The vibration of the tungsten electrode during welding can have obvious adverse effects, especially in high-precision welding or automated welding. Here are the specific effects that vibration can bring:

- The Arc Is Unstable

When the electrode vibrates, the arc length will fluctuate continuously, resulting in arc instability;

Arc drift and divergence, affecting the concentration of the melt pool and heat input control;

The weld appearance deteriorates and the penetration depth is uneven.

- Increased Splashing

Arc jitter will make the molten droplets unable to transition stably and increase the amount of splash.

Splashing particles pollute the surface of the workpiece, increasing the difficulty of subsequent cleaning;

It is particularly disadvantageous in precision welding situations, such as thin plates, electronic components, etc.

- Electrode Ablation Intensifies

Vibration can cause frequent arc shifts and impact on the electrode tip;

It is easy to cause local overheating and accelerated tip burning;

The electrode shape is prone to blunt or eccentricity, shortening the service life.

- Reduced Weld Quality

The weld is of different width and width, and the edge of the weld is rough;

It is easy to have defects such as non-fusion, slag inclusion or porosity;

The welding accuracy decreases, especially affecting the welding effect of automatic welding or robot welding.

- May Cause Electrode Cracking

Long-term mechanical vibration and heating stress can easily induce faTIGue cracks;

This is especially true when the tungsten electrode is of poor quality or improper clamping.

- Affect The Automatic Control Of Welding

In automatic welding, tungsten electrode vibration can interfere with the arc tracking system;

Resulting in position deviation, trajectory drift, and affecting the consistency of the weld;

Butt welding robots or precision welding platforms are a major hidden danger.

Prevention Recommendations:

Check whether the electrode chuck is firm and not loose;

The welding torch body should be installed steadily to avoid mechanical resonance;

The welding platform should be shock-proof and anti-resonance as much as possible;

Use electrode clamping system with good seismic performance;

Avoid setting unnecessary motion acceleration or frequent start-stop settings in automatic welding.

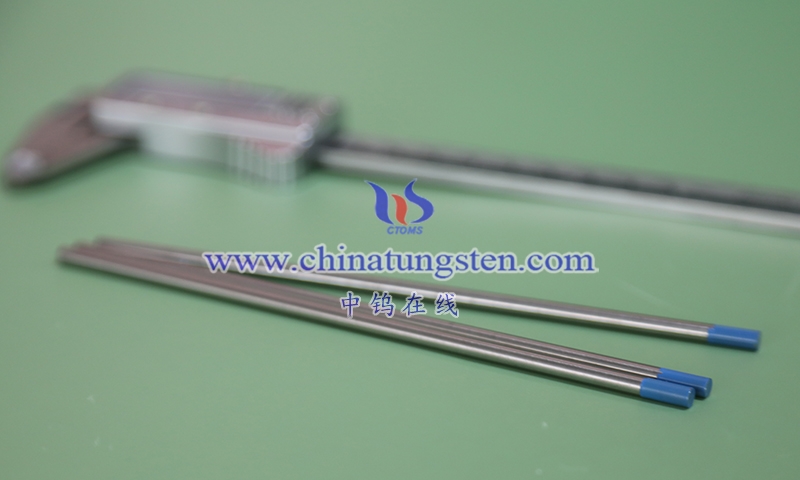

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595