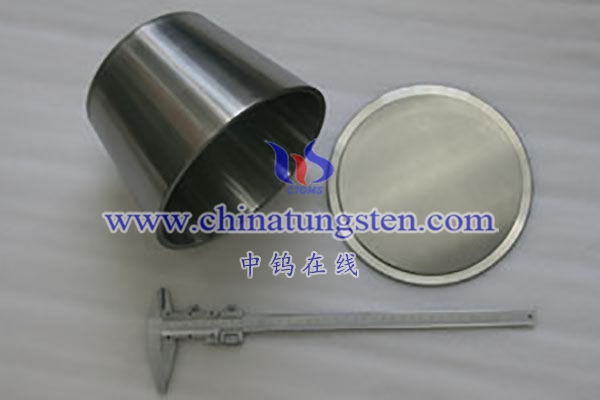

Molybdenum crucibles in high-throughput experimental design have certain advantages, especially in those experiments that require high temperature and chemical stability. High-throughput experiments usually require fast and precise operations between multiple samples and the ability to work stably in high temperature environments. Molybdenum crucibles have some characteristics that make them suitable for high-throughput experimental design. The specific advantages are as follows:

1. High temperature stability

Molybdenum crucibles can withstand extremely high temperatures (up to 3000°C), which is essential for many high-throughput experiments, especially those involving high-temperature reactions or material synthesis. Molybdenum ‘s high-temperature resistance enables it to withstand long-term high-temperature operations in high-throughput experiments without damage, ensuring the reliability of experimental results.

2. Good thermal conductivity

Molybdenum crucibles have excellent thermal conductivity, which helps to quickly heat and evenly distribute heat during experiments. This is especially important for high-throughput experiments, because multiple samples need to be heated and processed under the same conditions to ensure the accuracy and consistency of experimental results.

3. Chemical stability

Molybdenum crucibles have good chemical stability and can react with a variety of chemicals at high temperatures without corrosion. This makes it very suitable for use in high-throughput experiments, especially in experiments that need to handle different chemical reactions. The chemical stability of molybdenum ensures that there will be no contamination problems caused by the crucible material itself in the experiment.

4. Efficient sample processing

In high-throughput experimental design, it is often necessary to process a large number of samples and maintain consistent operating conditions. Molybdenum crucibles are suitable for parallel processing of multiple samples and can provide a stable and uniform heating environment under the same experimental conditions, helping to improve experimental efficiency.

5. Adapt to various atmospheres

Molybdenum crucibles can be used in a variety of atmospheres (such as inert gas, vacuum or specific chemical atmosphere), which is very important for reaction atmosphere control in high-throughput experimental design. For example, molybdenum crucibles can be heated in an atmosphere such as argon or nitrogen to avoid oxidation or other adverse reactions.

6. Durability and reusability

The durability and reusability of molybdenum crucibles make it possible to reduce costs in high-throughput experiments and reduce the frequency of changing crucibles during experiments. Molybdenum crucibles can maintain their stability and reliability even during multiple experimental cycles.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595