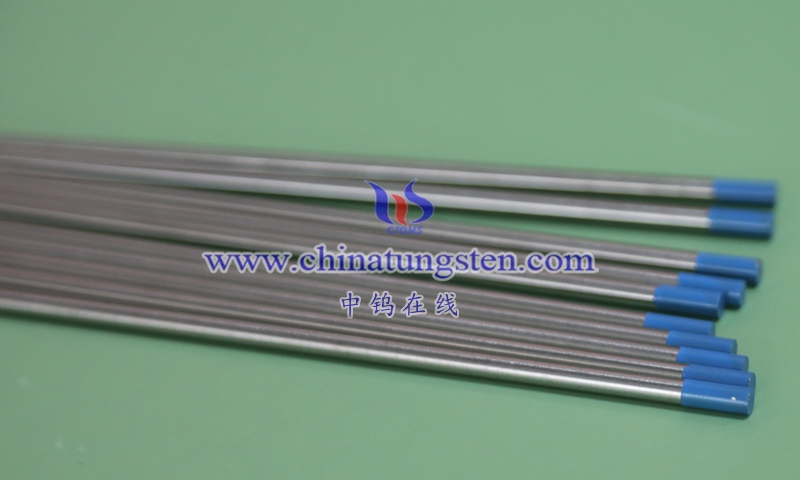

Lanthanum tungsten electrode is a non-radioactive tungsten electrode doped with a certain proportion of lanthanum oxide (La₂O₃) in a tungsten (W) matrix, which is widely used in argon arc welding (TIG welding) processes, especially in welding situations that require both arc initiation performance, arc stability and environmental protection. Its appearance is usually marked in black or gold, representing different concentrations of lanthanum oxide doping ratios (such as 1.0%, 1.5%, 2.0%, etc.).

1.The composition and principle of lanthanum tungsten electrode

Lanthanum tungsten electrodes generally contain about 1%~2% lanthanum oxide, which is doped with the rare earth element lanthanum, so that the electrode has a stronger electron emission ability. Compared with traditional thorium tungsten electrodes, it does not contain radioactive materials, but its arc initiation performance and arc stability can reach or even exceed the level of thorium tungsten.

During the welding process, lanthanum helps the tungsten electrode surface to release electrons stably, making the arc more concentrated and smooth, especially suitable for low-current or automated welding processes.

2.The main characteristics of lanthanum tungsten electrode

Excellent arcing performance

Easy to ignite arc and fast and stable arcing even under low current conditions.

Strong arc stability

During the welding process, the arc fluctuation is small and the heat is concentrated, which improves the welding consistency and weld quality.

Long life and ablation resistance

Lanthanum tungsten electrode has good thermal stability at high temperatures, is not easy to ablation, slow wear, and can extend the service life.

Non-radioactive is safer

Environmentally friendly products that replace thorium tungsten electrodes, have no radioactive contamination, and are suitable for working environments with high safety requirements.

Adaptable

It is suitable for both DC and AC welding (AC), and has a wide range of applications, including carbon steel, stainless steel, aluminum alloy, copper alloy, etc.

3.Typical application scenarios

Automated welding vs. robotic welding

Precision parts, thin plate welding

Industries such as aerospace, electronics manufacturing, and food machinery require high welding quality and cleanliness

TIG welding of stainless steel, carbon steel, aluminum alloy and other metal materials

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595