Directory

Chapter 1 Introduction

1.1 Definition and Overview of Thorium Tungsten Electrode

1.2 The Importance of Thorium Tungsten Electrode in the Welding Industry

1.3 Background of Research and Application

Chapter 2 Types of Thorium Tungsten Electrode

2.1 Thorium Tungsten Electrode Are Classified According to Thorium Oxide Content

2.1.1 WT10 (Yellow Paint)

2.1.2 WT20 (Red Paint)

2.1.3 WT30 (Purple Paint)

2.1.4 WT40 (Orange Paint)

2.2 Thorium Tungsten Electrode Are Classified According to Application Scenarios

2.2.1 Thorium Tungsten Electrode for DC Welding

2.2.2 Thorium Tungsten Electrode for AC Welding (Special Scene)

2.3 Comparison of Thorium Tungsten Electrode with Other Tungsten Electrode

2.3.1 Pure Tungsten Electrode

2.3.2 Cerium Tungsten Electrode

2.3.3 Lanthanum Tungsten Electrode

2.3.4 Zirconium Tungsten Electrode

2.3.5 Yttrium Tungsten Electrode

Chapter 3 Characteristics of Thorium Tungsten Electrode

3.1 Physical Properties of Thorium Tungsten Electrode

3.1.1 High Melting Point and Thermal Stability of Thorium Tungsten Electrode

3.1.2 Electron Work of Thorium Tungsten Electrode

3.1.3 Conductivity and Mechanical Properties of Thorium Tungsten Electrode

3.2 Chemical Properties of Thorium Tungsten Electrode

3.2.1 Oxidation Resistance of Thorium Tungsten Electrode

3.2.2 Chemical Stability of Thorium Tungsten Electrode

3.3 Welding Performance of Thorium Tungsten Electrode

3.3.1 Arc Initiation Performance of Thorium Tungsten Electrode

3.3.2 Arc Stability of Thorium Tungsten Electrode

3.3.3 Electrode Burn-Out Rate of Thorium Tungsten Electrode

3.3.4 Performance of Thorium Tungsten Electrode at High Load Currents

3.4 Radioactive Properties of Thorium Tungsten Electrode

3.4.1 Trace Radioactivity of Thorium Oxide

3.4.2 Health and Environmental Impacts

3.4.3 Comparison of Thorium Tungsten Electrode with Non-Radioactive Electrode

3.5 Thorium Tungsten Electrode MSDS from CTIA GROUP LTD

Chapter 4 Preparation and Production Technology of Thorium Tungsten Electrode

4.1 Preparation of Raw Materials for Thorium Tungsten Electrode

4.1.1 Selection and Purification of Tungsten Powder

4.1.2 Thorium Oxide Doping Process

4.2 Powder Metallurgy Process of Thorium Tungsten Electrode

4.2.1 Mixing and Pressing

4.2.2 Sintering Process

4.2.3 Heat Treatment and Grain Control

4.3 Rolling and Grinding Process of Thorium Tungsten Electrode

4.3.1 Forming of Electrode Rods

4.3.2 Surface Polishing and Precision Control

4.4 Quality Control of Thorium Tungsten Electrode

4.4.1 Ingredient Uniformity Testing

4.4.2 Dimensional and Surface Quality Inspection

4.5 Prevention and Control of Radioactive Contamination of Thorium Tungsten Electrode

4.5.1 Radioactive Waste Management in the Production Process

4.5.2 Protective Measures and Equipment Requirements

4.5.3 Treatment of Wastewater and Solid Waste

Chapter 5 Uses of Thorium Tungsten Electrode

5.1 Application of Thorium Tungsten Electrode in the Field of Welding

5.1.1 Tungsten Inert Gas (TIG) Welding

5.1.2 Plasma Welding

5.1.3 DC Anode Welding (Carbon Steel, Stainless Steel, Nickel Alloy, Titanium Alloy, etc.)

5.2 Application of Thorium Tungsten Electrode in Other Industries

5.2.1 Cathode Materials in Vacuum Electronics

5.2.2 Arc Cutting and Arc Initiation

5.3 Limitations of Thorium Tungsten Electrode Application Scenarios

5.3.1 Radioactive Use Scenarios

5.3.2 Application Trends of Alternative Electrode

Chapter 6 Production Equipment for Thorium Tungsten Electrode

6.1 Raw Material Processing Equipment for Thorium Tungsten Electrode

6.1.1 Tungsten Powder Grinding and Screening Equipment

6.1.2 Thorium Oxide Doping Equipment

6.2 Powder Metallurgy Equipment for Thorium Tungsten Electrode

6.2.1 Mixers

6.2.2 Presses

6.2.3 High Temperature Sintering Furnace

6.3 Forming and Processing Equipment for Thorium Tungsten Electrode

6.3.1 Calenders

6.3.2 Grinding and Polishing Equipment

6.4 Radioprotective Equipment for Thorium Tungsten Electrode

6.4.1 Special Grinder and Dust Removal System

6.4.2 Enclosures and Ventilation Equipment

6.4.3 Radioactive Waste Disposal Equipment

6.5 Testing Equipment for Thorium Tungsten Electrode

6.5.1 X-γ Radiation Dose Rate Detector

6.5.2 α, β Surface Contamination Detector

Chapter 7 Domestic and Foreign Standards for Thorium Tungsten Electrode

7.1 International Standards for Thorium Tungsten Electrode

7.1.1 ISO 6848:2015 (Classification and Requirements for Tungsten Electrode)

7.1.2 AWS A5.12/A5.12M (American Welding Institute Tungsten Electrode Specification)

7.1.3 EN 26848 (European Standard for Tungsten Electrode)

7.2 Domestic Standards for Thorium Tungsten Electrode

7.2.1 GB/T 4187-2017 (National Standard for Tungsten Electrode)

7.2.2 GB 18871-2002 (Basic Standard for Protection Against Ionizing Radiation and Safety of Radiation Sources)

7.2.3 Measures for Environmental Radiation Monitoring and Information Disclosure of Enterprises for the Development and Utilization of Associated Radioactive Minerals (for Trial Implementation)

7.3 Radioactive Safety Standards for Thorium Tungsten Electrode

7.3.1 Thorium-232 Exempt Activity Concentration (1 Bq/g)

7.3.2 Protection Requirements in Production and Use

Chapter 8 Detection Methods of Thorium Tungsten Electrode

8.1 Chemical Composition Detection of Thorium Tungsten Electrode

8.1.1 Thorium Oxide Content Analysis

8.1.2 Impurity Content Detection

8.2 Testing of Physical Properties of Thorium Tungsten Electrode

8.2.1 Density and Hardness Testing

8.2.2 Grain Structure Analysis

8.3 Radioactivity Detection of Thorium Tungsten Electrode

8.3.1 X-γ Radiation Dose Rate Detection

8.3.2 α, β Surface Contamination Detection

8.3.3 Environmental Radiation Monitoring

8.4 Welding Performance Test of Thorium Tungsten Electrode

8.4.1 Arc Performance Test

8.4.2 Arc Stability and Burn Rate Test

8.5 Testing Equipment and Calibration of Thorium Tungsten Electrode

8.5.1 Calibration Requirements for Testing Instruments

8.5.2 Testing Environment and Operation Specifications

Chapter 9 Advantages and Disadvantages of Thorium Tungsten Electrode

9.1 Advantages of Thorium Tungsten Electrode

9.1.1 Excellent Welding Performance

9.1.2 High Temperature Strength and Wear Resistance

9.2 Disadvantages of Thorium Tungsten Electrode

9.2.1 Risk of Radioactive Contamination

9.2.2 Environmental and Health Impacts

Chapter 10 Storage, Transportation and Safety Management of Thorium Tungsten Electrode

10.1 Storage Environment and Condition Requirements

10.2 Packaging Standards and Protective Measures

10.3 Safety Precautions During Transportation

10.4 Safety Management Practices for Radioactive Materials

10.5 Emergency Handling and Accident Prevention

Chapter 11 Future Development Trends and Challenges of Thorium Tungsten Electrode

11.1 Research and Development Progress of Alternative Materials for Thorium Tungsten Electrode

11.2 Environmental Protection and Radiological Safety Pressure

11.3 New Preparation Processes and Green Manufacturing

11.4 Improvement Direction of Thorium Tungsten Electrode Performance

11.5 Changes in Market Demand and Development of the Industrial Chain

11.6 Impact of Policies and Regulations and Compliance Development

Appendix

- Glossary

- References

Chapter 1 Introduction

1.1 Definition and overview of thorium tungsten electrode

Thorium tungsten electrode is an alloy electrode with high-purity tungsten as the matrix and doped with a small amount of thorium oxide (ThO₂, usually between 0.9% and 4.2%), which is widely used in high-precision welding processes such as tungsten inert gas shielded welding (TIG welding). Its main component, tungsten, has an extremely high melting point (about 3422°C) and excellent electrical conductivity, while the addition of thorium oxide significantly reduces the electron work of the electrode (about 2.63 eV), thereby improving the arc initiation performance and arc stability. Thorium tungsten electrodes are usually classified by different thorium oxide contents, and the most common models in the world include WT10 (0.9-1.2% ThO₂, yellow coating), WT20 (1.8-2.2% ThO₂, red coating tip), WT30 (2.8-3.2% ThO₂, purple applicator) and WT40 (3.8-4.2% ThO₂, orange-yellow applicator). These models are color-coded for easy differentiation in production and use.

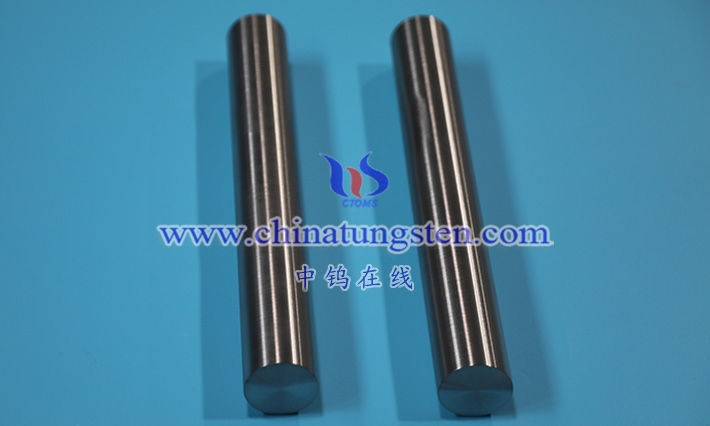

The appearance of thorium tungsten electrodes is rod-shaped, usually between 0.5 mm and 10 mm in diameter, and the length is generally 150 mm or 175 mm, and the surface is precision ground and polished to ensure stability during the welding process. Its unique properties stem from the high melting point of tungsten and the thermal electron emission capability of thorium oxide, which allows it to maintain a stable arc under high current loads while reducing electrode burnout. The doping of thorium oxide not only enhances the high temperature resistance of the electrode, but also makes it excellent in DC anode (DCEN) welding, especially suitable for the welding of carbon steel, stainless steel, nickel alloy and titanium alloy.

However, thorium tungsten electrodes are characterized by trace amounts of radioactivity (mainly α and β particle radiation due to their thorium oxide content, which makes them require special precautions during production, storage and use. Despite its low radioactivity levels (thorium-232 has an exempt activity concentration of 1 Bq/g), long-term exposure may still have potential health and environmental effects. Therefore, in recent years, non-radioactive electrodes such as cerium tungsten and lanthanum tungsten have gradually become substitutes, but thorium tungsten electrodes still occupy an important position in specific fields due to their excellent welding properties.

1.2 The importance of thorium tungsten electrodes in the welding industry

Thorium tungsten electrodes are of irreplaceable importance in the welding industry, especially in high-precision processes such as tungsten argon arc welding (TIG welding) and plasma welding. TIG welding is a welding method that uses an inert gas (such as argon or helium) to protect the arc and weld pool, and is widely used in the aerospace, nuclear industry, automobile manufacturing and shipbuilding industry. Thorium tungsten electrodes have become the preferred electrode material for TIG welding due to their excellent arc initiation performance and arc stability.

First of all, the thorium tungsten electrode performs well in DC anode welding. Its low electron escape work allows the electrode to easily initiate arcing, and the arc remains stable at high currents, reducing spatter and welding defects. This is especially important for welding metals with high melting points, such as titanium alloys and stainless steels. For example, in the aerospace industry, where the welding of titanium components requires extremely high precision and surface quality, thorium tungsten electrodes ensure uniformity and strength of the weld. In addition, the low burn-out rate of thorium tungsten electrodes under high current loads prolongs the service life of the electrodes and reduces production costs.

Secondly, the high conductivity and thermal stability of thorium tungsten electrodes make them suitable for welding a wide range of materials, including carbon steel, alloy steel, copper alloys, and nickel-based alloys. Electrodes with different thorium oxide contents, such as WT20 and WT40, can be selected according to the welding current and material type to meet different process needs. For example, WT20 is most widely used in medium-current welding due to its moderate thorium oxide content (1.8-2.2%), while WT40 is more suitable for high-current, heavy-duty industrial scenarios.

In addition, thorium tungsten electrodes also have important applications in plasma welding and arc cutting. Plasma welding requires the electrode to maintain stability in a high-temperature and high-pressure plasma environment, and the high-temperature resistance of thorium tungsten electrodes makes it an ideal choice. In arc cutting, thorium tungsten electrodes can provide a high-strength arc to ensure cutting efficiency and precision. These properties make thorium tungsten electrodes indispensable in modern industry, and although their radioactivity problems have led to the study of alternative materials, their advantages in specific high-demand scenarios are still difficult to completely replace.

1.3 Background of research and application

The development and application of thorium tungsten electrodes began in the early 20th century and gradually developed with the rise of arc welding technology. Tungsten is an ideal choice for electrode materials due to its high melting point and excellent electrical conductivity, but the difficulty of arc initiation and arc instability of pure tungsten electrodes at high currents limit its application. In the 30s of the 20th century, researchers found that the performance of tungsten electrodes could be significantly improved by doping a small amount of thorium oxide. The discovery that the low electron work of thorium oxide reduces the energy required for arc initiation while improving the durability of the electrode at high temperatures, which has led to the widespread application of thorium tungsten electrodes.

In the decades that followed, the preparation process of thorium tungsten electrodes continued to improve. The introduction of powder metallurgy technology has made it possible to have a uniform distribution of thorium oxide, which improves the quality and consistency of the electrodes. In the 80s of the 20th century, with the popularization of TIG welding technology, thorium tungsten electrodes became the mainstream materials in the welding industry, and international standards (such as ISO 6848 and AWS A5.12) were also formulated to regulate their production and use.

However, the radioactivity of thorium tungsten electrodes has gradually attracted attention. Thorium-232 in thorium oxide is a naturally occurring radioactive element, and its decay releases α particles and small amounts of β and γ radiation. Despite its low levels of radioactivity, it can still pose a potential risk to worker health and the environment during production and use, such as dust generated during electrode grinding. Since the 90s of the 20th century, European and American countries have begun to promote the research and development of non-radioactive electrodes, and cerium tungsten electrodes (WC20) and lanthanum tungsten electrodes (WL20) have gradually entered the market. These alternative electrodes are close to thorium tungsten electrodes in terms of performance and have no radioactive risk, so they are gradually replacing thorium tungsten electrodes in some areas.

Despite this, thorium tungsten electrodes still have unique advantages in some demanding areas. For example, in the nuclear industry and aerospace, thorium tungsten electrodes are still the material of choice due to their excellent arc stability and high temperature resistance. In recent years, the focus of research has shifted to optimizing the production process of thorium tungsten electrodes to reduce radioactive contamination, while exploring new doping materials to further improve performance. In addition, with increasingly stringent environmental regulations, the production and use of thorium tungsten electrodes are more restricted, prompting the industry to develop safer and environmentally friendly alternatives.

Globally, the application and research of thorium tungsten electrodes continues. As a major country in tungsten resources, China occupies an important position in the production and export of thorium tungsten electrodes, and related enterprises continue to improve their production processes to meet international standards. At the same time, the demand for thorium tungsten electrodes in the international welding industry remains strong, especially in developing countries and in specific industrial sectors. In the future, with the advancement of new materials and processes, the role of thorium tungsten electrodes may change, but its important position in the history of welding technology is undeniable.

READ MORE: Encyclopedia of Thorium Tungsten Electrode

===================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595