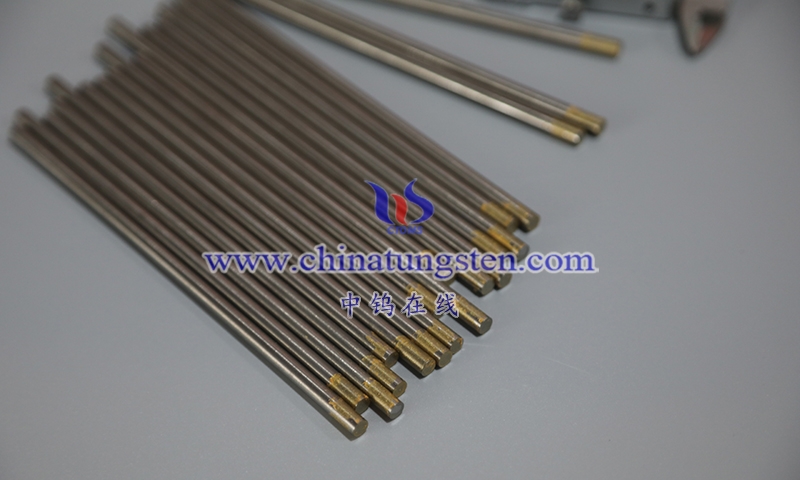

Argon arc welding tungsten electrodes are typically protected with a single inert gas, mainly high-purity argon, but in some special applications, dual-gas protection is indeed employed. The details are as follows:

Single-gas Protection (argon)

In most argon arc welding (TIG welding) processes, pure argon gas is used as a shielding gas to cover the welding area and around the tungsten electrode, preventing oxygen, nitrogen, and moisture from the air from coming into contact with the weld and electrode, thereby avoiding oxidation and contamination. This method is simple and works well, and is suitable for most metal welding.

Dual Gas Protection

The so-called dual gas protection refers to the use of two gases to protect the welding area at the same time, such as the inner layer of argon gas to protect the weld and electrode, and the outer layer to use auxiliary gases (such as helium, nitrogen or hydrogen mixture) for secondary protection or to improve welding performance. Dual gas protection is mainly used in:

Improved arc stability and heat input: Helium, as an auxiliary gas, can increase arc temperature, enhancing weld depth and speed.

Improved weld quality and appearance: The gas mixture reduces spatter and improves weld formation.

Special material welding: When welding some stainless steels, aluminum alloys and special alloys, double gas protection is used to prevent porosity and cracks.

Prevent hydrogen embrittlement or nitriding: Appropriately adjust the composition of the protective gas to control the hydrogen or nitrogen content.

Protection of Tungsten Electrodes

Dual-gas protection is not specifically mandatory for tungsten electrode protection, but the auxiliary gas flow and composition may indirectly affect the arc shape and lifetime of the electrode terminal.

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595