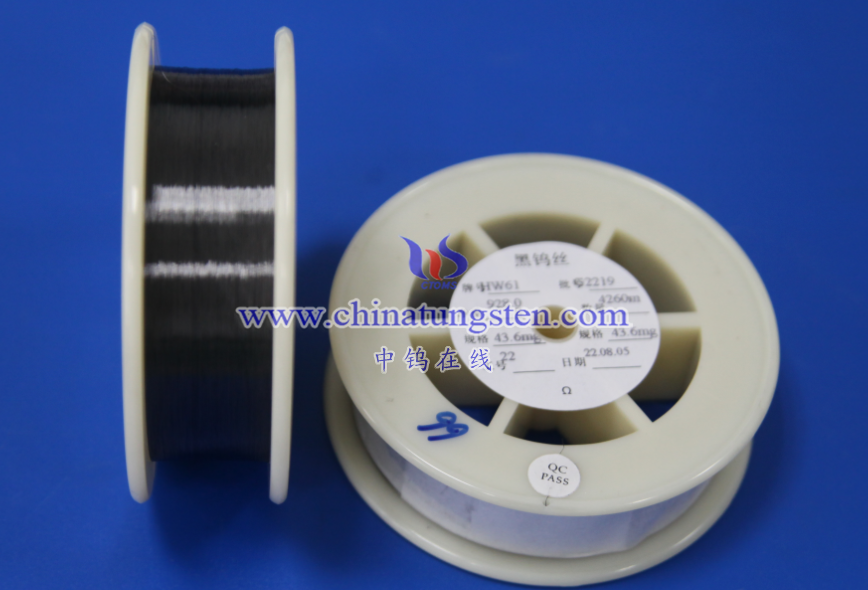

Black tungsten wire exhibits excellent mechanical properties at high temperatures, including high strength, creep resistance, high elastic modulus, and good thermal fatigue resistance. However, risks such as high-temperature oxidation, volatilization, and brittleness must be managed through material design and process optimization.

- High-Temperature Strength and Creep Resistance

- High Strength: Tungsten has a melting point of 3410°C, the highest among all metals. At elevated temperatures (e.g., above 1000°C), tungsten wire retains high tensile and yield strength, far surpassing many other metals (e.g., iron, copper).

- Creep Resistance: Creep is the slow deformation of a material under constant stress at high temperatures. Tungsten wire demonstrates excellent creep resistance due to its high melting point, strong covalent bonds, and low diffusion coefficient. This ensures minimal permanent deformation during prolonged high-temperature use, making it suitable for applications requiring long-term stability (e.g., light bulb filaments, heating elements).

- High-Temperature Elasticity and Rigidity

- Elastic Modulus: Tungsten’s elastic modulus (approximately 411 GPa) decreases slowly at high temperatures, indicating its ability to maintain rigidity and resist elastic deformation.

- Rigidity Retention: Compared to other metals, tungsten wire resists softening at high temperatures, maintaining structural stability. This makes it ideal for applications requiring precise shape control (e.g., electron microscope filaments, vacuum electron devices).

- High-Temperature Fatigue Performance

- Thermal Fatigue Resistance: Tungsten wire may develop fatigue cracks due to thermal stress from repeated heating and cooling cycles. However, its high thermal conductivity (approximately 173 W/(m·K)) helps distribute temperature evenly, reducing localized thermal stress and delaying crack propagation.

- Cycle Life: With proper design (e.g., controlling heating/cooling rates, avoiding extreme temperature fluctuations), tungsten wire can withstand thousands of high-temperature cycles without failure, suitable for intermittent high-temperature equipment.

- High-Temperature Oxidation Resistance and Surface Stability

- Oxide Layer Formation: Black tungsten wire typically has a surface layer of tungsten oxide (e.g., WO₃), which slows further oxidation at high temperatures, protecting the underlying metal. However, the oxide layer may thicken with increasing temperature, leading to surface embrittlement or spalling.

- Volatilization Loss: At extremely high temperatures (e.g., above 2000°C) or in vacuum environments, tungsten may lose mass due to volatilization, affecting mechanical properties. In practical applications, coatings (e.g., rhenium, iridium) or inert gas protection are used to suppress volatilization.

- Plastic Deformation and Processability

- High-Temperature Plasticity: Tungsten retains low plasticity at high temperatures, making cold working difficult. Hot working (e.g., wire drawing, forging) is typically required at temperatures above 1500°C, followed by rapid cooling to prevent grain coarsening.

- Brittleness Risk: At high temperatures, tungsten wire may become brittle due to grain boundary weakening or impurity segregation. Purification (e.g., zone melting) and grain refinement (e.g., adding rare earth elements) can mitigate this.

- Performance in Practical Applications

- Light Bulb Filaments: In incandescent lamps, tungsten wire operates at temperatures above 2500°C. Its high strength and creep resistance ensure the filament remains intact during prolonged use.

- Heating Elements: In high-temperature furnaces and thermocouples, the stable mechanical properties of tungsten wire make it an ideal material.

- Electronic Devices: In electron microscopes and X-ray tubes, tungsten wire must maintain precise shapes at high temperatures, where its high elastic modulus and creep resistance are critical.

More details of tungsten wire, please visit website: http://www.tungsten-wire.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten wire:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595