The resistance of the tungsten electrode will affect the performance of the welding arc, which is reflected in the following aspects:

Arc Stability

If the resistance of the tungsten electrode is too high, it will cause difficulty in arc starting, large current fluctuations, and the arc is easy to jump or extinguish, affecting the stability of the welding process.

Heat Distribution

Electrodes with higher resistance may generate local overheating, leading to increased electrode ablation and deterioration of electrode shape, which in turn affects arc concentration and heat transfer efficiency.

Arc Length Control

Resistance changes can affect the matching of current and voltage, resulting in uncontrollable arc length and uneven weld forming.

Arc Performance

The lower electrode resistance is conducive to fast and smooth arcing, improving welding efficiency and quality.

Therefore, maintaining the good conductivity of the tungsten electrode and properly controlling the resistance value are important factors to ensure the stability of the welding arc and improve the welding quality.

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

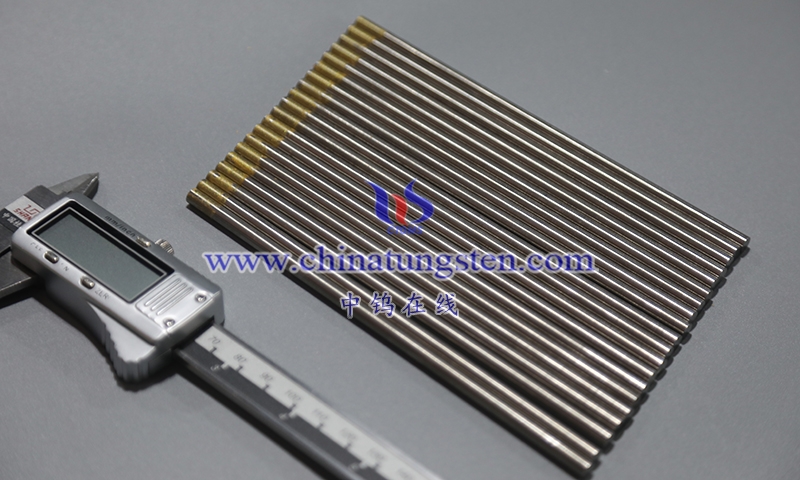

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595