High melting point is indeed one of the important advantages of tungsten electrode, but “the higher the melting point, the better” is not the only criterion for evaluating the performance of tungsten electrode, and the specific situation needs to comprehensively consider the following aspects:

The Importance of Melting Point

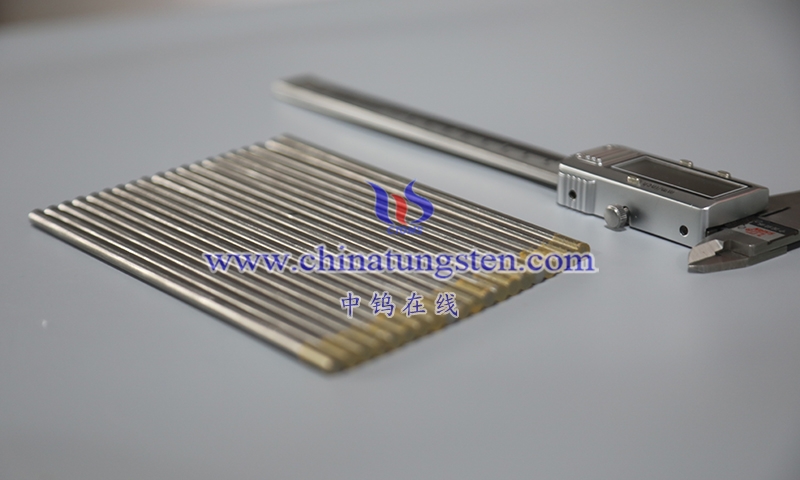

The melting point of tungsten electrodes is extremely high (about 3410°C), making them less likely to melt or deform in high-temperature arcs, ensuring that the electrode serves as the core function of non-melting electrodes and provides a stable arc heat source.

The Role of Alloying Elements

In order to improve arcing performance, electrode life, and ablation resistance, alloying elements such as thorium, cerium, lanthanum, and zirconium are usually added to tungsten electrodes. These elements will slightly reduce the melting point of pure tungsten, but significantly improve the overall performance of the electrode, such as reduced arc starting voltage, more stable arcing, and longer service life.

Comprehensive Performance First

In fact, high-quality tungsten electrodes not only look at the melting point, but also pay attention to arc initiation performance, electrode wear resistance, arc stability and environmental safety (such as reducing radioactive elements). Alloy tungsten electrodes tend to better meet actual welding needs.

Use Scenario Matching

Different welding materials and processes have different electrode performance requirements, and choosing the right tungsten electrode type and composition is more important than simply pursuing the melting point.

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595