The role of tungsten electrode in argon arc welding is very critical, mainly reflected in the following aspects:

Stabilizing the arc

As a non-consumable electrode, tungsten electrodes are able to maintain their shape and properties during welding, providing a stable and continuous arc. A stable arc is the basis for high-quality welds, ensuring that heat is transferred evenly and welds are well formed.

Conduct current

Tungsten electrodes are responsible for conducting electrical current from the welding power source to the welding area. Tungsten’s excellent conductivity ensures that current passes smoothly, forming a strong arc.

Provides a high-temperature heat source

The arc temperature generated by the tungsten electrode is extremely high, which is enough to melt the metal of the workpiece, form a melt pool, and achieve welding. The tungsten electrode itself is not ablated or melted by the arc due to its high melting point, ensuring a continuous high-temperature heat source.

Reduce electrode consumption and contamination

The tungsten electrode is not involved in melting, so it does not consume or incorporate into the weld, reducing the generation of impurities during the welding process. At the same time, the tungsten electrode is resistant to high temperature and oxidation to avoid premature damage to the electrode part.

Control arc shape

Through the end shape (sharp or spherical) and material properties of the tungsten electrode, the concentration and morphology of the arc can be controlled, thereby affecting the weld width and heat input to adapt to different welding requirements.

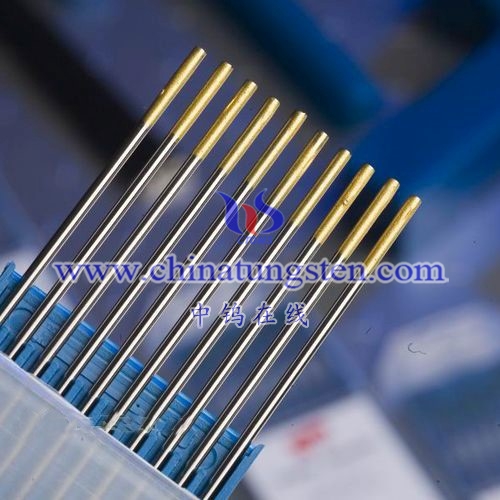

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595