The causes of tungsten electrodes ablation mainly include the following aspects:

Excessive Current

When the welding current exceeds the bearing capacity of the tungsten electrode, the electrode head will rapidly ablate due to high temperature, resulting in evaporation and deformation of the electrode surface material.

The Arc Is Unstable

Arc runout, intermittent, or offset will cause the electrode head to overheat locally, forming uneven ablation and seriously affecting the welding quality.

Insufficient Or Improper Flow of Shielding Gas

Insufficient flow of shielding gas (usually argon) or incorrect airflow direction can expose the electrode head to air, leading to increased oxidation and ablation.

Electrode Head Contamination

The end is stained with oil, welding slag or other impurities, which can easily cause local overheating and arc abnormalities, promoting ablation.

Improper Sharpening of Electrodes

Improper tip angles or rough surfaces can lead to uneven arc distribution, creating hot spots and increasing the rate of ablation.

The High-frequency Arc Starting Equipment Is Abnormal

Faulty or improper settings of high-frequency arc initiators can lead to difficulty or instability in arc initiation, promoting electrode ablation.

Welding Environmental Factors

If the humidity is too high, the gas purity is low, or impurities are contained, the oxidation and ablation of the electrode will be aggravated.

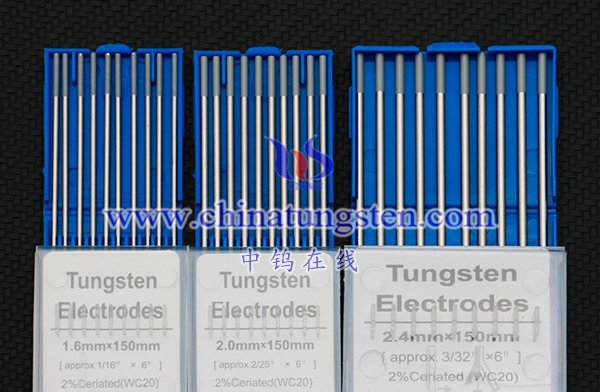

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595