The coefficient of thermal expansion of tungsten electrode is a key parameter, especially in the process of high-temperature welding, it has an important impact on the structural stability, crack resistance, arc stability and welding quality of the electrode.

Here’s a specific explanation of the critical coefficient of thermal expansion:

- Definition Of Coefficient Of Thermal Expansion

The coefficient of thermal expansion (linear expansion coefficient) of tungsten is approximately:

4.5 × 10⁻⁶ /K(25~1000°C)

Compared with most metals (such as steel is about 1113 × 10⁻⁶ /K and copper is 1617 × 10⁻⁶/K), tungsten has a very low coefficient of thermal expansion and shows good thermal stability.

- Effect On The Performance Of Tungsten Electrodes

(1) Thermal shock resistance

Low coefficient of thermal expansion → small volume change during heating and cooling;

It can significantly reduce the accumulation of thermal stress and prevent cracks;

Improve the stability of the electrode in multiple arcing starts and stops.

(2) Good dimensional stability

It has strong shape retention ability at high temperature and is not easy to deform.

Ensure the stability of the electrode tip, which is conducive to arc concentration;

It helps to control the penetration depth and width, and the weld quality is more stable.

(3) Reduce the thermal stress difference between the fixture and the fixture

The tungsten electrode has less expansion and is not easy to loosen or fractured due to the difference in thermal expansion.

When combined with ceramic nozzles or copper fixtures, the risk of thermal faTIGue failure is reduced.

(4) It helps to extend the life of the electrode

microcracks or fractures are not easy to occur when the electrode is repeatedly heated;

Maintains a long service life and low maintenance frequency.

- Application Value

The reason why tungsten electrodes are suitable for high-temperature welding (such as argon arc welding and plasma arc welding) is precisely because of its following:

High melting point (about 3410°C);

Low coefficient of thermal expansion;

High thermal conductivity;

Excellent heat resistance and creep resistance.

These properties work synergistically to make tungsten a preferred choice for high-temperature electrode materials.

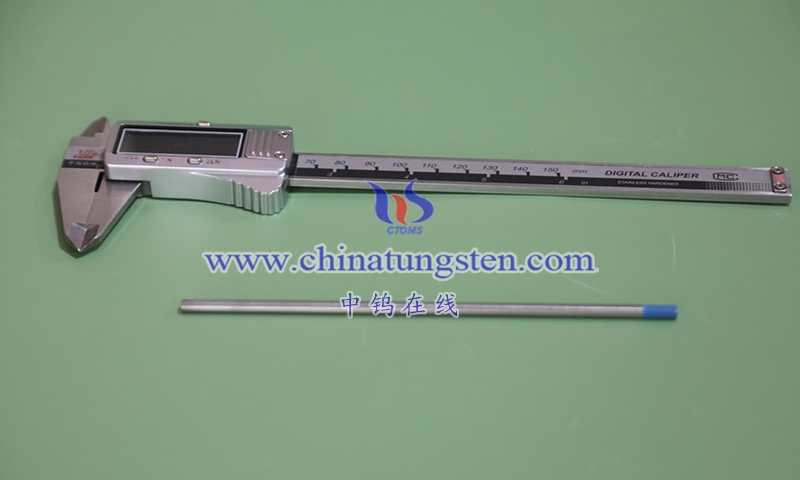

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595