The connection between molybdenum crucibles and artificial intelligence (AI) experimental platforms is mainly reflected in the integration of high-temperature material preparation and AI-driven experimental optimization. In modern materials science and intelligent manufacturing, molybdenum crucibles, as high-performance reaction vessels, together with AI technology, form the core hardware-software collaboration foundation of the “intelligent experimental system”, promoting the intelligent transformation from experimental automation to material discovery.

1. AI is used for experimental design and data analysis, and molybdenum crucible is used as a physical reaction carrier

In high-throughput experiments or combined material experiments, the AI system designs experimental parameters (such as temperature, time, and raw material ratio) through algorithms, and the molybdenum crucible completes the corresponding high-temperature synthesis or smelting process.

After the experimental products are measured, AI analyzes the results and optimizes the next round of experiments to achieve a “closed-loop learning experiment.”

2. AI-assisted molybdenum crucible life management and fault prediction

The sensor data on the molybdenum crucible (temperature distribution, thermal stress, number of uses, etc.) is input into the AI system to train the model to identify its “health status”.

AI can predict the fatigue point of a crucible or warn of impending cracks, deformation or oxidation.

3. AI-driven adaptive furnace temperature control system, coordinating with molybdenum crucible to optimize process window

Based on historical process data and sensor feedback, AI can adjust the power distribution, atmosphere composition, heating rate, etc. in the furnace, so that the molybdenum crucible is in a better thermal field environment and reduce stress concentration and loss.

4. Molybdenum crucible experimental data provides a training basis for AI material science models

During high-temperature synthesis, smelting or reaction processes, the experimental data (product type, process parameters, etc.) generated by the molybdenum crucible is the basis for AI to predict material properties and perform performance modeling.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

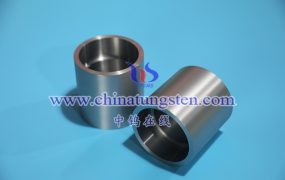

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595