As an indispensable tool in high-temperature metallurgy, crystal growth and high-end material preparation, molybdenum crucible will continue to evolve with the progress of new material technology, energy technology and manufacturing process. The following are the main trends of molybdenum crucible development in the future:

1. High-purification and ultra-purification development

molybdenum crucibles are constantly increasing, especially in the fields of semiconductors, optoelectronics and high-end displays (such as OLED), where micro impurities may seriously affect product performance. In the future:

Vacuum smelting and electron beam melting are more often used to improve the purity of molybdenum;

Achieve commercialization of crucibles made of molybdenum materials above 5N grade (99.999%);

Strengthen the precise control and detection technology of impurity elements (such as Fe, Ni, Si, O, C, etc.).

2. Complex structure and customized production

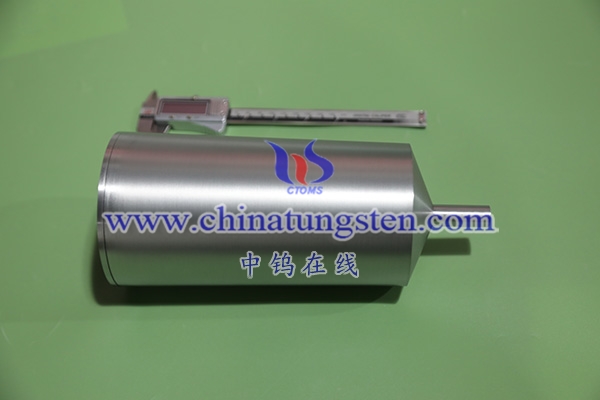

As the application scenarios become more diverse, molybdenum crucibles have also evolved from traditional cylindrical and conical shapes to:

Specialized structures (such as multi-cavity, multi-section connection structure) to meet different process requirements;

Integrated components, such as a crucible and a heating element formed in one piece;

Support small batch and multi-specification customized production to meet scientific research and special industrial applications.

3. Development of surface engineering and antioxidant technology

Molybdenum is easily oxidized at high temperatures in the air, which limits its high-temperature application in oxygen environments. In the future, the development will focus on:

Surface anti-oxidation coating technology, such as aluminum oxide (Al₂O₃) and silicon nitride (Si₃N₄) ceramic coatings;

Plasma spraying and CVD/PVD coating processes improve density and adhesion;

Bimetallic composite material technology, such as a molybdenum crucible coated with an oxidation-resistant metal layer such as platinum or tantalum.

4. Powder Metallurgy and Additive Manufacturing (3D Printing)

molybdenum crucible products with complex shapes, high precision or continuous and integrated structures, we will explore the following in the future:

Molybdenum crucibles are prepared by molybdenum powder metallurgy to improve density and structural uniformity;

Metal 3D printing (such as SLM or EBM technology) produces molybdenum crucibles, which improves flexibility and molding complexity, and is especially suitable for small batches of high-precision instruments for scientific research.

5. Performance upgrade and functional integration

In addition to the traditional high temperature container function, molybdenum crucibles will also have more functions in the future, such as:

Conductivity optimization design: used as electrode material in electric heating systems;

Structural and functional integration: integrated thermal field control, temperature monitoring (embedded thermocouple) and other modules;

Magnetic field or plasma compatible design: serving plasma furnaces and magnetron sputtering equipment.

6. Green manufacturing and sustainable recycling

In order to reduce costs and environmental impact, molybdenum crucible manufacturing and waste treatment will develop towards green development:

The production process has low energy consumption and less pollution;

Emphasis on the construction of molybdenum recycling and reuse system, such as laser marking to trace the source of materials;

Increase service life and reduce unit material consumption.

7. Market expansion and deepening of application areas

With the rise of emerging industries, the application scope of molybdenum crucibles will be further expanded:

Third-generation semiconductor (such as SiC, GaN) crystal growth equipment;

Experiment and preparation of high temperature alloys for aerospace engines;

Thermal treatment of new energy materials (such as sodium ion batteries and solid-state batteries);

Ultra-high temperature ceramics and functional materials melting;

of biomedical metal alloys (such as titanium-molybdenum materials).

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595