The production process of tungsten needles involves several steps, which can vary depending on the desired shape, size, and properties of the final product. Here are the general steps involved in producing tungsten needles:

Powder preparation: Tungsten powder is first prepared through a process called reduction, where tungsten oxide is reduced using hydrogen gas to form tungsten powder.

Mixing: The tungsten powder is then mixed with a small amount of binding agent to form a homogeneous mixture.

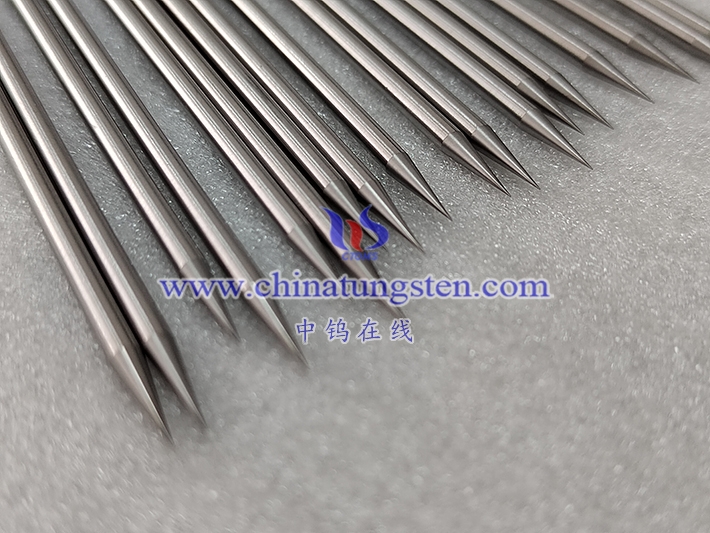

Shaping: The mixture is shaped into the desired form using a process such as extrusion, pressing, or injection molding. The shaping process produces a green body, which is a soft and pliable form of the tungsten material.

Sintering: The green body is then heated to high temperatures in a vacuum or inert gas environment, a process called sintering. Sintering fuses the tungsten particles together, creating a dense, solid material.

Machining: The sintered tungsten material is then machined to the desired shape and size using processes such as grinding, cutting, and polishing. This process can be challenging due to the hardness and brittleness of tungsten.

Cleaning: The tungsten needle is then cleaned to remove any residual impurities, such as oils and debris, that may have accumulated during the machining process.

Inspection: The final step involves inspecting the tungsten needle for defects, such as cracks, burrs, and other imperfections, to ensure it meets the required specifications.

The production process of tungsten needles requires specialized equipment and expertise, and it can be a time-consuming and expensive process. However, tungsten needles have unique properties that make them useful in a variety of applications.