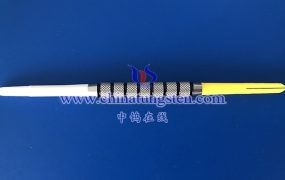

A tungsten alloy dart barrel is precision-machined from high-specific-gravity tungsten alloy, which uses tungsten powder as the primary mass source, supplemented by nickel, iron, or copper as binder phases, achieving metallurgical bonding through liquid-phase sintering. Tungsten powder is selected as high-purity near-spherical particles to ensure a continuous three-dimensional skeleton after forming, providing the foundation for density and rigidity; the binder phase wets tungsten particles in high-temperature liquid state, filling gaps and forming transition layers, endowing the alloy with toughness and impact resistance. The nickel-iron system enhances hardness and magnetic responsiveness, suitable for front-weighted competition barrels; the nickel-copper system strengthens corrosion resistance and thermal conductivity, suitable for rear-weighted control barrels. After sintering, the blank undergoes vacuum heat treatment to eliminate residual stress, with the surface receiving five-axis CNC precision turning and functional coating. Coatings include diamond-like carbon, titanium nitride, or composite films, customized according to the player’s hand sweat pH and friction preference. The entire barrel is fully traceable via spectroscopy from raw material to finished product, ensuring consistent tungsten content gradient, binder phase ratio, and center of gravity position within batches. Auxiliary materials include trace lubricants (volatilized during sintering) and temporary masks (for surface zoning), with the final product containing no harmful elements and supporting full-element recycling. This material composition makes the tungsten alloy dart barrel “programmable metallic muscle,” achieving precise mapping of macroscopic performance at the microscopic scale, with material composition optimization directly determining barrel performance consistency after millions of throws.