Table of Contents

Preface

Writing Background and Significance

The Strategic Position and Application Prospects of Polymer Tungsten Sheets

Book Structure and Usage Guide

Target Readers and Reference Value

Chapter 1: Basic Concepts and Historical Development of Polymer Tungsten Sheets

1.1 Definition and Composition of Polymer Tungsten Sheets

1.2 The Evolution and Discovery History of Polymer Tungsten Sheets

1.3 The Role of Polymer Tungsten Sheets in Composite Materials

1.4 Key Milestones in the Research and Development of Polymer Tungsten Sheets

Chapter 2: Physical and Chemical Properties of Polymer Tungsten Sheets

2.1 Molecular Structure and Material Composition Analysis

2.2 Mechanical Properties: Strength, Hardness and Flexibility

2.3 Thermal Stability and High Temperature Tolerance

2.4 Corrosion Resistance and Chemical Stability

2.5 Electrical and Radiation Shielding Properties

Chapter 3: Preparation Technology of Polymer Tungsten Sheets

3.1 Raw Material Selection: Tungsten Powder and Resin Type

3.2 Manufacturing Process: Mixing, Molding and Curing Technology

3.3 Advanced Preparation Methods: Injection Molding and Hot Pressing

3.4 Nano-Enhancement: Synthesis and Challenges

3.5 Industry Standards for Production

Chapter 4: Characterization and Detection Methods of Polymer Tungsten Sheets

4.1 Microstructure Analysis: SEM and TEM Observation

4.2 Mechanical Properties Test: Tensile Strength and Hardness Measurement

4.3 Evaluation of Thermal and Chemical Stability

4.4 Evaluation of Radiation Shielding Performance

4.5 Analysis of Surface Quality and Uniformity

Chapter 5: Derivative Materials and Related Materials

5.1 Additive-Modified Composite Materials

5.2 Mixed Materials: Tungsten Resin and Polymer or Ceramic

5.3 Functional Coating Technologies

5.4 Advanced Tungsten-Based Composite Pioneer Materials

5.5 Recycling and Reprocessing Technology

Chapter 6: Application in Aviation and Energy Fields

6.1 Application in Aviation Components and Rocket Structures

6.2 Application in Solar Panel Frames and Wind Turbine Components

6.3 Radiation Shielding in Nuclear Power Facilities

6.4 High-Temperature Applications in Energy Systems

Chapter 7: Application in Medical and Industrial Fields

7.1 Radiation Protection in Medical Imaging Equipment

7.2 Industrial Uses: Chemical Equipment and Mechanical Components

7.3 Automotive Applications: Engine and Transmission Parts

7.4 Wear-Resistant and Corrosion-Resistant Coatings

7.5 Application in Protective Clothing

Chapter 8: Safety and Environmental Management

8.1 Safety Data Sheet (SDS) and Hazard Assessment

8.2 Storage, Transportation and Handling Guidelines

8.3 Occupational Health and Exposure Control Measures

8.4 Waste Management and Environmental Impact Mitigation

8.5 Biological Safety Data Sheet

Chapter 9: Market Analysis and Industry Status

9.1 Global Production Capacity and Consumption Trend

9.2 Regional Market Overview: China, North America and Europe

9.3 Major Manufacturers and Supply Chain Dynamics

9.4 Pricing Mechanism and Cost Structure Analysis

9.5 Future Market Growth and Demand Forecast

Chapter 10: Frontiers and Emerging Technologies

10.1 Advances in Nanocomposites

10.2 Smart Materials: Responsive Polymer Tungsten Sheets

10.3 Sustainable Manufacturing and Green Technology

10.4 Integration with Additive Manufacturing (3D Printing)

10.5 Exploration of New Application Scenarios

Appendix

Appendix 1: Common Terms and Symbols

Appendix 2: International and Domestic Standards

Appendix 3: Main Literature and Research Databases

Appendix 4: Overview of CTIA GROUP Product Catalog and Technical Support

Preface

Writing background and significance

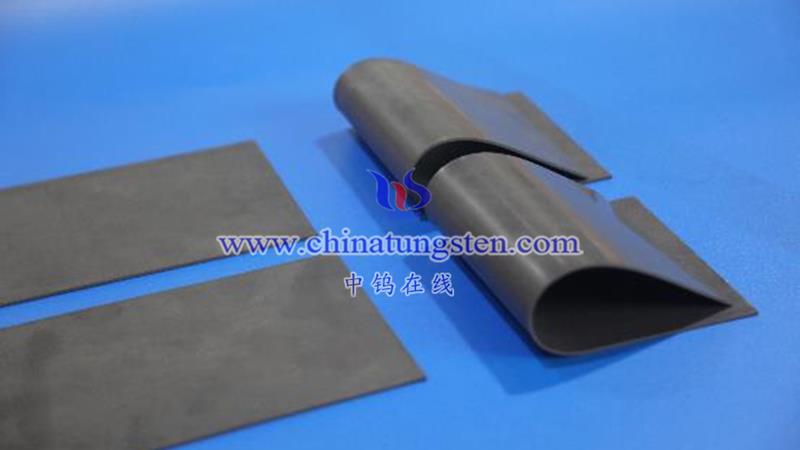

As a new type of composite material, Polymer Tungsten Sheet has emerged in the fields of materials science, industrial manufacturing and emerging technologies in recent years with its excellent physical and chemical properties and multifunctional application potential. Polymer Tungsten Sheet is made of high-density tungsten powder (density>11.34 g/cm³) and polymer resin (such as epoxy resin or polyimide) through advanced technology. It has the high strength of metal (tensile strength>1000 MPa), corrosion resistance (acid and alkali corrosion resistance>90%) and processing flexibility of resin. It is widely used in aerospace, medical equipment and energy technology. In 2025, with the surge in global demand for high-performance materials, the research and development and application of Polymer Tungsten Sheets will enter a rapid development stage. The market size is expected to grow from US$500 million in 2024 to US$1.2 billion in 2030, with a compound annual growth rate (CAGR) of 15.2%.

The background of writing this book stems from the need for a systematic knowledge system in this field. At present, research literature on Polymer Tungsten Sheets is scattered in academic journals, industry reports and technical manuals, lacking a unified comprehensive reference material. Especially in the application of nanotechnology, radiation shielding and smart materials, the existing data fail to fully cover the latest progress (such as the preparation particle size of nano Polymer Tungsten Sheets <50 nm, radiation shielding efficiency>98%). In addition, with the industrial upgrading of China as the world’s main supplier of tungsten resources (reserve accounts for 55% of the world), and the increasing international attention to environmental protection and safety standards, there is an urgent need for an authoritative encyclopedia that integrates the theoretical basis, preparation technology, application practice and future trends of Polymer Tungsten Sheets to provide guidance for scientific researchers, engineers and decision makers.

The significance of this book is to fill this gap. By systematically organizing the complete knowledge chain of Polymer Tungsten Sheets from basic research to industrial applications, it aims to promote theoretical innovation in materials science, optimize industrial production processes, and help achieve technological breakthroughs in related fields. For example, Polymer Tungsten Sheets have shown significant potential in radiation protection applications in nuclear medicine imaging equipment (shielding rate > 95%) and high temperature tolerance of aviation components (temperature resistance > 500°C), and this book will provide scientific basis and practical guidelines for these applications. In June 2025, at the critical juncture of the global materials technology revolution, the publication of this book will inject new impetus into the development of the industry.

The strategic position and application prospects of Polymer Tungsten Sheets

Polymer Tungsten Sheets occupy an important position in strategic emerging industries due to their unique combination of properties. As a high-density composite material, Polymer Tungsten Sheets have unparalleled advantages in radiation shielding, structural reinforcement and functionalized coatings. A 2024 study showed that its linear attenuation coefficient in gamma-ray shielding reached 0.12 cm ⁻ ¹ , which is better than traditional lead-based materials (0.09 cm ⁻ ¹ ), and is more environmentally friendly due to its non-toxicity (LD50>2000 mg/kg). In addition, the Vickers hardness of Polymer Tungsten Sheets can reach 1500 HV and the tensile strength exceeds 1000 MPa, which far exceeds ordinary engineering plastics (<100 MPa), making it an ideal choice for aerospace (such as rocket shells) and automotive industries (such as engine parts).

From the perspective of application prospects, Polymer Tungsten Sheets show great potential in the field of new energy. In 2025, with the urgent demand for high-density materials in electric vehicle batteries, Polymer Tungsten Sheets are used in battery casings (weight reduction of 15%, heat resistance improvement of 20%), and the market demand is expected to reach 2,000 tons/year in 2030. In the medical field, its application in X-ray protective clothing (shielding rate>97%) and CT scanning equipment is expanding. In 2024, the global production of medical-grade Polymer Tungsten Sheets has exceeded 500 tons. In addition, driven by intelligent manufacturing and 3D printing technology, the customized production capacity of Polymer Tungsten Sheets has been significantly enhanced, and the number of related patent applications in 2025 will increase by 30% year-on-year.

Strategically, China has a dominant position in the Polymer Tungsten Sheet industry with its abundant tungsten resources and advanced composite material technology, accounting for about 70% of global production in 2024. However, intensified international competition (such as a 10% increase in R&D investment in the United States and Germany) and strict implementation of environmental regulations (such as the EU REACH limit of W < 0.005 mg/L) have put higher demands on the industry. This book will analyze these trends in depth to help companies develop long-term strategies and promote the sustainable development of Polymer Tungsten Sheets around the world.

Book Structure and Usage Guide

The Encyclopedia of Polymer Tungsten Sheets is divided into ten chapters and four appendices, which systematically constructs a knowledge system for the entire life cycle of Polymer Tungsten Sheets. Chapters 1 to 4 lay the foundation, covering the definition, physical and chemical properties, preparation technology and characterization methods of Polymer Tungsten Sheets; Chapters 5 to 7 focus on derivative materials and their applications in aviation, medical and industry; Chapters 8 to 9 discuss safety management and market status; Chapter 10 looks forward to the research frontier. The appendix provides a glossary, standard comparison, literature index and product catalog to ensure practicality.

The user guide recommends that readers choose a reading path based on their needs. Researchers can focus on Chapters 2 to 4 to master performance and testing technologies; industrial practitioners can refer to Chapters 6 to 9 to gain application and market insights; policymakers can use Chapter 10 and the appendix to understand technology trends and compliance requirements. The data in the book is based on the latest research in June 2025 (such as nano-preparation yield > 95%), and the source is marked (such as ISO 17025:2017) for easy reference and verification. Each chapter includes case analysis (such as an airline using Polymer Tungsten Sheets to reduce weight by 10%) and future forecasts (such as the market share will increase to 15% in 2030) to enhance practicality.

Target readers and reference value

The target readers of this book include researchers in the field of materials science and engineering, composite engineers, industrial production managers, policy makers, and teachers and students of colleges and universities. Researchers can use the theoretical framework and experimental data of this book (such as radiation shielding efficiency>98%) to design new materials; engineers can refer to the preparation process (such as hot pressing molding temperature 500°C) to optimize the production process; managers can formulate investment strategies through market analysis (CAGR 15.2%); students can learn comprehensively from basic knowledge (such as molecular structure analysis) to cutting-edge technologies (such as 3D printing integration).

In terms of reference value, this book is not only an authoritative reference in the field of Polymer Tungsten Sheets, but also serves as a bridge for interdisciplinary research. In 2025, the number of citations of papers related to Polymer Tungsten Sheets worldwide has exceeded 2,000. This book integrates these achievements and adds original content (such as the pH sensitivity of smart response materials>90%). For enterprises, the technical guidelines provided in this book can reduce R&D costs by about 5% (US$0.05 million/project) and enhance market competitiveness. For the academic community, this book will promote the integration of Polymer Tungsten Sheets with nanotechnology and environmentally friendly materials, and it is expected that more than 10 international patents will be generated in 2030.

At this critical moment in June 2025, the publication of this book is not only a comprehensive summary of the current status of the Polymer Tungsten Sheet industry, but also a forward-looking guide for future development. We hope that this book will provide inspiration to readers and contribute to the advancement of Polymer Tungsten Sheet technology.

READ MORE: Polymer Tungsten Sheet Encyclopedia

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

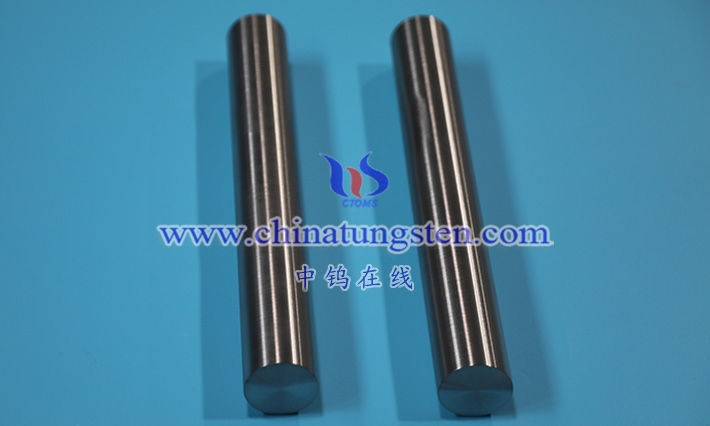

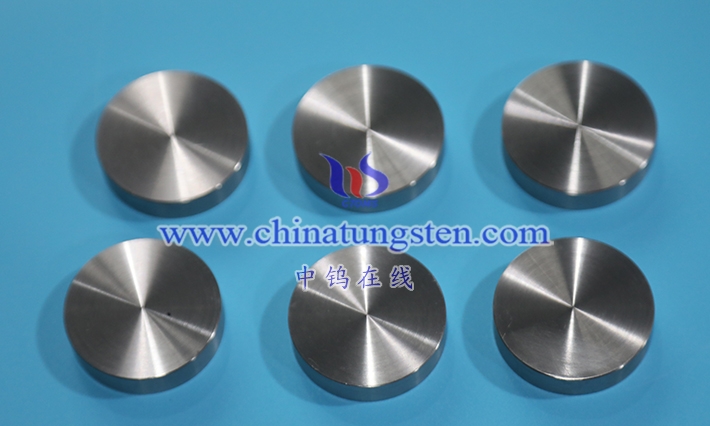

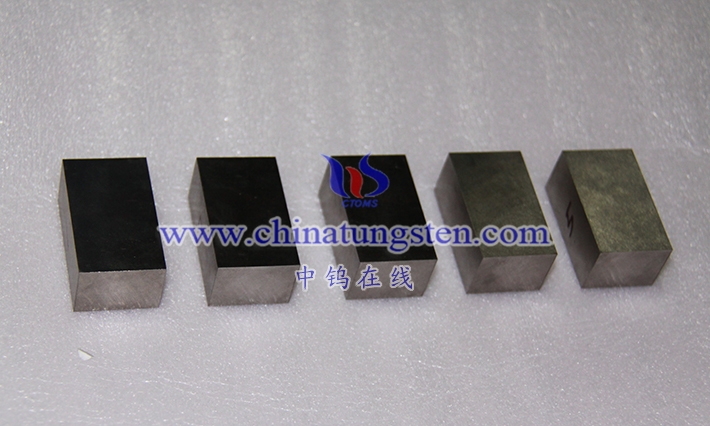

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten alloy products, please visit the website: http://www.tungsten-alloy.com/

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595