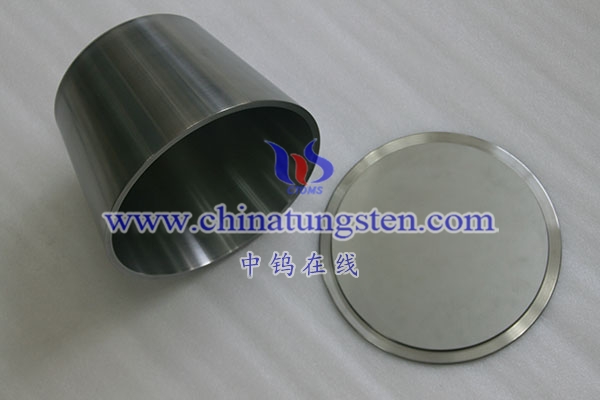

Molybdenum crucibles are very suitable for the development of a new generation of thermoelectric materials, especially in experiments that require material synthesis, smelting or heat treatment in a high temperature, inert, high-purity environment. Their unique physical and chemical stability makes them an ideal choice.

Why are molybdenum crucibles suitable for thermoelectric material development?

1. High temperature tolerance

New thermoelectric materials such as silicon-germanium (SiGe) alloys, **oxide thermoelectrics (such as Ca₃Co₄O₉) or chalcogenides (such as SnSe, PbTe) usually need to be sintered or melted at temperatures as high as 1000℃~2000℃.

Molybdenum crucible has a high melting point (2620°C) and can work safely in vacuum, high-purity inert atmosphere or hydrogen environment, and is suitable for high-temperature heat treatment.

2. Chemical inertness and low pollution

Molybdenum is non -reactive to most thermoelectric materials and is not easily introduced with impurities. It is particularly suitable for thermoelectric systems that are sensitive to doping or require high purity (such as Bi₂Te₃, Mg₂Si, etc.) .

3. Good thermal conductivity

The performance of thermoelectric materials strongly depends on temperature difference control. Molybdenum has excellent thermal conductivity, which helps the sample to be heated evenly and improves experimental reproducibility.

4. Suitable for vacuum and atmosphere control experiments

Most thermoelectric materials need to be processed in a vacuum or inert gas (such as Ar, N₂) to prevent oxidation. Molybdenum crucibles are extremely stable in such environments and can be used for closed melting or evaporation experiments.

In which thermoelectric material research have molybdenum crucibles been used?

Mg ₂ Si, Mg ₃ Sb ₂ series: high-performance n-type thermoelectric materials, need to be synthesized at high temperature in an inert environment, and molybdenum crucibles are often used.

PbTe, SnSe, Bi₂Te₃ series: used for fine smelting and crystal growth, requiring low pollution and anti-volatility.

melting point oxide thermoelectric materials (such as SrTiO₃ derivatives): Molybdenum crucibles can be used as linings or reaction vessels in oxidizing atmospheres.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595