Table of Contents

Chapter 1 Understanding High Density Tungsten Alloy Shielding

1.1 Definition of Heavy Tungsten Alloy Shielding

1.1.1 Material Composition

1.1.2 Structural Characteristics

1.1.3 Functional Positioning of Shielding Components

1.1.4 Typical Product Forms (Sheets, Blocks, Special-Shaped Parts, Etc.)

1.2 Development History of Heavy Tungsten Alloy Shielding

1.2.1 Early Exploration Stage (Emergency of Material Substitution Demand)

1.2.2 Technological Breakthrough Stage (Maturity of Powder Metallurgy Process)

1.2.3 Application Expansion Stage (Penetration from Nuclear Industry to Medical and Other Fields)

1.2.4 Standardization Stage (Establishment of Performance Indicators and Testing Specifications)

Chapter 2 Characteristics of Heavy Tungsten Alloy

2.1 Physical Properties of Tungsten Alloy Shielding

2.1.1 High-Density Characteristics

2.1.1.1 Relationship Between Density and Atomic Number

2.1.1.2 Calculation Relationship Between Material Radiation Protection Ability and Density

2.1.2 Thermal Properties

2.1.2.1 Thermal Conductivity and Heat Dissipation Performance

2.1.2.2 Thermal Stability at High Temperatures

2.2 Mechanical Properties of Tungsten Alloy Shielding

2.2.1 Strength Index

2.2.1.1 Tensile Strength

2.2.1.2 Compressive Strength

2.2.1.3 Impact Resistance Performance

2.2.2 Hardness Characteristics

2.2.2.1 Hardness Test Method

2.2.2.2 Relationship Between Hardness and Wear Resistance

2.3 Chemical Stability Characteristics of Tungsten Alloy Shielding

2.3.1 Corrosion Resistance

2.3.1.1 Acid and Alkali Corrosion Resistance

2.3.1.2 Atmospheric Corrosion Resistance

2.3.2 Antioxidant Properties

2.3.2.1 Oxidation Rate at Room Temperature

2.3.2.2 Antioxidant Performance Under High Temperature Environment

2.4 Processing and Adaptability Characteristics of Tungsten Alloy Shielding

2.4.1 Machinability

2.4.1.1 Feasibility of Cutting, Drilling, and Other Processing

2.4.1.2 Dimensional Control Capabilities of Precision Machining

2.4.2 Complex Compatibility

2.4.2.1 Connection Compatibility With Other Materials

2.4.2.2 Implementation Space of Lightweight Design

2.5 Environmental Performance Characteristics of Tungsten Alloy Shielding

2.5.1 Lead-Free Pollution Characteristics

2.5.2 Recyclability

2.6 Shielding Performance Characteristics of Tungsten Alloy Shielding Parts

2.6.1 High-Efficiency Radiation Attenuation Capability

2.6.1.1 Shielding Adaptability to Different Energy Rays

2.6.2 Long-Term Stability

2.6.2.1 Performance Decay Rate

2.6.2.2 Impact of Environmental Factors on Shielding Effectiveness

2.7 CTIA GROUP LTD Tungsten Alloy Shielding Parts MSDS

Chapter 3 Classification of Heavy Tungsten Alloy Shielding Parts

3.1 Tungsten Alloy Shielding Parts by Material Composition

3.1.1 Tungsten-Nickel-Iron Shielding Components

3.1.1.1 Characteristics of Ingredient Ratio

3.1.1.2 Applicable Scenarios

3.1.2 Tungsten-Nickel-Copper Shielding Components

3.1.2.1 Characteristics of Ingredient Ratio

3.1.2.2 Applicable Scenarios

3.1.3 Other Composite Shielding Components

3.1.3.1 Purpose of Ingredient Design

3.1.3.2 Special Performance

3.2 Tungsten Alloy Shielding Parts by Structural Form

3.2.1 Sheet Metal Shielding

3.2.1.1 Standard Sizes and Customized Specifications

3.2.1.2 Installation and Splicing Methods

3.2.2 Block Shielding

3.2.2.1 Differences Between Solid Blocks and Hollow Blocks

3.2.2.2 Weight and Space Adaptability

3.2.3 Special-Shaped Shielding Parts

3.2.3.1 Design Logic of Complex Structures

3.2.3.2 Processing Difficulties

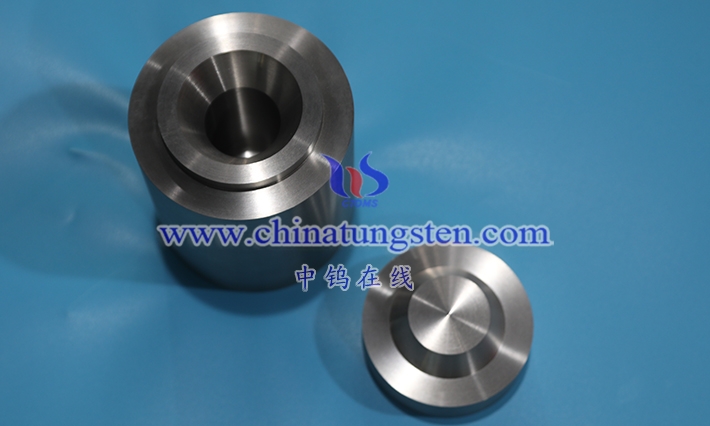

3.2.4 Tungsten Alloy Shielding Can

3.3 Classification of Tungsten Alloy Shielding Parts by Application Scenario

3.3.1 Medical Radiation Protection Shielding Components

3.3.1.1 Built-In Shielding Components of the Device

3.3.1.2 Environmental Protection Shield

3.3.2 Shielding Components for the Nuclear Industry

3.3.2.1 Reactor Peripheral Shielding

3.3.2.2 Nuclear Waste Storage and Transportation Shielding Components

3.3.3 Shielding Components for Industrial Testing

3.3.3.1 Shielding Cover for Flaw Detection Equipment

3.3.3.2 Radiation Source Container

Chapter 4 Shielding Nature of Heavy Tungsten Alloy

4.1 Relationship Between Tungsten Alloy Material Properties and Shielding Capability

4.1.1 Shielding Effect of High Density

4.1.2 Shielding Significance of High Atomic Number

4.2 Basic Principles of Radiation Shielding of Tungsten Alloy Shielding

4.2.1 Photoelectric Effect and Shielding

4.2.2 Compton Scattering and Shielding

4.2.3 Electron Pair Effect and Shielding

4.3 Effect of Tungsten Alloy Composition on Shielding Performance

4.3.1 Effect of Tungsten Content

4.3.2 Effect of Binder Type

4.3.3 Effect of Binder Ratio

Chapter 5 Manufacturing Technology of Heavy Tungsten Alloy Shielding

5.1 Preparation of Tungsten Alloy Shielding Parts by Powder Metallurgy

5.1.1 Tungsten Powder Preparation

5.1.2 Ingredients and Mixed Powder

5.1.3 Pressing

5.1.4 Sintering Treatment

5.2 Precision Machining Technology

5.2.1 Cutting

5.2.2 Grinding

5.2.3 Surface Treatment

5.3 Process Difficulties and Solutions

5.3.1 Difficulties and Countermeasures in Improving Density

5.3.2 Difficulties and Countermeasures in Dimensional Accuracy Control

Chapter 6 Design and Quality Control of High Density Tungsten Alloy Shielding

6.1 Key Points in the Design of Tungsten Alloy Shielding

6.1.1 Design Based on Radiation Type

6.1.2 Design Based on Dose Requirements

6.1.3 Design Based on Space Constraints

6.2 Key Testing Indicators and Methods for Tungsten Alloy Shielding

6.2.1 Density Detection

6.2.2 Shielding Efficiency Test

6.2.3 Mechanical Properties Testing

6.3 Relevant Standards and Compliance Requirements

6.3.1 Chinese Standards

6.3.2 International Standards

6.3.3 Tungsten-Copper Electrode Standards in Europe, America, Japan, South Korea, and Other Countries

Chapter 7 Application Fields of High Density Tungsten Alloy Shielding Parts

7.1 Tungsten Alloy Shielding in Medical Radiation Protection

7.1.1 Application in Radiotherapy Equipment

7.1.2 Protection Applications in CT Machines

7.1.3 Application in Nuclear Medicine Containers

7.1.4 Protection of Interventional Radiotherapy Equipment

7.1.5 Mobile Medical Radiation Protection Screens

7.1.6 Radiopharmaceutical Packaging and Injection Protective Equipment

7.2 Tungsten Alloy Shielding in the Nuclear Industry

7.2.1 Reactor Shielding

7.2.2 Shielding of Long-Term Nuclear Waste Storage Containers

7.2.3 Nuclear Waste Transport Tank Protection Components

7.2.4 Radiation Shielding Devices in Nuclear Power Plant Main Control Rooms

7.2.5 Protective Enclosures for Nuclear Fuel Processing Equipment

7.3 Tungsten Alloy Shielding in Industry and Scientific Research

7.3.1 Nondestructive Testing and Protection Applications

7.3.2 Particle Accelerator Beam Duct Shielding

7.3.3 Shielding of Radioisotope Production Equipment

7.3.4 Laboratory Radiation Source Storage Containers

7.4 Tungsten Alloy Shielding in Geological Exploration

7.4.1 Protective Housing for Radiation Instruments Used in Geological Exploration

7.4.2 Shielding Covers for Mine Radioactive Detection Equipment

7.4.3 Protective Components of Field Radiation Sampling Equipment

Chapter 8 Differences Between High Density Tungsten Alloy Shielding and Traditional Shielding Materials

8.1 Comparison Between Tungsten Alloy Shielding and Lead Shielding

8.1.1 Differences in Environmental Performance

8.1.1.1 Toxicity Comparison

8.1.1.2 Differences in Waste Treatment Costs

8.1.2 Differences in Mechanical Properties

8.1.2.1 Hardness Comparison

8.1.2.2 Impact Resistance Comparison

8.1.2.3 Differences in Performance Stability During Processing

8.2 Comparison Between Tungsten Alloy Shielding and Concrete Shielding Materials

8.2.1 Differences Between Density and Volumetric Efficiency

8.2.1.1 Comparison of Shielding Capabilities Per Unit Volume

8.2.1.2 Differences in Space Occupancy During Device Integration

8.2.2 Differences in Adaptability to Complex Structures

8.2.2.1 Comparison of Processing Capabilities for Special-Shaped Structures

8.2.2.2 Differences in Fit With Precision Equipment

Appendix:

Glossary of Heavy Tungsten Alloy Shielding Terms

References

Chapter 1 Understanding High Density Tungsten Alloy Shielding

1.1 Definition of Heavy Tungsten Alloy Shielding

High-density tungsten alloy shielding is a protective element made from tungsten alloy, attracting widespread attention due to its exceptional density and radiation absorption capabilities. This definition encompasses the material’s application characteristics in specific environments, particularly those requiring shielding from harmful radiation or providing structural support. Produced through advanced metallurgical processes, high-density tungsten alloy shielding combines the high density of tungsten with the synergistic effects of other metal elements to form a composite material with both strength and protective properties. Designed to meet the safety and efficiency requirements of industry and scientific research, it is widely used in applications requiring precise protection. Its unique physical properties have made it an indispensable component in the development of modern technology. With future process improvements and growing application demands, its definition and scope of application are expected to expand further.

high-density tungsten alloy shielding components relies on advances in materials science. The manufacturing process emphasizes raw material selection and process optimization to ensure stable and consistent performance. Products require customized designs tailored to specific application scenarios, demonstrating the material’s versatility and adaptability. Industry-wide technical exchange and R&D investment have driven the continuous refinement of this definition, giving it a significant position in the global market. Future research directions may include more environmentally friendly preparation methods and the exploration of broader applications, injecting new vitality into the development of high-density tungsten alloy shielding components.

1.1.1 Material composition

Material composition is a core component of high-density tungsten alloy shielding, determining its unique advantages in protection and mechanical properties. This material primarily uses tungsten as the matrix element, selected for its extremely high density and excellent radiation absorption capabilities. Tungsten is combined with other metal elements such as nickel, iron, or copper through a specific alloying process to form a high-density composite material. This combination not only retains the excellent properties of tungsten, but also enhances the material’s processing performance and durability through the synergistic effect of the added elements. During the preparation process, the selection and proportion of raw materials are crucial, requiring precise powder metallurgy technology to achieve uniform mixing.

The alloying process usually involves multiple steps such as powder mixing, pressing and sintering, aiming to ensure that the microstructure of the material is dense and free of obvious defects. The role of adding elements is to optimize the ductility and corrosion resistance of the material so that it can adapt to different use environments. Hot isostatic pressing is often introduced to further enhance the uniformity and strength of the material. The optimization of material composition needs to be adjusted in combination with application requirements. For example, in scenarios requiring higher density, the tungsten content may be appropriately increased. Future research may explore the application of new alloying elements or nanotechnology to further improve the performance of the material and meet more stringent industrial standards and usage conditions.

1.1.2 Structural characteristics

Structural characteristics are the basis of the performance of high-density tungsten alloy shielding components, which are reflected in the unique design of their internal organization and external morphology. The microstructure of this material usually shows a uniform grain distribution and a dense phase structure, which is achieved through powder metallurgy or vacuum infiltration. Tungsten provides high-density support as a skeleton structure, while the added metal elements fill in the gap to form a stable composite system. The hot isostatic pressing process plays a key role in structural optimization, reducing porosity and defects and improving the overall density of the material. On a macro scale, shielding components can be designed into a variety of geometric shapes, such as plates, bars or complex curves, to meet different installation and usage requirements.

External structural features also include surface smoothness and machining accuracy. Post-processing processes such as cutting and grinding are often used to refine the surface and ensure seamless integration with equipment. The uniformity of phase distribution within the microstructure directly impacts the material’s radiation absorption capacity and mechanical strength, necessitating strict control of process parameters during fabrication. Structural stability is particularly important in high-temperature or high-stress environments, and heat treatment can further enhance its resistance to deformation.

READ MORE:What Is High Density Tungsten Alloy Shielding

===================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595