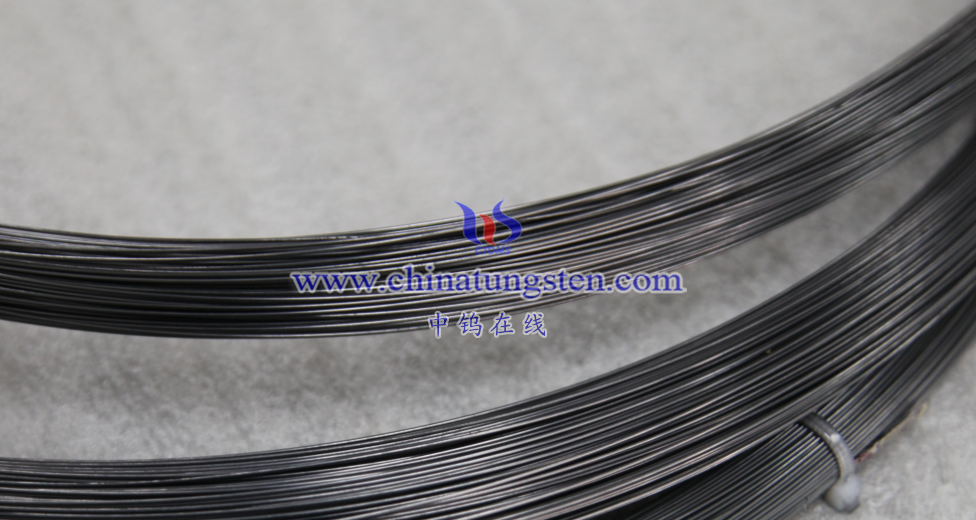

The surface roughness of black tungsten wire significantly impacts its mechanical strength, electrical properties, thermal performance, and chemical stability. The specific effects depend on the application environment and requirements, and a trade-off must be considered to determine whether additional surface treatments (e.g., polishing or coating) are necessary to optimize performance.

Mechanical Properties:

- Black tungsten wire with high surface roughness may have micro-cracks or defects, which act as stress concentration points, making the wire more prone to fracture under tension or bending, thus reducing mechanical strength and toughness.

- A rough surface may increase the friction coefficient, leading to increased wear in applications involving sliding or contact.

Electrical Properties:

- In electrical heating applications (e.g., filaments or heating elements), surface roughness can affect current distribution. A rough surface may cause uneven local current density, increasing the risk of localized overheating and shortening service life.

- Rough surfaces may increase contact resistance, particularly in applications requiring connections with electrodes or other components, affecting electrical performance.

Thermal Properties:

- A rough surface increases surface area, potentially enhancing heat radiation efficiency, which can be beneficial in certain high-temperature applications (e.g., filaments). However, it may also lead to uneven heat dissipation, affecting thermal stability.

- Surface defects may cause localized high-temperature spots, accelerating material aging or burnout.

Chemical Stability and Corrosion Resistance:

- Rough surfaces are more likely to adsorb gases or impurities, especially in high-temperature or vacuum environments, potentially triggering oxidation or other chemical reactions that reduce the wire’s corrosion resistance and lifespan.

- High surface roughness may make tungsten wire more susceptible to corrosion in certain chemical environments.

Processing and Application Adaptability:

- In applications requiring precision machining or high consistency (e.g., electronic devices, vacuum tubes), the high surface roughness of black tungsten wire may not meet requirements, necessitating further polishing or treatment.

- Rough surfaces may affect the adhesion or weldability of tungsten wire with other materials.

Practical Impact Varies by Application:

- In some applications (e.g., certain types of filaments), the rough surface of black tungsten wire may be intentionally retained to enhance specific properties (e.g., heat radiation).

- However, in high-precision or high-reliability scenarios (e.g., aerospace or semiconductor manufacturing), polishing or surface treatments are often required to reduce roughness, improving performance and lifespan.

More details of tungsten wire, please visit website: http://www.tungsten-wire.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten wire:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595