Table of contents

Chapter 1 Basic Knowledge of Tungsten-Nickel-Iron Alloy

1.1 Definition of Tungsten-Nickel-Iron Alloy

1.2 Composition of Tungsten-Nickel-Iron Alloy

1.2.1 Characteristics and Functions of Tungsten

1.2.2 Characteristics and Functions of Nickel

1.2.3 Characteristics and Functions of Iron

1.3 Historical Background and Development of Tungsten-Nickel-Iron Alloy

1.3.1 Discovery of Tungsten-Nickel-Iron Alloy

1.3.2 Early Applications and Technological Advances

Chapter 2 Physical and Chemical Properties of Tungsten-Nickel-Iron Alloy

2.1 Density and Mechanical Properties of Tungsten-Nickel-Iron Alloy

2.1.1 High-Density Characteristics

2.1.2 Tensile Strength and Toughness

2.1.3 Hardness and Wear Resistance

2.2 Thermal Properties of Tungsten-Nickel-Iron Alloy

2.2.1 Melting Point and Thermal Stability

2.2.2 Thermal Expansion Coefficient

2.2.3 Thermal Conductivity

2.3 Chemical Stability of Tungsten-Nickel-Iron Alloy

2.3.1 Corrosion Resistance

2.3.2 Antioxidant Properties

2.3.3 Chemical Reactions with Other Materials

2.4 Electromagnetic and Other Special Properties of Tungsten-Nickel-Iron Alloy

2.4.1 Magnetic Properties

2.4.2 Conductivity

2.4.3 Resistivity

2.4.4 Radiation Resistance

2.5 CTIA GROUP LTD Tungsten-Nickel-Iron Alloy MSDS

Chapter 3 Preparation and Processing of Tungsten-Nickel-Iron Alloy

3.1 Raw Material Selection and Pretreatment

3.1.1 Purity Requirements for Tungsten, Nickel and Iron

3.1.2 Raw Material Pretreatment Process

3.2 Preparation Method of Tungsten-Nickel-Iron Alloy

3.2.1 Powder Metallurgy

3.2.2 Liquid Phase Sintering Technology

3.2.3 Additive Manufacturing (3D Printing) Technology

3.2.4 Other Preparation Techniques

3.3 Processing Technology of Tungsten-Nickel-Iron Alloy

3.3.1 Machining

3.3.2 Heat Treatment Technology

3.3.3 Surface Treatment and Coating Technology

Chapter 4 Quality Control and Inspection of Tungsten-Nickel-Iron Alloy

4.1 Composition Analysis of Tungsten-Nickel-Iron Alloy

4.1.1 Chemical Composition Detection Method

4.1.2 Microstructure Analysis

4.2 Performance Test of Tungsten-Nickel-Iron Alloy

4.2.1 Mechanical Properties Test

4.2.2 Thermal Performance Test

4.2.3 Electrical Performance Test

4.2.4 Magnetic Performance Test

4.3 Quality Certification and Standards

4.3.1 Chinese National Standard for Tungsten-Nickel-Iron Alloy

4.3.2 International Standards for Tungsten-Nickel-Iron Alloy

4.3.3 Tungsten-Nickel-Iron Alloy Standards in Europe, America, Japan, South Korea and Other Countries Around the World

Chapter 5 Application Fields of Tungsten-Nickel-Iron Alloy

5.1 Application of Tungsten-Nickel-Iron Alloy in the Aerospace Industry

5.1.1 Balancing Materials

5.1.2 High Temperature Resistant Parts

5.2 Defense and Military

5.2.1 Armor-Piercing Materials

5.2.2 Protective Armor

5.3 Application of Tungsten-Nickel-Iron Alloy in Medical Field

5.3.1 CT/MRI Equipment Shielding Components

5.3.2 Collimators for Radiotherapy Equipment

5.3.3 Precision Medical Devices

5.3.4 Surgical Robot Joint Counterweights

5.3.5 Micro-Weights for Interventional Therapy

5.4 Application of Tungsten-Nickel-Iron Alloy in Precision Instruments

5.4.1 Precision Instrument Counterweights

5.4.2 Lithography Platform Balance Block

5.4.3 High-Speed Machine Tool Spindle Damping Block

5.4.4 Precision Optical Platform Vibration Reduction Components

5.5 Other Applications of Tungsten-Nickel-Iron Alloy

5.5.1 Application of 3D Printing Technology

5.5.2 Potential in the Energy Sector

5.5.3 Golf Club Weights

5.5.4 Racing Engine Balancing Kit

Chapter 6 Advantages and Disadvantages of Tungsten-Nickel-Iron Alloy

6.1 Analysis of the Advantages of Tungsten-Nickel-Iron Alloy

6.1.1 High Density and Strength

6.1.2 Processing Performance

6.2 Limitations of Tungsten-Nickel-Iron Alloy

6.2.1 Cost and Resource Constraints

6.2.2 Environmental and Health Impacts

6.3 Comparison of Tungsten-Nickel-Iron Alloy and Other Materials

6.3.1 Comparison with Tungsten-Nickel-Copper Alloy

6.3.2 Comparison with Lead-Based Alloys

6.3.3 Comparison with Other High-Density Materials

Chapter 7 Environmental Impact of Tungsten-Nickel-Iron Alloy Production and Use

7.1 Environmental Impact During Production

7.1.1 Resource Extraction and Energy Consumption

7.1.2 Waste and Emissions

7.2 Green Manufacturing Technology

7.2.1 Environmentally Friendly Preparation Method

7.2.2 Energy-Saving Technologies

7.3 Recycling and Reuse

7.3.1 Alloy Recovery Technology

7.3.2 Roles in the Circular Economy

Chapter 8 Frequently Asked Questions and Answers

8.1 Common Misunderstandings about Tungsten-Nickel-Iron Alloy

8.2 Common Problems in Technology and Application

8.3 Expert Advice and Solutions

Appendix:

Glossary of Tungsten-Nickel-Iron Alloy Terms

References

Chapter 1 Basic Knowledge of Tungsten-Nickel-Iron Alloy

1.1 Definition of Tungsten Nickel Iron Alloy

Tungsten Nickel Iron Alloy is a high-density alloy material with tungsten as the main component and nickel and iron as the binder phase. It is usually classified as a high-density alloy. This alloy is widely used in aerospace, military, medical, nuclear industry and civilian fields due to its excellent physical and chemical properties. The definition of tungsten nickel iron alloy comes from its main constituent elements and their unique combination of properties: tungsten provides high density and high strength, and nickel and iron as binders enhance the toughness and machinability of the alloy.

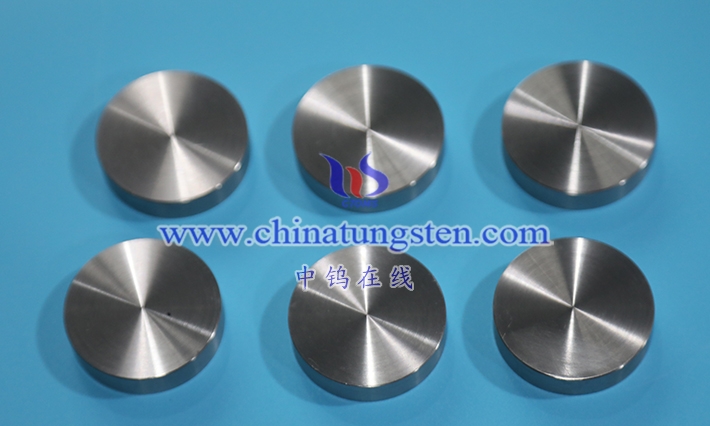

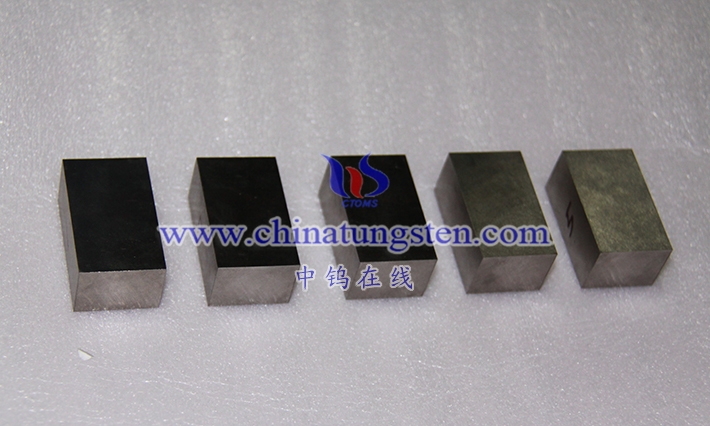

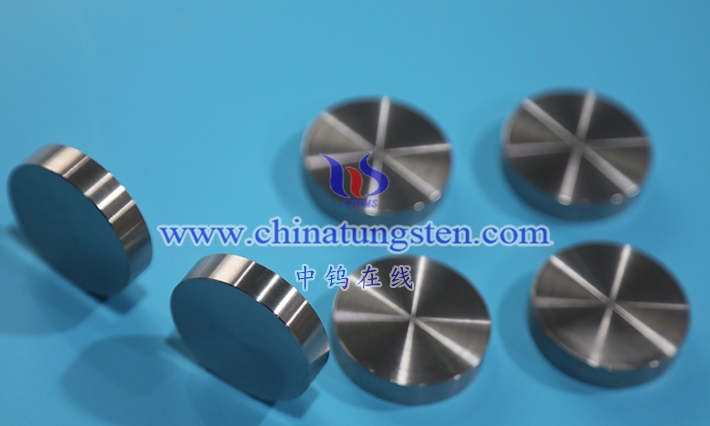

Tungsten -nickel-iron alloy is usually between 16.5-18.75 g/cm³, which is close to the density of precious metals such as gold or platinum , so it is often used as a substitute material. Its main characteristics include high density, high temperature resistance, corrosion resistance and good machinability. Compared with other high-density materials, tungsten-nickel-iron alloy has a higher cost-effectiveness, especially in application scenarios that require high weight to be concentrated in a small volume, such as counterweights, radiation shielding materials and military armor-piercing projectiles.

Tungsten -nickel-iron alloy is usually completed through powder metallurgy process, which involves mixing high-purity tungsten powder, nickel powder and iron powder in a specific proportion, pressing and forming, and sintering at high temperature to form a dense alloy structure. During the sintering process, nickel and iron form a liquid phase, which promotes the bonding of tungsten particles, thus giving the alloy excellent mechanical properties. The composition ratio of tungsten -nickel-iron alloy can be adjusted according to specific uses, such as increasing the proportion of nickel to improve toughness, or adjusting the iron content to optimize cost.

READ MORE:What Is Tungsten Nickel Iron Alloy

===================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

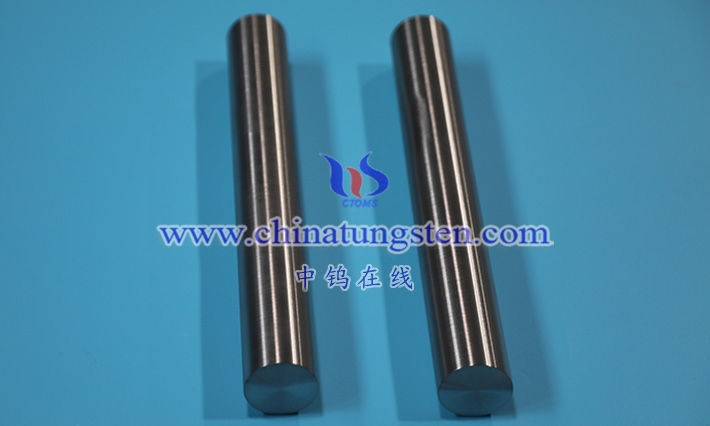

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595