Directory

Chapter 1 Introduction

1.1 Concept and Definition of Pure Tungsten

1.2 The History of the Discovery and Development of Pure Tungsten

1.3 Position and Physical and Chemical Properties of Tungsten in the Periodic Table

1.4 Difference Between Pure Tungsten and Tungsten Alloy

1.5 The Importance of Pure Tungsten Sheets in Modern Industry

Chapter 2 Properties and Theoretical Basis of Tungsten Materials

2.1 Physical Properties of Pure Tungsten Sheets

2.2 Chemical Stability and Corrosion Resistance of Pure Tungsten Sheets

2.3 Thermal Properties of Pure Tungsten Sheets

2.4 Mechanical Properties of Pure Tungsten Sheets

2.5 Electrical Properties of Pure Tungsten Sheets

2.6 Crystal Structure and Microstructure Characteristics of Pure Tungsten Sheets

2.7 Pure Tungsten Sheet MSDS from CTIA GROUP LTD

Chapter 3 Raw Materials and Preparation Process of Pure Tungsten Sheets

3.1 Tungsten Ore Resources and Extraction Process

3.2 Preparation Method of High-Purity Tungsten Powder

3.3 Pressing Molding Technology

3.4 Sintering Process

3.5 Hot and Cold Rolling Technology

3.6 Precision Machining and Surface Treatment

3.7 Difficulties in Machining

3.8 Advanced Manufacturing Technology

3.9 Preparation Technology of Ultra-Thin Pure Tungsten Sheets

3.10 Green and Energy-Saving Preparation Technology

Chapter 4 Types and Specifications of Pure Tungsten Sheets

4.1 Pure Tungsten Sheets Classified According to Purity

4.2 Pure Tungsten Sheets Classified According to Thickness

4.3 Pure Tungsten Sheets Classified According to the Processing State

4.4 Pure Tungsten Sheets Classified According to Their Use

4.5 Special Form of Pure Tungsten Sheet

4.6 Common Dimensions and Tolerance Standards for Pure Tungsten Sheets

Chapter 5 Detection and Quality Control of Pure Tungsten Sheets

5.1 Appearance and Size Detection Method of Pure Tungsten Sheet

5.2 Analysis of Purity and Chemical Composition of Pure Tungsten Sheets

5.3 Mechanical Properties Test of Pure Tungsten Sheet

5.4 Thermal and Electrical Properties of Pure Tungsten Sheets

5.5 Microstructure Analysis of Pure Tungsten Sheets

5.6 Defect Detection of Pure Tungsten Sheets

5.7 Life and Reliability Evaluation of Pure Tungsten Sheets

5.8 Quality Control Process and Standard of Pure Tungsten Sheets

Chapter 6 Application Fields of Pure Tungsten Sheets

6.1 Electronics and Semiconductor Industry

6.2 Lighting Industry

6.3 Aerospace

6.4 Vacuum Devices and Tubes

6.5 Nuclear Energy Industry

6.6 Hot Field Components of High-Temperature Furnaces

6.7 Special Uses

Chapter 7 Standards and Certification of Pure Tungsten Sheets

7.1 Domestic Standards for Pure Tungsten Sheets

7.2 International Standard for Pure Tungsten Sheets

7.3 Chemical Composition and Purity Standards of Pure Tungsten Sheets

7.4 Dimensions and Tolerance Standards for Pure Tungsten Sheets

7.5 Testing and Inspection Standards for Pure Tungsten Sheets

7.6 Environmental and Safety Standards for Pure Tungsten Sheets

Chapter 8 Safety, Environmental Protection and Recycling of Pure Tungsten Sheets

8.1 Safety Precautions for Pure Tungsten Processing and Use

8.2 Protective Measures for Pure Tungsten Dust

8.3 Recycling and Reuse Technology of Waste Pure Tungsten Sheets

8.4 Tungsten Resource Recycling System

8.5 Environmental Impact and Green Development of Tungsten Industry

Chapter 9 Performance Optimization and Alloying of Pure Tungsten Sheets

9.1 Limitations and Improvements of Pure Tungsten Sheets

9.2 Introduction of Tungsten Alloy

9.3 Doping and Modification Techniques

9.4 Characteristics and Applications of Nanoscale Pure Tungsten Sheets

Chapter 10 Market and Future Development of Pure Tungsten Sheets

10.1 Global Pure Tungsten Sheet Industry Pattern and Major Producers

10.2 Market Demand and Price Trend Analysis

10.3 New Pure Tungsten Sheet Preparation and Performance Improvement Technology

10.4 Development Trend of Nanobilization and Compounding

10.5 Potential Applications in New Energy and Quantum Technology

10.6 Sustainable Development Strategy of the Pure Tungsten Sheet Industry

Appendix

- Commonly Used Physicochemical Data Sheets

- Explanation of Tungsten-Related Terms

- References

Chapter 1 Introduction

1.1 Concept and definition of pure tungsten

Pure tungsten, as a highly pure form of metal element, is an integral component in modern materials science and industrial applications. The concept stems from the essential form of the element tungsten, which is tungsten metal with no or only trace impurities. The chemical symbol for tungsten is W, derived from its earlier name “wolfram” and has an atomic number of 74. It is a rare metal that is almost always found in nature as a compound and rarely in a free state. The definition of pure tungsten can be elaborated from multiple dimensions: first, from a chemical point of view, it is a simple form of tungsten element, and the purity is usually required to be more than 99.95% to ensure that its unique physical and chemical properties are not disturbed by impurities. Secondly, from the perspective of physical properties, pure tungsten presents a silvery-gray luster, the texture is hard but relatively brittle at room temperature, and the surface is easy to oxidize to form a thin oxide layer.

In a deeper definition, pure tungsten is considered a transition metal with extremely high melting and boiling points, which makes it excel under extreme conditions. Its crystal structure is mainly a body-centered cube (BCC) structure, which gives it excellent mechanical strength and thermal stability. Pure tungsten has a density of approximately 19.3 g/cm3, which is almost comparable to gold, making it stand out in situations where high-density materials are required. For example, in counterweight or radiation shielding applications, this density characteristic is crucial. Pure tungsten also has a very high hardness, with a hardness of 6.5 to 7.5 on the Mohs scale, which means it is resistant to wear and tear and is not easy to deform, but it also brings difficulties to process because pure tungsten is prone to breakage at low temperatures.

From the perspective of industrial standards, the concept of pure tungsten is often linked to international norms, such as the ASTM B760 standard, which specifies purity requirements in the form of pure tungsten plates, sheets, rods, etc. Normally, the content of impurities such as carbon, oxygen, and nitrogen in pure tungsten needs to be controlled at very low levels, because even trace amounts of impurities can significantly affect its ductility and conductivity. The thermal conductivity of pure tungsten is about 174 W/m·K, and although its conductivity is not as good as that of copper or silver, its stability at high temperatures far exceeds that of these metals. This gives pure tungsten a unique position in the field of electronics and thermal management.

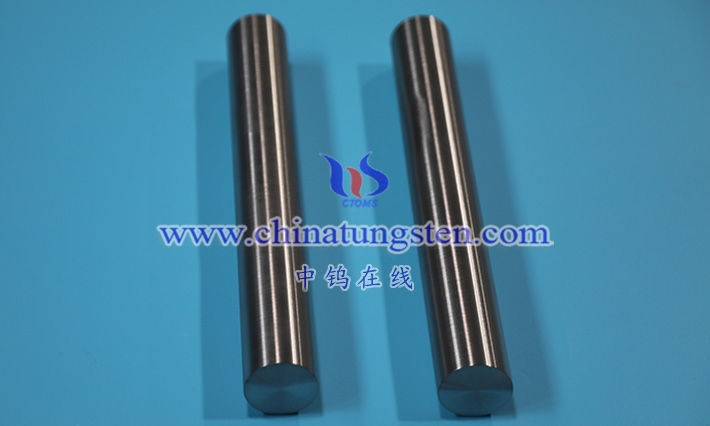

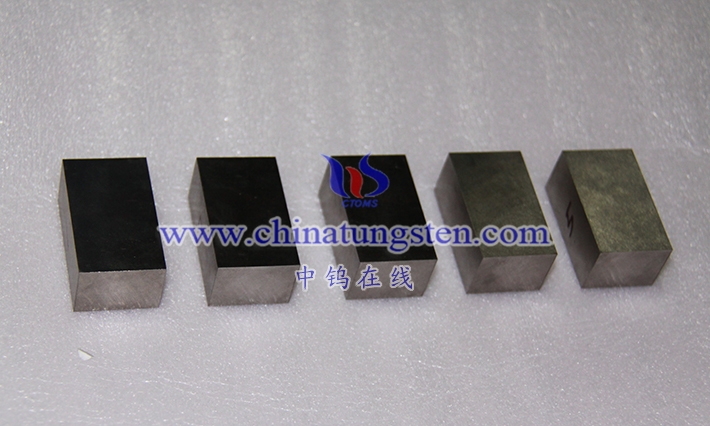

Expanding on the concept of pure tungsten, we can explore its morphological diversity. Pure tungsten can exist in various forms such as powder, bar, wire, sheet, etc. Among them, pure tungsten sheets are the form that this book focuses on, which is a thin sheet material prepared by powder metallurgy process or chemical vapor deposition and other methods, usually ranging from 0.05 mm to several millimeters in thickness. This sheet format allows for easy cutting, bending, and welding, making it suitable for precision manufacturing. The concept of pure tungsten also extends to its isotopic composition: tungsten has five stable isotopes (180W, 182W, 183W, 184W, 186W), which is important in nuclear physics applications.

When defining pure tungsten, one cannot ignore its interaction with the environment. Pure tungsten is highly sensitive to oxygen and forms WO3 oxide, a yellow powder commonly used in pigments or catalysts when heated in air. But by vacuum or inert gas protection, pure tungsten can maintain its metallic luster. The biocompatibility of pure tungsten is also worth mentioning, although it is not a bioessential element, its low toxicity makes it safe to use in medical devices, such as X-ray tube targets.

1.2 The history of the discovery and development of pure tungsten

The history of the discovery and development of pure tungsten is a journey of scientific exploration that spans centuries, filled with milestones in mineralogy, chemistry, and metallurgy. This history not only reveals the process of human cognition of unknown elements, but also reflects the context of the Industrial Revolution and technological progress.

The origin of tungsten dates back to the mid-17th century. At that time, European miners discovered a strange ore in tin mines that “swallowed” tin during tin smelting, leading to reduced output. This ore was called “wolfram” by German miners, which means “wolf’s foam”, because it “eats” tin like a wolf. Similarly, in Sweden it is called “tungsten”, which means “heavy stone”. These early observations established the enigmatic image of tungsten minerals.

The real scientific breakthrough occurred in the 18th century. In 1758, Swedish chemist and mineralogist Axel Fredrik Cronstedt, while studying a mineral called “heavy stone” (now known as suchtenite), discovered that it contained an unknown substance. He named the mineral “tungsten”, but did not isolate the elements. In 1781, another Swedish chemist, Carl Wilhelm Scheele, experimentally extracted a new acid, tungstic acid, from scucanite. Scheller dissolved the ore in nitric acid, obtaining a yellow tungsten precipitate, which marked the first identification of tungsten compounds. However, Scherer did not further isolate the metal tungsten.

The honor of isolating pure tungsten goes to the Spanish chemist and mineralogist Juan José Elhuyar and the brothers Fausto Elhuyar. In 1783, they used charcoal to reduce tungsten acid in Seville, Spain, and successfully obtained metal tungsten powder. This work was independent of Scherer, but was inspired by him. The brothers named the new element “wolfram” and published their findings. This marked the official birth of pure tungsten as an element.

In the 19th century, the application of tungsten began to sprout. In 1816, British chemist Humphry Davy studied the electrochemical properties of tungsten, but the industrial production of pure tungsten still faced challenges. Due to the high melting point of tungsten (3422°C), traditional melting methods are ineffective. It was not until the 1850s that tungsten began to be used in steel alloys. In 1858, the first tungsten-containing steels were patented, leading to the emergence of self-hardening steels in 1868. These steels maintain their hardness at high temperatures, revolutionizing tool manufacturing.

At the beginning of the 20th century, a breakthrough was made in the purification technology of pure tungsten. In 1903, William M. William D. Coolidge invented the preparation method of ductile tungsten filament. Through powder metallurgy and hydrogen reduction processes, he obtained high-purity tungsten filament for use in incandescent light bulbs. This invention significantly extended the life of the bulb and revolutionized the lighting industry. In 1913, Kulich’s tungsten target was used in X-ray tubes, further expanding medical applications.

The two world wars accelerated the development of tungsten. Tungsten is considered a strategic metal and is used in the military industry, such as armor-piercing shells and high-speed steel tools. During World War II, the supply of tungsten ore was tight, leading to the development of alternatives. After the war, tungsten alloys such as tungsten cobalt carbide (cemented carbide) emerged, developed by the German company Krupp in the 1920s for cutting tools.

In the 21st century, the development of pure tungsten focuses on nanotechnology and high-purity preparation. Chemical vapor deposition (CVD) and physical vapor deposition (PVD) techniques allow the preparation of ultra-thin pure tungsten wafers for use in semiconductors and solar cells. In recent years, with the rise of nuclear fusion research, pure tungsten has been selected as the plasma-facing material for the International Thermonuclear Experimental Reactor (ITER) due to its ability to withstand extreme heat and radiation.

The history of pure tungsten also includes environmental and economic aspects. Tungsten ore is mainly mined in China, Russia, and Vietnam, and the global supply chain affects its price. The development of recycling technologies has reduced environmental impact, such as extracting tungsten from used carbide.

1.3 Position and physical and chemical properties of tungsten in the periodic table

Tungsten’s position in the periodic table determines its unique physical and chemical properties, making it a standout in materials science. Tungsten is located in the sixth period of the periodic table, group VIb (group VIb), and belongs to transition metals. It has an atomic number of 74 and an atomic mass of approximately 183.84 u. Tungsten is congeners to chromium and molybdenum, and these elements share a similar electronic configuration: Tungsten’s electronic configuration is [Xe] 4f¹⁴ 5d⁴ 6s², which gives it a variable oxidation state, from -2 to +6, most commonly +6.

In the periodic table, the position of tungsten reflects its properties as a heavy transition metal. It is located in the D region, where electrons fill the D orbital, resulting in high density and high melting point. Tungsten has an atomic radius of about 139 pm and a covalent radius of 162 pm, which makes its crystals compact.

In terms of physical properties, tungsten is known for its extreme values. The melting point is 3422°C, the highest of all metals, and the boiling point is 5555°C. This makes tungsten stable in high-temperature environments, such as rocket nozzles or furnace linings. The density is 19.25 g/cm³, which is almost two and a half times that of iron, which is crucial in applications that require compact weight, such as vibration suppressors.

Tungsten has a high hardness, with a Vickers hardness of about 3430 MPa, but pure tungsten is brittle at room temperature and is prone to breakage along grain boundaries. Ductility can be improved by machining. Tungsten has a low coefficient of thermal expansion (4.5 × 10⁻⁶/K), a thermal conductivity of 174 W/m·K, and an electrical conductivity of 1.82 × 10⁷ S/m. These properties make them suitable for electronic devices.

Chemically, tungsten is highly resistant to corrosion. It does not react with most acids, but can be corroded by aqua regia or hydrofluoric acid. In air, tungsten oxidizes slowly to form WO₃, but needs to be protected at high temperatures. Tungsten forms a variety of compounds, such as tungstate (WO₄²⁻), which are used in catalysts. Tungsten has a variety of oxidation states, ranging from +6 in WO₃ to +4 in WC.

The magnetic properties of tungsten are paramagnet, and the Curie point is high. It has an elastic modulus of about 411 GPa and a tensile strength of up to 1510 MPa (in filament form). The heat capacity was 24.27 J/mol· K, the vapor pressure is low at high temperatures.

At the quantum level, the d electrons of tungsten are involved in bonding, resulting in high strength. The isotopes of tungsten include five stable isotopes for geological dating.

1.4 Difference between pure tungsten and tungsten alloy

Pure tungsten is distinguished from tungsten alloys by composition, properties, and applications, and although both are based on tungsten elements, the alloy significantly alters the limitations of pure tungsten by adding other metals.

Pure tungsten is more than 99.95% tungsten element, which is highly brittle and difficult to process. At room temperature, it is prone to chipping, with high Mohs hardness but poor ductility. The advantages of pure tungsten are pure properties, such as the highest melting point and density, but the disadvantages are low temperature brittleness and oxidation sensitivity.

Tungsten alloys are added with elements such as nickel, iron, copper or cobalt, usually more than 90% of tungsten. Common alloys include tungsten-nickel-iron (W-Ni-Fe) and tungsten-nickel-copper (W-Ni-Cu). These alloys improve ductility, making them easier to machine. The brittleness of alloys is reduced, and the strength and toughness are enhanced, such as the tensile strength of W-Ni-Fe alloy is higher than that of pure tungsten.

In terms of physical properties, the density of pure tungsten is 19.3 g/cm³, and the alloy is slightly lower but still high. At the melting point, the alloy is lower than pure tungsten, but still resistant to high temperatures. The thermal and electrical conductivity of the alloy can be adjusted by additives such as copper alloys to improve electrical conductivity.

Chemically, pure tungsten is corrosion-resistant, but the alloy may introduce new reactions, such as copper-containing alloys that are prone to oxidation. The crystal structure of the alloy changes from pure tungsten BCC to a composite phase, which increases the hardness.

Application difference: Pure tungsten is used in situations where purity is required, such as filament or target; Alloys are used in the military industry, medical care, such as radiation shielding or counterweights.

In terms of processing, pure tungsten requires powder metallurgy, and the alloy is easier to forge. In terms of cost, pure tungsten is more expensive due to the difficulty of purification.

1.5 The importance of pure tungsten sheets in modern industry

As an advanced metal material with high melting point, high density and high thermal conductivity, pure tungsten sheet occupies an irreplaceable position in the modern industrial system. From aerospace, nuclear energy, electronics, machinery manufacturing to emerging high-tech fields, pure tungsten sheets play a key role. Its importance is not only reflected in the material performance, but also in the supporting role of industrial development and high-end manufacturing technology.

The core material of the high-temperature industry

Tungsten has a melting point of up to 3422°C, which is one of the highest among all metal materials. Pure tungsten sheets have thus become an indispensable material for high-temperature industries. Modern high-temperature industries, such as high-temperature furnaces, vacuum furnaces, tungsten wire evaporation sources, tungsten crucibles, and high-temperature electrodes, rely on the thermal stability and high-temperature strength of pure tungsten sheets. Tungsten wafers can maintain good grain structure and mechanical properties at high temperatures, ensuring long-term stable operation of critical equipment in extreme environments.

In the aerospace field, pure tungsten sheets are used in core parts such as rocket nozzles, spacecraft high-temperature protection components and missile engine nozzles, which can withstand transient extremely high temperatures and strong thermal shock. In addition, in the metallurgical industry, pure tungsten sheets are widely used in high-temperature crucibles and melting plants to ensure high-temperature stability and material purity in the metal melting process.

Nuclear energy and strategic materials in high-radiation environments

Tungsten’s high density (19.3 g/cm³) and excellent radiation resistance make it widely used in the nuclear energy industry. Pure tungsten sheets are commonly used in neutron shielding, nuclear reactor structural parts, and protective materials for radioactive equipment. The high-density feature can effectively block high-energy neutrons and γ rays, providing security for nuclear energy facilities and scientific research experiments.

In addition, the application of tungsten sheets in the field of nuclear fusion research is becoming increasingly important. As the first wall and target material, pure tungsten sheets need to withstand high temperatures, high-energy particle bombardment and thermal cycling while maintaining stable microstructure and mechanical properties. Tungsten’s excellent thermal stability and radiation resistance make it an irreplaceable key material in nuclear fusion reactors.

Precision electronics and high-end manufacturing support materials

The high melting point and low coefficient of thermal expansion of pure tungsten wafers give them unique advantages in precision electronic devices and high-end manufacturing. Tungsten sheets are widely used in microelectronics, semiconductors, vacuum electronics, X-ray tubes, and high-power light sources as targets and heat dissipation materials. Its high thermal conductivity ensures that electronic components can quickly dissipate heat during high-power operation, while its structural stability avoids dimensional drift and electrical degradation caused by thermal expansion.

In high-precision machining and vacuum technology, pure tungsten sheets are often used to manufacture high-vacuum electrodes, precision evaporation sources, and micro-mechanical components, and their excellent high-temperature resistance characteristics and stable chemical properties ensure the long-term stable operation and manufacturing accuracy of equipment

Special machinery and wear-resistant component materials

Tungsten sheets have high hardness and strong wear resistance, making them an important material for key wear-resistant components in the modern machinery industry. For example, high-speed cutting tools, mold liners, and high-load rolling elements can all obtain excellent wear resistance through the processing of tungsten sheets. Tungsten sheets maintain stable mechanical properties under high or high pressure conditions, extending the lifespan of critical mechanical components.

In addition, the application of tungsten sheets in metallurgical rolling, chemical machining, and precision stamping dies has significantly improved the reliability and processing accuracy of production equipment, providing a solid material foundation for industrial manufacturing processes.

Key materials in emerging high-tech and frontier fields

With the development of emerging high-tech fields, the application of pure tungsten sheets has been expanded to the fields of aerospace new materials, nuclear fusion experiments, microelectronic devices, optoelectronic devices and new energy. Tungsten’s high melting point, high density, and stable chemical properties make it ideal for the fabrication of laser targets, electron beam evaporation materials, X-ray targets, and high-power electrodes.

In the field of new energy and functional materials, tungsten wafers are used in energy storage devices and high-temperature catalytic carriers, and their high-temperature stability and thermal conductivity provide reliable support for new energy devices. In the future, with the continuous development of aerospace, nuclear energy, microelectronics and new energy technologies, the strategic position of pure tungsten sheets will become more and more important.

Comprehensive value to modern industry

The importance of pure tungsten sheets lies not only in their physical and chemical properties, but also in their supporting role in modern industrial technology upgrading and high-end manufacturing. It is the basic support for high-temperature materials, nuclear energy materials, electronic devices, precision machinery and cutting-edge technologies, and its stability, reliability and high performance characteristics enable modern industry to operate safely and efficiently in extreme environments.

The application of pure tungsten sheets reflects the close integration of industrial materials and technological development, and its value runs through the entire high-end manufacturing chain. From ensuring energy security and improving equipment reliability to supporting cutting-edge scientific research and emerging industries, pure tungsten sheets are undoubtedly an indispensable strategic material for modern industry.

READ MORE: Encyclopedia of Pure Tungsten Sheet

===================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595