The melting point of tungsten-nickel-iron alloy is closely related to its composition. Since tungsten accounts for a high proportion of 80% – 97% in the alloy, and tungsten has a melting point of up to 3422℃, which is one of the elements with the highest melting point among all metals, the melting point of the alloy is mainly dominated by the characteristics of tungsten. However, the addition of nickel and iron will reduce the overall melting point to a certain extent, so that the melting point of tungsten-nickel-iron alloy is usually in the range of 1400 – 1600℃. Specifically, when the content of nickel and iron is high, the melting point of the alloy will decrease slightly; on the contrary, if the content of tungsten is higher, the melting point will be closer to that of pure tungsten. This melting point range is much higher than that of common metals such as steel (about 1538℃) and aluminum (about 660℃), enabling it to maintain a solid structure in high-temperature environments, suitable for scenarios that need to withstand higher temperatures, such as components around rocket engine combustion chambers and high-temperature molds.

Thermal stability refers to the ability of the alloy to maintain performance and structural stability under long-term high-temperature action, and tungsten-nickel-iron alloy performs excellently in this aspect. In high-temperature environments, the internal tungsten particles are not easy to oxidize or sublimate, and although the melting point of the nickel-iron binding phase is lower than that of tungsten, the interface bond formed with tungsten particles at high temperatures is still firm, and it is not easy to soften or separate. Even under cyclic working conditions with repeated temperature changes, the alloy is not easy to crack or deform due to thermal stress. For example, on the surface of hypersonic vehicles in the aerospace field, materials need to withstand high temperatures generated by aerodynamic heating. Tungsten-nickel-iron alloy, relying on good thermal stability, can maintain structural integrity under such extreme conditions, ensuring the normal operation of the equipment. In addition, in some components of nuclear reactors, which are in high-temperature radiation environments for a long time, the thermal stability of the alloy can also ensure that it will not degrade due to high temperature, thus ensuring the safety and reliability of the equipment.

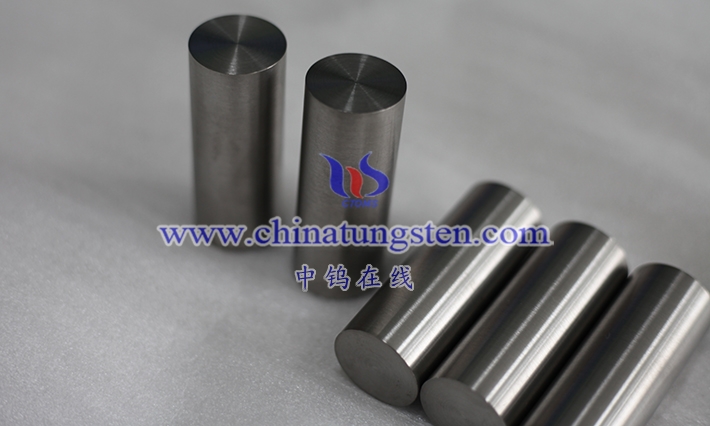

The WeChat public account “China Tungsten Online” updates the prices of various tungstates such as tungstates such as tungstate powder, ammonium tungstate, tungsten products, high-density tungsten alloys, cemented carbides, tungsten concentrates, etc. on a daily basis. At the same time, it provides the most professional WeChat group in the industry for everyone to exchange supply and demand information, and you can exchange information about tungsten powder at any time. Follow “China Tungsten Online” and join the China Tungsten Online WeChat exchange group. Daily tungsten product prices and supply and demand information will be delivered in a timely manner, and real-time communication will be carried out. For more tungsten product market trends, products and information, please follow the “China Tungsten Online” WeChat public account, or visit news.chinatungsten.com to obtain daily updated information.

Contact information: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595

Scan the QR code to follow the “China Tungsten Online” WeChat public account and get real-time updated tungsten, molybdenum and rare earth product market prices and information for free every morning.