The material of the tungsten electrode has a significant impact on the spatter during the welding process. Tungsten electrodes of different materials have different electron emission properties, arc stability, and high-temperature resistance, all of which affect the stability of the arc and the control of the melt pool, thereby affecting the amount of spatter.

Here are the effects of common tungsten electrode materials on welding spatter:

- Pure Tungsten Electrode (WP)

No doped elements, poor electron emission ability;

The arc starts slowly and unstable, and it is easy to produce the phenomenon of “arc skipping”;

The amount of splash is large, and the melt pool control is difficult, and it is generally used when welding aluminum in AC.

- Thorium Tungsten Electrode (WT20)

2% thorium is added to improve the thermionic emission capacity;

The arc is concentrated and stable, and there is less spatter;

It is commonly used for DC welding carbon steel, stainless steel, etc.

- Lanthanum Tungsten Electrode(WL15/WL20)

Mixed with 1.5% or 2% lanthanum, the comprehensive performance is good;

Good arc initiation, stable arcing, suitable for a variety of welding modes;

Low spatter for automated or fine welding.

- Cerium Tungsten Electrode (WC20)

Mixed with 2% cerium, suitable for low-current welding;

The arc is soft, easy to control, and there is little splash;

It is suitable for precision welding of thin plates or small pieces.

- Zirconium Tungsten Electrode (WZ8)

Mixed with 0.8% zirconium, suitable for AC welding aluminum and magnesium alloys;

It has good anti-pollution and self-sphering ability;

Medium splash, but more stable than pure tungsten.

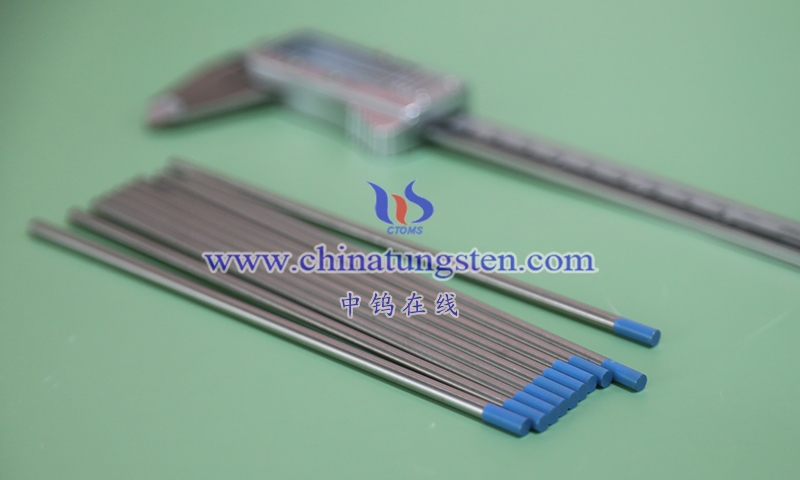

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595