The arc concentration of tungsten electrode is mainly related to the following aspects:

Electrode Tip Shape

The sharpening angle of the tungsten electrode head has the greatest impact on the arc concentration. Sharp ends (such as around 15°) produce a more concentrated arc and are suitable for thin plates or fine welding; Blunt ends (such as 60° and above) arcs are more dispersed, suitable for thick plates and high current welding.

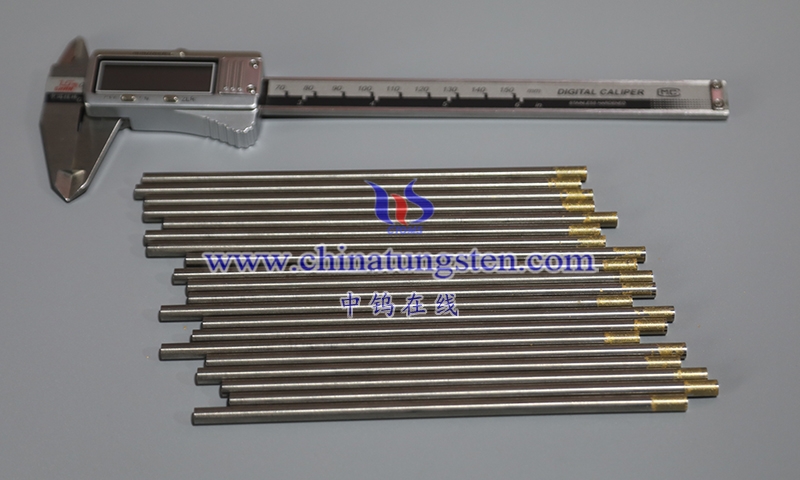

Electrode Material and Alloy Composition

Different types of tungsten electrodes (pure tungsten, thorium tungsten, lanthanum tungsten, etc.) have different arc stability and concentration due to different material properties. Alloy tungsten electrodes usually arc more stable and focused.

The Size of the Welding Current

Higher welding currents will cause arcs to diffuse and reduce concentration; At lower currents, the arc is slenderer and the concentration is higher.

Types And Flow Rates Of Protective Gases

The purity and flow rate of the shielding gas affect the arc shape. Proper airflow stabilizes the arc and concentrates it; Too much or too little airflow can cause the arc to disperse or become unstable.

Electrode Position And Alignment

If the tungsten electrode deviates from the center of the welding torch or the spacing between it and the workpiece is improper, it will affect the arc direction and concentration, resulting in uneven welding quality.

Electrode Polarity

The positive and negative polarity of the electrode also affects the arc morphology, and the arc concentration is usually better under DC negative polarity (DCEN).

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595