Molybdenum crucibles can fully participate in and integrate into the intelligent manufacturing system. Although it is a passive component (i.e., non-electronic or intelligent device), in the current “intelligent manufacturing” and “industry 4.0” system, molybdenum crucibles are key high temperature and corrosion resistant process units, and their use, manufacturing and monitoring processes are increasingly being incorporated into intelligent systems to improve efficiency, quality and traceability. The following are specific applications and integration methods:

1. The role of molybdenum crucible in intelligent manufacturing

1. Digitally managed as key consumables/process components

In crystal growth, vacuum melting, powder metallurgy and other systems, molybdenum crucibles serve as high-temperature reaction vessels;

The number of times each crucible is used, the number of thermal cycles, the surface condition, the temperature history, etc. can be tracked and managed by RFID/QR code;

The system can determine its remaining life based on the data and achieve predictive maintenance.

2. Participate in closed-loop control systems

In semiconductor or high-end ceramic production lines, the state of the molybdenum crucible carrying the melt directly affects the product quality;

The temperature distribution inside the crucible and the changes in the liquid level can be monitored in real time through infrared temperature measurement, thermal imagers, optical sensors, etc., and the heater and lifting system can be controlled in a linked manner.

2. Intelligent integration of molybdenum crucible manufacturing links

1. Digital Twin Technology

Build a digital twin model for each molybdenum crucible to track its entire life cycle from raw materials to processing, heat treatment, factory delivery, use, and retirement;

It can simulate thermal stress distribution, deformation behavior, fatigue limit, etc., to assist in improving the design and manufacturing process.

2. Process automation and process monitoring

Use CNC system for high-precision processing (turning, grinding, polishing);

Monitoring of crucible geometry using laser scanners;

Automatically detect defects using X-ray, ultrasonic flaw detection, etc.

3. Quality control intelligent decision-making system

Upload manual inspection data, machining logs, heat treatment temperature curves, and microstructure photos to the database;

Use machine learning to analyze product consistency and provide early warning of potential defects or return risks.

3. Future Trends and Development Directions

IoT + molybdenum crucible: Integrate sensors into the crucible support frame or thermal field structure to monitor the crucible surface temperature and stress in real time.

AI + process parameter optimization: Use artificial intelligence to analyze large amounts of experimental data to optimize crucible usage conditions and material replacement cycles.

Green manufacturing and traceability: Record the raw material source and processing track of each molybdenum crucible, in line with sustainable manufacturing and ESG requirements.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

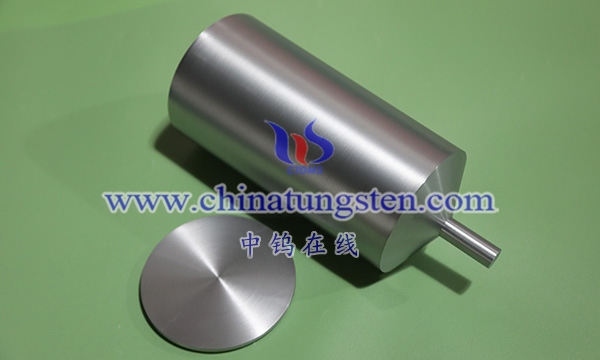

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595