The post-processing technology of tungsten-nickel-iron alloy refers to a series of processing and treatment operations carried out on alloy products after sintering, aiming to further improve their performance, precision and surface quality to meet the specific requirements of different application scenarios. Post-processing technologies mainly include heat treatment, mechanical processing, surface treatment, etc. According to the application and performance requirements of alloy products, corresponding treatment methods can be selected.

Heat treatment is an important link in post-processing. By heating, holding and cooling the sintered alloy, its internal structure is adjusted to optimize mechanical properties. A common heat treatment method is annealing, in which the alloy is heated to a certain temperature (usually 800 – 1000℃), held for a period of time and then slowly cooled, which can eliminate internal stress generated during sintering and improve the toughness and processability of the alloy; for alloys that need to improve strength and hardness, aging treatment can be used, in which the alloy is held at a lower temperature (such as 400 – 600℃) to promote the precipitation of fine strengthening phases in the alloy, thereby improving its tensile strength and hardness.

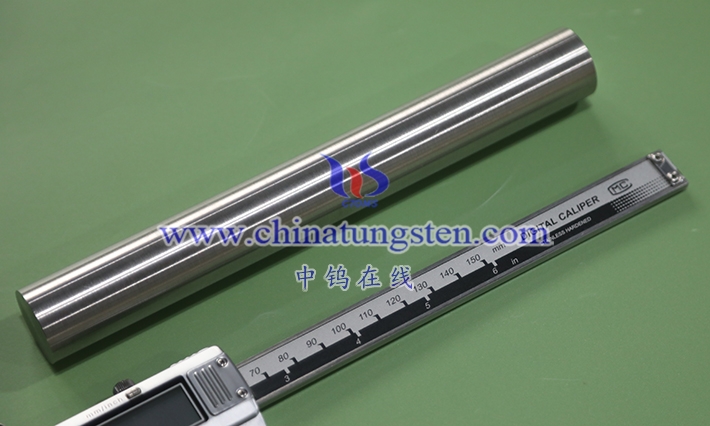

Mechanical processing is used to process sintered alloy products into parts with precise dimensions and complex shapes. Common processing methods include turning, milling, grinding, drilling, etc. Due to the high hardness and strong wear resistance of tungsten-nickel-iron alloy, mechanical processing is relatively difficult. Usually, cemented carbide tools or diamond tools are used, and lower cutting speed and larger feed rate are adopted to improve processing efficiency and surface quality. For components with extremely high precision requirements, such as gyro rotors in inertial navigation systems, precision grinding and polishing are also required to make the surface roughness below Ra0.02μm.

Surface treatment is mainly to improve the surface properties of the alloy, such as enhancing corrosion resistance, wear resistance or aesthetics. Common surface treatment methods include electroplating, in which a layer of metal (such as chromium, nickel) is plated on the alloy surface to form a protective film, enhancing corrosion resistance and wear resistance; for alloy parts that need to be welded or bonded, surface sandblasting or chemical etching can be carried out to increase surface roughness and improve bonding strength; in some special applications, the alloy surface will also be coated with a coating, such as high-temperature resistant coating or radiation-proof coating, to expand its application range.

In addition, for some alloy products with special requirements, flaw detection may also be carried out, such as ultrasonic flaw detection, ray flaw detection, etc., to ensure that there are no cracks, pores and other defects inside; for parts that need to be assembled, assembly and debugging will be carried out to ensure their matching accuracy with other parts. The selection of post-processing technology needs to be comprehensively considered according to the specific use of alloy products. Reasonable post-processing can significantly improve the service performance and reliability of tungsten-nickel-iron alloy.

The WeChat public account “China Tungsten Online” updates the prices of various tungstates such as tungstates such as tungstate powder, ammonium tungstate, tungsten products, high-density tungsten alloys, cemented carbides, tungsten concentrates, etc. on a daily basis. At the same time, it provides the most professional WeChat group in the industry for everyone to exchange supply and demand information, and you can exchange information about tungsten powder at any time. Follow “China Tungsten Online” and join the China Tungsten Online WeChat exchange group. Daily tungsten product prices and supply and demand information will be delivered in a timely manner, and real-time communication will be carried out. For more tungsten product market trends, products and information, please follow the “China Tungsten Online” WeChat public account, or visit news.chinatungsten.com to obtain daily updated information.

Contact information: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595

Scan the QR code to follow the “China Tungsten Online” WeChat public account and get real-time updated tungsten, molybdenum and rare earth product market prices and information for free every morning.