Rods

3.3.1 High Strength and Hardness of Tungsten Rods

3.3.2 Creep Resistance of Tungsten Rods

3.3.3 Toughness and Machinability of Tungsten Rods

3.4 Comparison of Characteristics of Different Types of Tungsten Rods

3.4.1 Pure Tungsten Rods and High Purity Tungsten Rods

3.4.2 Special Properties of Doped Tungsten Rods

3.5 Tungsten Rods MSDS from CTIA GROUP LTD

Chapter 4 Preparation and Production Technology of Tungsten Rods

4.1 Preparation of Raw Materials for Tungsten Rods

4.1.1 Mining and Purification of Tungsten Ore

4.1.2 Preparation of Tungsten Powder

4.1.3 Addition of Alloying Elements and Dopants

4.2 Powder Metallurgy Technology of Tungsten Rods

4.2.1 Powder Mixing and Pressing

4.2.2 High Temperature Sintering

4.2.3 Performance Optimization of Sintered Tungsten Rods

4.3 Tungsten Rod Deformation Processing Technology

4.3.1 Hot Forging (Hammer Forging, Rotary Forging)

4.3.2 Hot Extrusion

4.3.3 Rolling

4.3.4 Pulling

4.4 Preparation of Large-Scale Tungsten Rods

4.4.1 Technical Difficulties and Challenges

4.4.2 Preparation Method of High-Density Tungsten Rods

4.4.3 Process Optimization and Innovation

4.5 Post-Treatment Technology of Tungsten Rods

4.5.1 Heat Treatment

4.5.2 Surface Treatment (Polishing, Cleaning)

4.5.3 Precision Machining and Cutting

4.6 Process Characteristics of Different Types of Tungsten Rods

4.6.1 Pure Tungsten Rod Process

4.6.2 High-Purity Tungsten Rod Process

4.6.3 Doped Tungsten Rod Process

Chapter 5 Uses of Tungsten Rods

5.1 Industrial Applications of Tungsten Rods

5.1.1 Tungsten Core Rods for Quartz Furnace

5.1.2 Preparation of Monocrystalline Silicon Wafers

5.1.3 Rare Earth Element Purification

5.1.4 Tungsten Crucible for Sapphire Crystal Furnace

5.2 Tungsten Rods Are Used in Military and National Defense

5.2.1 Armor-Piercing Cores

5.2.2 High-Explosive Tungsten Rods

5.3 Tungsten Rods Are Used in Electronics and Lighting

5.3.1 Tungsten Filament (Filament, Support Wire)

5.3.2 Electrodes (Tungsten Electrodes, Rare Earth Tungsten Electrodes)

5.3.3 Sputtering Targets

5.4 Tungsten Rods Are Used in Automotive and Aerospace

5.4.1 Automotive Automation Components

5.4.2 Aerospace High-Temperature Components

5.5 Tungsten Rods Are Used in Medical and Scientific Research

5.5.1 Medical Devices (Radiation Shielding)

5.5.2 Experimental Equipment (High Temperature Experiments)

5.6 Tungsten Rods Are Used in Other Fields

5.6.1 Sporting Goods (Tungsten Carbide Darts)

5.6.2 Jewellery (Tungsten Carbide Jewellery)

5.6.3 Special Tools and Molds

Chapter 6 Tungsten Rod Production Equipment

6.1 Powder Metallurgy Equipment for Tungsten Rods

6.1.1 Mixers

6.1.2 Presses

6.1.3 High Temperature Sintering Furnace

6.2 Tungsten Rod Deformation Processing Equipment

6.2.1 Air Hammers and Electro-Hydraulic Hammers

6.2.2 Rotary Swaging Machines

6.2.3 Hot Extruders

6.2.4 Rolling Mills and Drawing Machines

6.3 Post-Processing Equipment for Tungsten Rods

6.3.1 Heat Treatment Furnaces

6.3.2 Polishing and Cleaning Equipment

6.3.3 Precision Machining Equipment (Lathes, Grinding Machines)

6.4 Advanced Production Equipment for Tungsten Rods

6.4.1 Plasma Sintering Equipment

6.4.2 Vacuum Melting Furnaces

6.4.3 Automatic Control and Monitoring Systems

6.5 Equipment Selection and Maintenance of Tungsten Rods

6.5.1 Equipment Requirements for Different Types of Tungsten Rods

6.5.2 Equipment Maintenance and Life Management

Chapter 7 Domestic and Foreign Standards for Tungsten Rods

7.1 International Standards for Tungsten Rods

7.1.1 ISO Standard (ISO 24370: Tungsten and Tungsten Alloys)

7.1.2 ASTM Standard (ASTM B777: High Density Tungsten Alloy)

7.1.3 RWMA Class 13

7.1.4 Other International Standards

7.2 Chinese Standard for Tungsten Rods

7.2.1 GB/T 4187-2017 (National Standard for Tungsten Bar)

7.2.2 GB/T 3459-2017 (Tungsten and Tungsten Alloy Products)

7.2.3 Industry Standard (YS/T 695-2009: Tungsten Electrode)

7.3 Standard Comparison and Applicability of Tungsten Rods

7.3.1 Differences Between Domestic and Foreign Standards

7.3.2 Standard Requirements for Different Types of Tungsten Rods

7.3.3 The Guiding Significance of Standards for Production and Testing

Chapter 8 Detection of Tungsten Rods

8.1 Physical Properties of Tungsten Rods Test

8.1.1 Density Test of Tungsten Rods

8.1.2 Hardness Test of Tungsten Rods (Vickers, Brinell)

8.1.3 Tensile Strength and Toughness Test of Tungsten Rods

8.1.4 Thermal Expansion and Thermal Conductivity Test of Tungsten Rods

8.2 Chemical Composition Analysis of Tungsten Rods

8.2.1 Spectroscopic Analysis (ICP-MS, XRF)

8.2.2 Detection of Trace Elements and Impurities

8.3 Microstructure Analysis of Tungsten Rods

8.3.1 Microscope Observation (SEM, TEM)

8.3.2 Grain Size and Microstructure Uniformity

8.4 Non-Destructive Testing of Tungsten Rods

8.4.1 Ultrasonic Testing

8.4.2 X-Ray Inspection

8.4.3 Magnetic Particle Testing

8.5 Performance Verification of Tungsten Rods

8.5.1 High Temperature Performance Test

8.5.2 Corrosion Resistance Test

8.5.3 Conductivity and Creep Test

8.6 Key Points of Detection of Different Types of Tungsten Rods

8.6.1 Pure Tungsten Rods Detection

8.6.2 High-Purity Tungsten Rods Detection

8.6.3 Doped Tungsten Rods Detection

Chapter 9 Tungsten Rod Industry Status and Development Trend

9.1 Overview of Tungsten Rod Market in China

9.1.1 Market Demand and Supply Analysis

9.2 Overview of the International Tungsten Rod Market

9.2.1 Major Exporting Countries and Regions

9.2.2 Import Dependence and Supply Chain Status

9.3 Technology Development Trend of Tungsten Rods

9.3.1 New Materials and Alloying Technologies

9.3.2 Green Manufacturing and Energy-Saving Technologies

9.3.3 Intelligent and Automated Production

9.4 Challenges and Opportunities of Tungsten Rods

9.4.1 Technical Bottlenecks and Breakthroughs

9.4.2 Market Competition and Globalization

9.4.3 Requirements for Environmental Protection and Sustainable Development

Chapter 10 Conclusions

10.1 The Core Value and Application Prospect of Tungsten Rods

10.2 Future Development Direction of Tungsten Rods

10.3 Recommendations for Industry Development

Appendix

A. Glossary

B. References

Chapter 1 Introduction

1.1 Definition and overview of tungsten rods

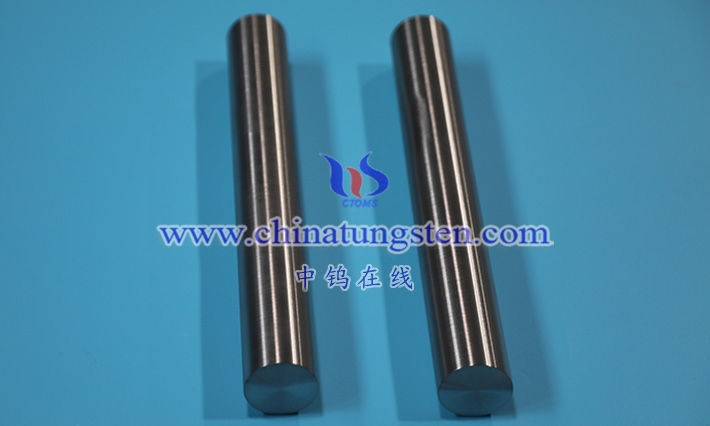

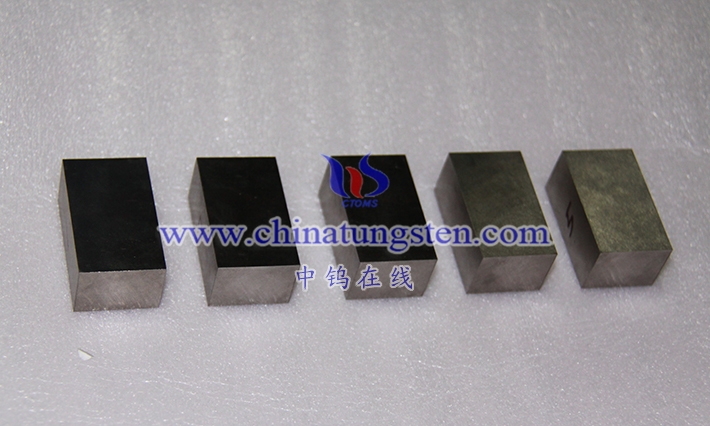

Tungsten rod is a rod-shaped metal material made of tungsten (chemical element symbol W, atomic number 74) or its alloy as the main component, through powder metallurgy, forging, drawing or extrusion processes. Tungsten rods are known for their excellent physical, chemical and mechanical properties, including an extremely high melting point (3410°C), high density (19.25 g/cm³), excellent corrosion resistance and excellent mechanical strength. These properties make tungsten rods indispensable in many demanding industrial sectors such as aerospace, electronics, military, medical, and high-temperature manufacturing.

The basic composition of tungsten rod

Tungsten rods can be divided into three categories according to their composition: pure tungsten rods, high-purity tungsten rods and doped tungsten rods.

Pure tungsten rod: with high-purity tungsten (purity≥99.9%) as the main component, it is suitable for high-temperature, high-strength and corrosion-resistant environments, such as vacuum tube cathodes, X-ray tube targets and high-temperature furnace core rods in the electronics industry.

High Purity Tungsten Rod (≥ 99.95%): Tungsten with a purity of 99.95% or more and a very low impurity content (<50 ppm) is designed for semiconductor, medical and high-end electronic devices that require high cleanliness and precision, such as ion implantation device components and sputtering targets.

Doped tungsten rod (rare earth doping, oxide doping): Rare earth elements (such as cerium, lanthanum, yttrium) or oxides (such as thorium oxide, zirconia) are added to the tungsten matrix to improve arc stability, creep resistance and processing performance, and are widely used in welding electrodes (such as argon arc welding electrodes) and high-temperature furnace elements.

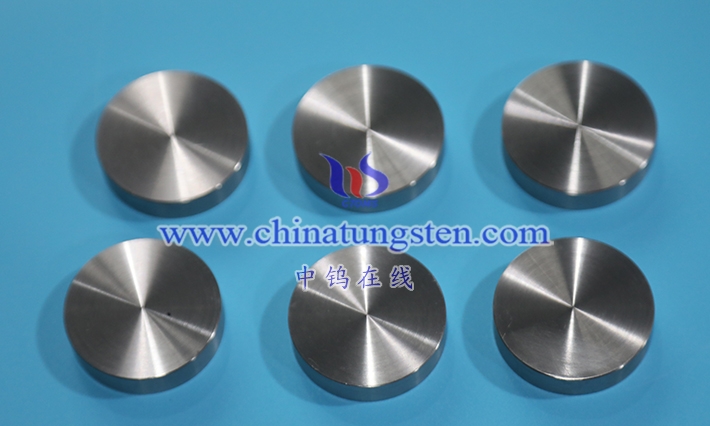

Shape and specification of tungsten rod

Tungsten rods come in a variety of forms, with diameters ranging from microns (e.g., drawn tungsten rods for filaments) to tens of millimeters (e.g., large-scale industrial tungsten rods). Their lengths are often customized to the needs of the application, ranging from a few centimeters to several meters. The surface condition also varies depending on the machining process, including black rods (unfinished with an oxide layer), polishing rods (smooth surface after machining) and polishing rods (with an extremely high surface finish for precision applications).

Preparation process of tungsten rod

Tungsten rods are usually prepared using powder metallurgy technology, and the basic process includes:

Tungsten powder preparation: high-purity tungsten powder is purified from tungsten ore (such as wolframite or scheelite).

Powder pressing and sintering: tungsten powder is pressed into a blank and sintered at high temperature (2000-3000°C) to form a dense sintered tungsten rod.

Deformation processing: further processing by hot forging, rotary swaging, rolling or drawing to improve the density and mechanical properties of the material.

Post-processing: including heat treatment, surface polishing, or cleaning to meet specific application needs.

Unique properties of tungsten rods

Tungsten rods are preferred for their unique combination of properties:

High melting point: Tungsten has the highest melting point of any metal and is suitable for extremely high temperature environments such as quartz furnaces and sapphire crystal furnaces.

High density: The proximity to gold density gives it an advantage in areas that require high-quality counterweights, such as aerospace balances.

Corrosion resistance: Tungsten has excellent corrosion resistance to most acids and bases at room temperature, and will only react slowly in high-temperature and strong oxidizing environments (such as nitric acid).

Mechanical strength: Tungsten rod still maintains high strength and creep resistance at high temperatures, and is suitable for long-term stressed parts.

Electrical and thermal conductivity: Although less conductive than metals such as copper, its stability at high temperatures makes it excellent in electrodes and filaments.

Classification and nomenclature of tungsten rods

Tungsten rods are often named based on their composition, use, or international standards. For example:

International standards: such as ASTM B760 (pure tungsten rod).

Doped tungsten rod grades: such as WT20 (2% thorium-doped tungsten rod), WL15 (1.5% lanthanum-doped tungsten rod), in line with AWS A5.12 standard.

Domestic standards, such as GB/T 4187-2017, specify the chemical composition, dimensional tolerances and performance requirements of tungsten rods. These nomenclature systems facilitate global trade and application, ensuring uniformity and traceability of material specifications.

Global tungsten rod market overview

As a high-performance material, tungsten rod is widely used in global industrial systems. China is the world’s largest tungsten resource and tungsten product producer, accounting for more than 80% of global tungsten production, mainly exported to the United States, Europe and Japan. The production of tungsten rods is concentrated in a small number of specialized enterprises, and the market demand is mainly driven by semiconductor manufacturing, new energy, aerospace and defense industries.

Tungsten rod is environmentally friendly and sustainable

The production of tungsten rods involves tungsten ore mining and high-temperature processing, which is energy-intensive and can produce exhaust gases and residues. In recent years, green manufacturing technologies (e.g. low-energy sintering, waste recycling) have been adopted to reduce environmental impact. In addition, the high durability and recyclability of tungsten rods make them sustainable throughout their life cycle.

1.2 The importance of tungsten rods in industry

Tungsten rods play a key role in global industries due to their excellent performance and are widely used in high-tech, demanding fields such as semiconductor manufacturing, aerospace, defense, energy, medical and lighting industries. Its importance is reflected in its unique properties that meet the material needs of extreme environments, driving technological progress and industrial efficiency. The importance of tungsten rods in industry is discussed in detail from multiple perspectives.

Core applications in high-temperature environments

The high melting point of tungsten rod (3410°C) makes it an irreplaceable material in high-temperature environments. In the quartz continuous melting furnace, the tungsten rod is used as a core rod to withstand extreme temperatures of more than 2000°C for the production of high-purity quartz glass, which is widely used in the optical fiber and semiconductor industries. Similarly, in a sapphire crystal furnace, tungsten rods are processed into crucibles or supports for the production of artificial sapphire crystals, which are used in LED substrates and optical windows. The creep resistance of tungsten rods ensures structural stability even under long-term high temperature stress, which is unmatched by other metal materials such as nickel and molybdenum.

The backbone of the semiconductor and electronics industries

Semiconductor manufacturing requires extremely high material purity and performance, and tungsten rods play an important role in this. For example, in the production of monocrystalline silicon, tungsten rods are used as heating elements or support structures for high-temperature furnaces to ensure the stability and uniformity of crystal growth. In addition, doped tungsten rods (such as cerium-doped or lanthanum-doped tungsten rods) are widely used as argon arc welding electrodes for precision welding of semiconductor equipment, and their excellent arc stability and wear resistance improve welding quality and efficiency. Tungsten rods are also processed into sputtering targets for use in physical vapor deposition (PVD) processes to manufacture thin film layers for integrated circuits and displays.

Strategic materials in the field of defense and military

The high density and hardness of tungsten rods make it a strategic material for the military industry. Tungsten alloy rods (e.g. tungsten nickel-iron alloy, with a density of up to 18.5 g/cm³) are processed into armor-piercing cores for striking anti-tank and armored targets, with high kinetic energy and penetration far exceeding those of conventional steels. In addition, tungsten rods were conceived in the concept of “kinetic weapons” as high-density kinetic warheads, and although they have not yet been actually deployed, their potential shows the importance of tungsten rods in future military technology. The high temperature and corrosion resistance of tungsten rods also make them suitable for missile nozzles and armor parts.

A reliable choice for the aerospace industry

Tungsten rods are widely used in the aerospace industry, where materials are extremely demanding in terms of weight, strength and high temperature resistance. Tungsten alloy rods are used as counterweights for aircraft and satellites due to their high density, ensuring precise weight distribution and flight stability. For example, in helicopter rotors and spacecraft attitude control systems, tungsten rod counterweights significantly reduce volume requirements. In addition, tungsten rods are machined into high-temperature components, such as rocket engine nozzle linings and thermal protection components for re-entry vehicles, whose anti-ablative properties extend component life.

Critical components in the lighting and energy industry

In the lighting industry, tungsten rods are the core material of traditional incandescent and halogen lamps. Tungsten rods are drawn into filaments (which can be as small as a few microns in diameter) and are used as filaments that emit light for long periods of time at high temperatures due to their high melting point and low vapor pressure. Although LED technology is gradually replacing traditional lighting, tungsten filament is still indispensable in specialty lighting such as photographic lights and stage lights. In the field of new energy, tungsten rods are used in the control rods and high-temperature experimental devices of nuclear reactors to ensure safety and experimental accuracy.

A unique contribution to the medical and scientific fields

The high density and radiation shielding ability of tungsten rods make them shine in the medical field. Tungsten alloy rods are processed into collimators and shields for radiotherapy equipment that are used to precisely direct X-rays or gamma rays to protect patients and medical staff from unwanted radiation. In the field of scientific research, tungsten rods are used as heating elements or electrodes in high-temperature experimental furnaces, supporting cutting-edge research in materials science, physics and chemistry. For example, in high-temperature superconductivity experiments, the stability of tungsten rods ensures the reliability of the experimental environment.

Drive industrial efficiency and innovation

The diverse applications of tungsten rods not only meet the existing industrial needs, but also promote technological innovation. For example, in the automotive industry, tungsten rods are used to manufacture wear-resistant tools and molds for automated production lines, improving production efficiency and product consistency. In the sporting goods (e.g., golf clubs, darts) and jewelry industries, tungsten alloy rods are machined into precision components due to their high density and wear resistance to meet consumer demand for high-performance products. These emerging applications demonstrate the wide adaptability of tungsten rods in both traditional and modern industries.

The importance of the economy and the supply chain

As a rare metal product, tungsten rod has an important position in the global economy. China is the world’s largest producer of tungsten, controlling about 80% of the tungsten resources and products market, and the export of tungsten rods is critical to the international supply chain. The high added value and irreplaceability of tungsten rod make it a strategic reserve material for the industrial system of many countries. For example, the United States and the European Union classify tungsten as a critical mineral, ensuring their supply chain security to support defense and high-end manufacturing.

Challenges and Continued Importance

Although tungsten rods are indispensable in industry, their production faces challenges such as high energy consumption, environmental pollution and resource scarcity. The development of green manufacturing technology and tungsten waste recycling technology has become the focus of the industry. However, these challenges have not diminished the importance of tungsten rods, but have led to technological advancements that will allow it to continue to play a central role in the industry of the future.

1.3 Historical Background and Development

As an important material in modern industry, the development process of tungsten rod is closely related to the discovery, purification technology and industrial application of tungsten. From the discovery of tungsten in the late 18th century to the widespread use of tungsten rod in the 21st century, the history of tungsten rod reflects the evolution of materials science, metallurgical technology, and industrial needs. The following is a detailed trace of the historical background of tungsten rod and the development trajectory of its technology and application.

Tungsten discovery and early research

The discovery of tungsten dates back to 1781, when the Swedish chemist Carl Wilhelm Scheele discovered the presence of tungsten acid by analyzing wolframite. In 1783, Spanish brothers Juan José and Fausto Elhuyar first isolated tungsten from tungsten acid and named it “tungsten” (Swedish for “heavy stone”), so named for its high density. Early tungsten research was mainly focused on chemical properties, limited to laboratory scale, and industrial applications of tungsten have not yet been carried out due to its high melting point and difficult to process.

In the mid-19th century, with the advancement of metallurgical technology, the potential industrial value of tungsten gradually emerged. In the 1850s, tungsten began to be tried in the production of alloy steels to enhance the hardness and wear resistance of the steel. However, the purification and molding technology of pure tungsten is still immature, which limits its wide application.

Initial industrialization of tungsten rods

The industrialization of tungsten rods began at the beginning of the 20th century and is closely related to the needs of the lighting industry. In 1904, Hungarian engineers Sandor Just and Franz Hanaman developed tungsten incandescent lamps to replace inefficient carbon filament lamps. Tungsten’s high melting point and low vapor pressure make it an ideal filament material, but early tungsten filaments are easily embrittlement, making it difficult to process into rods or filaments.

In 1909, William D. Coolidge of General Electric invented the preparation process of ductile tungsten to produce tungsten rods and tungsten wires with better toughness through powder metallurgy and high-temperature forging technology. This breakthrough enabled the mass production of tungsten rods, significantly reducing the cost of incandescent lamps and driving a revolution in the lighting industry. Kulich’s process forms the basis for modern tungsten rod production, including the core steps of powder pressing, sintering and texturing processing.

The application of tungsten rods in the 20th century expanded

In the first half of the 20th century, the application of tungsten rods expanded from lighting to several industrial fields.

Electronics: In the 1920s, tungsten rods were used in cathodes and electrodes for vacuum and X-ray tubes, and performed well in high-temperature electronics due to their high melting point and electrical conductivity.

Military industry: During World War I, tungsten was used to make high-strength alloy steels to enhance the performance of tank armor and artillery shells. During World War II, tungsten alloy rods began to be machined into armor-piercing cores, significantly increasing the effectiveness of anti-tank weapons.

Welding technology: In the 1940s, tungsten rods were developed as argon arc welding (TIG welding) electrodes, and thorium-doped tungsten rods (containing 2% thorium oxide) became the standard material in the welding industry due to their excellent arc stability.

During this period, the production technology of tungsten rods continued to improve. The optimization of powder metallurgy process improves the density and mechanical properties of tungsten rods, while the introduction of deformation processing technologies such as rotary forging and drawing greatly improves the dimensional accuracy and surface quality of tungsten rods.

The strategic position of the Cold War and tungsten rods

During the Cold War, tungsten rods became a strategic material for their applications in the defense and aerospace sectors. In the 1950s-1970s, tungsten alloy rods were widely used in jet engine turbine blades, missile components, and spacecraft counterweights. Both the U.S. and the Soviet Union listed tungsten as a critical resource, building stockpiles to ensure supply chain security. China’s tungsten industry also developed rapidly during this period, relying on rich tungsten ore resources, becoming the world’s major tungsten rod supplier.

In the 1960s, a breakthrough was made in the research and development of doped tungsten rods. Potassium-doped tungsten rod (WK) improves creep resistance at high temperature by adding trace amounts of potassium and is suitable for high-temperature furnace elements. Rare-earth tungsten rods (e.g., cerium-doped, lanthanum-doped) improve the durability and arc stability of the electrode, gradually replacing thorium-doped tungsten rods, which are slightly radioactive.

Modern tungsten rod technology and globalization

In the 21st century, the application and production technology of tungsten rod has entered a new stage.

Semiconductors and new energy: The use of tungsten rods in the manufacture of monocrystalline silicon, sapphire crystals and thin-film solar cells has proliferated. For example, tungsten rods are used as high-temperature furnace core rods and sputtering targets, supporting the rapid development of the semiconductor and photovoltaic industries.

Green manufacturing: With the improvement of environmental protection requirements, tungsten rod production began to adopt low-energy sintering technology and waste recycling process. For example, waste tungsten rods can be chemically purified to be remade into tungsten powder, reducing resource consumption.

New alloys and doping: Tungsten-nickel-copper alloy rods are used in medical devices due to their non-magnetic and high density, and lanthanum-doped tungsten rods (WL20) have become the mainstream choice for welding electrodes due to their environmental friendliness.

The global tungsten rod market is centered on China, accounting for more than 80% of global production. Some international companies have a presence in the high-end tungsten rod market, focusing on the production of high-precision and special tungsten rods. The formulation of international standards (e.g., ASTM B777, ISO 24370) and domestic standards (e.g., GB/T 4187-2017) has facilitated the standardized trade of tungsten rods.

Challenges and future of tungsten rod development

The development of tungsten rods faces challenges such as resource scarcity, environmental pressure and high cost. The environmental damage caused by tungsten mining has prompted countries to strengthen regulation, and the high melting point and high hardness of tungsten have increased the difficulty of processing and energy consumption. In the future, the development direction of tungsten rod industry includes:

New processes, such as plasma sintering and additive manufacturing (3D printing) for the production of tungsten rod parts with complex shapes.

New materials: develop low-toxicity doped tungsten rods to completely replace thorium-doped tungsten rods.

Circular economy: Increase tungsten recovery and reduce dependence on raw ore.

READ MORE: Encyclopedia of Tungsten Rods

===================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595