The application of tungsten-nickel-iron alloy in 3D printing technology provides innovative solutions for the manufacturing of complex structural components, promoting technological upgrading in multiple fields. 3D printing technology forms parts by layer-by-layer stacking, which can break through the limitations of traditional processing on complex structures. The compatibility between the powder characteristics of tungsten-nickel-iron alloy and 3D printing processes makes it an ideal material for manufacturing high-precision and high-performance components.

In the 3D printing process, tungsten-nickel-iron alloy powder must meet strict requirements on particle size distribution and sphericity to ensure the stability of the printing process and the density of the components. Through technologies such as selective laser melting (SLM) and electron beam melting (EBM), the alloy powder can be melted into a molten state and stacked according to the preset model, finally forming components with complex internal structures. For example, in the medical field, the tungsten-nickel-iron alloy artificial bone scaffold manufactured by 3D printing technology has a porous structure that can better integrate with human bone tissue, and at the same time supports bone load by virtue of the alloy’s mechanical properties; in the aerospace field, complex fuel nozzles, heat dissipation components, etc., have achieved the combination of lightweight and high performance through 3D printed tungsten-nickel-iron alloy, reducing material waste and assembly steps in traditional processing.

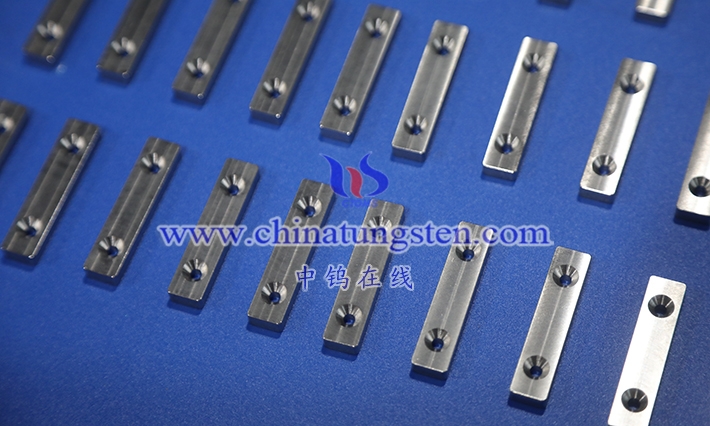

In addition, 3D printing technology can also realize the rapid customized production of tungsten-nickel-iron alloy components, shortening the research and development cycle. For small-batch, multi-variety precision components, such as special sensor housings and micro-mechanical structures, 3D printing can reduce production costs and ensure performance consistency. With the development of 3D printing technology, the application scenarios of tungsten-nickel-iron alloy are constantly expanding, and its advantages in personalized manufacturing and production of functionally integrated components will be further highlighted.

The WeChat public account “China Tungsten Online” updates the prices of various tungstates such as tungstates such as tungstate powder, ammonium tungstate, tungsten products, high-density tungsten alloys, cemented carbides, tungsten concentrates, etc. on a daily basis. At the same time, it provides the most professional WeChat group in the industry for everyone to exchange supply and demand information, and you can exchange information about tungsten powder at any time. Follow “China Tungsten Online” and join the China Tungsten Online WeChat exchange group. Daily tungsten product prices and supply and demand information will be delivered in a timely manner, and real-time communication will be carried out. For more tungsten product market trends, products and information, please follow the “China Tungsten Online” WeChat public account, or visit news.chinatungsten.com to obtain daily updated information.

Contact information: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595

Scan the QR code to follow the “China Tungsten Online” WeChat public account and get real-time updated tungsten, molybdenum and rare earth product market prices and information for free every morning.