To evaluate the cost performance of molybdenum crucibles, a systematic analysis is required from five dimensions: performance parameters, price level, quality stability, supplier services and comprehensive costs. The following are the specific methods:

1. Performance parameter evaluation

Material and purity

Molybdenum crucibles must use Mo-1 molybdenum powder (purity ≥ 99.95%). High purity can reduce the risk of impurities introduced and improve product yield.

Physical properties

Density: ≥9.8 g/cm³, high density can improve thermal shock resistance.

Thermal expansion coefficient: must be lower than 5.3×10 ⁻⁶ / ℃ to ensure high temperature dimensional stability.

Creep resistance: Need to pass 1500℃/100 hours creep test to ensure long-term use without deformation.

Processing accuracy

The dimensional tolerance must be controlled within ± 0.1mm, and the roughness Ra ≤ 1.6μm to ensure matching with the heating equipment.

2. Price Level Comparison

Market price range

Small size (diameter 50-100mm) price: 300-800 yuan/piece.

Large size (diameter 200-500mm) price: 2000-8000 yuan/piece.

Cost composition analysis

Raw material costs account for about 60%, processing costs account for about 30%, and management/profit account for about 10%.

3. Quality stability assessment

Production consistency

Suppliers are required to provide batch consistency reports, including data such as dimensional tolerance, density fluctuation, and oxidation weight gain rate.

Quality Certification

We give priority to suppliers that have passed ISO 9001 and ISO 14001 certification to ensure a complete quality management system.

======================================================================

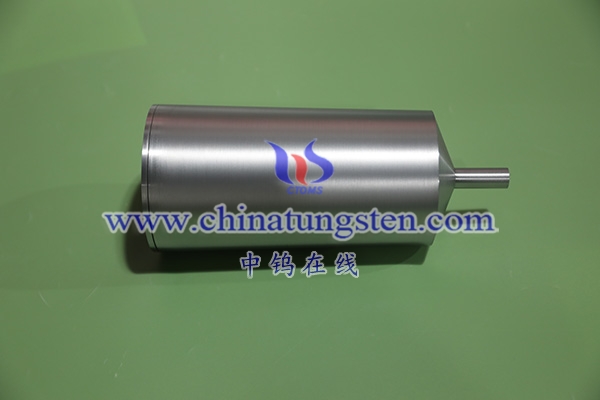

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595