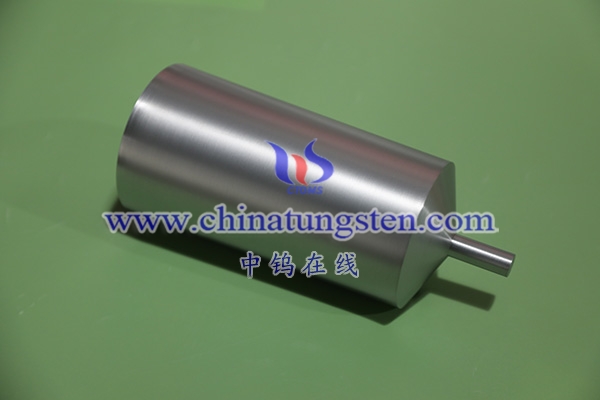

Molybdenum crucibles can be customized in batches. Molybdenum crucibles are widely used in metallurgy, semiconductor manufacturing, chemical industry, scientific research and other fields due to their high melting point, excellent thermal conductivity and corrosion resistance. Many manufacturers support batch customization according to customer needs.

Customization capability description

Material and purity

Molybdenum crucibles are usually made of high-purity molybdenum metal (such as Mo1, MoLa, Moly361 and other brands), with a purity of more than 99.95%, ensuring stable product performance.

Some manufacturers can provide customized services for special materials such as tungsten-molybdenum alloys.

Specifications and dimensions

Diameter range: 50mm to 500mm, height range: 50mm to 600mm, support customization according to customer drawings or specifications.

Production process

Customized processes include forging, rolling, wire cutting, machining, etc. to ensure product accuracy and performance.

For example, sintered molybdenum crucibles, machined molybdenum crucibles, welded molybdenum crucibles, etc. can all be produced on demand.

Surface treatment

Polishing or coating can be performed as required to improve corrosion resistance and service life.

Customization process and cycle

Demand communication

Customers provide specific specifications, materials, quantities, usage scenarios and other requirements.

Manufacturers provide technical solutions and quotations based on demand.

Sample confirmation

Some manufacturers can provide samples for customers to test and confirm that the performance meets the requirements.

Mass production

After signing the contract, the manufacturer arranges production and the delivery cycle is generally 15 to 30 days. The specific time depends on the order quantity and the complexity of the production process.

Quality inspection and delivery

After production is completed, strict quality inspection is carried out to ensure that the products meet the standards before shipment.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595