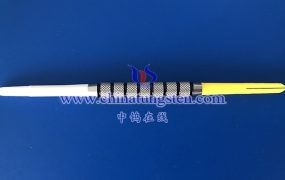

A tungsten alloy dart barrel, precision-machined from high-specific-gravity tungsten alloy, possesses seven mutually coupled basic features. First, extremely high density allows minimal volume for the same mass, with barrel diameter slim enough for complete fingertip wrapping, supporting compact grouping throws. Second, superior hardness ensures lifelong sharpness of surface knurling, ring cuts, and spiral grooves, with constant fingertip granular sensation. Third, outstanding rigidity ensures no macroscopic deformation at release, converting 100% of wrist kinetic energy into dart translation and rotation. Fourth, low thermal expansion coefficient guarantees zero dimensional drift from competition lighting high temperature to outdoor low temperature, with environment-independent hand feel. Fifth, chemical inertness synergized with functional coatings achieves full-scenario corrosion resistance against sweat, beverages, and salt spray, preserving original surface color. Sixth, high machinability supports complex geometry in one forming, combined with laser etching to achieve personalized grip zone textures. Seventh, full-lifecycle recyclability allows 100% reuse of tungsten and binder phases after barrel refurnacing, meeting zero-waste competition requirements. These basic features are realized through powder metallurgy microscopic optimization and CNC macroscopic precision machining, forming a closed-loop engineering chain “from powder to fingertips,” ensuring each barrel maintains factory-level center of gravity accuracy and tactile signature after millions of throw cycles, defining the “lifelong consistency” standard for modern dart barrels, with systematic integration of basic features making the tungsten alloy dart barrel the absolute benchmark for competitive performance.