The working life of a tungsten electrode is a comprehensive indicator that usually depends on its ability to maintain good arc initiation performance, arc stability, and end morphology under actual welding conditions, or the duration or number of uses. Specifically, it can be quantified and evaluated in the following ways:

1.Hour-based Life

One of the most common ways to quantify. Record the continuous use of a single tungsten electrode under normal welding conditions until the end of life occurs when any of the following phenomena occur:

Difficulty or failure to start arcing

Arc divergence or instability

The electrode tip is severely ablated or deformed

The quality of the weld is significantly reduced

For example, a model of lanthanum tungsten electrode has arc instability after 12 hours of cumulative use at 100A, which can be recorded as “life = 12 hours”.

2.Cycle-based Life

For automated or spot welding processes, electrode life can be expressed in terms of the number of successful arc starts.

The total number of times each electrode can stabilize arcing under the same working conditions (usually more than 1,000 times) is recorded.

It is suitable for evaluating electrode life in low-current welding and continuous automatic welding.

For example, a cerium-tungsten electrode can stabilize the arcing of 1800 times, and the life is “1800 arc starts”.

3.Performance Degradation Point

“Acceptable welding quality” is used as the criterion for determining electrode life, and the following indicators are paid attention to changes during the service life:

Whether the weld is formed evenly

Whether the arc is stable

Whether tungsten inclusions occur

Whether the electrode needs to be reground frequently

When a certain indicator drops significantly, the electrode is considered to have reached the end of its life.

4.Tip Wear Evaluation

Service life is assessed by measuring the ablation length, mass loss, or degree of deformation of the tungsten electrodes:

Weigh the mass loss after each weld with a balance (mg)

Measure tip radius changes with a microscope

When a certain wear threshold is reached, the end of life is considered

5.Comparative Evaluation Method (relative Lifetime)

Comparing the life of tungsten electrodes of different materials or brands under the same welding conditions is a common evaluation method for enterprises.

For example:

The thorium tungsten electrode life is the benchmark

Lanthanum tungsten is 80% of it

Rare earth tungsten is 120% of it

This allows for the establishment of a “relative life index”.

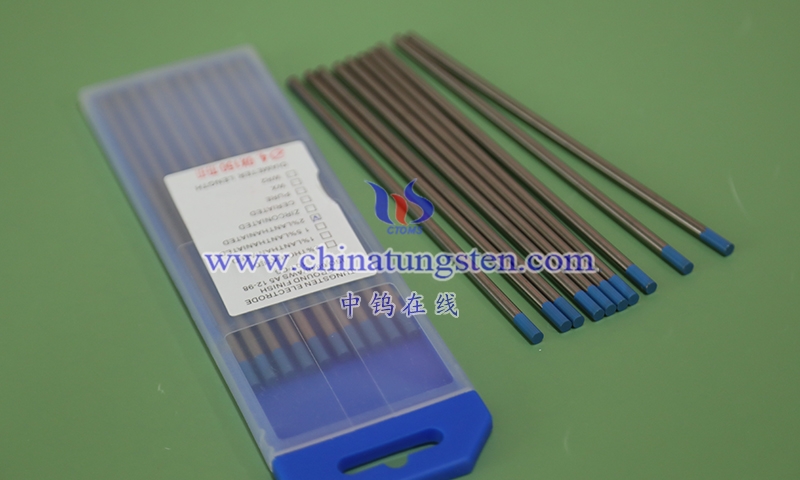

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595