Swaging and drawing are key steps in tungsten wire processing. The specific process is as follows:

Swaging: The sintered tungsten blank (tungsten rod) is heated to approximately 1400–1600°C (high temperature imparts some plasticity to tungsten). A rotary swaging machine is used to repeatedly hammer the tungsten rod, gradually reducing its diameter and increasing its length. During swaging, temperature and deformation must be controlled to prevent crack formation while improving the crystal structure of tungsten.

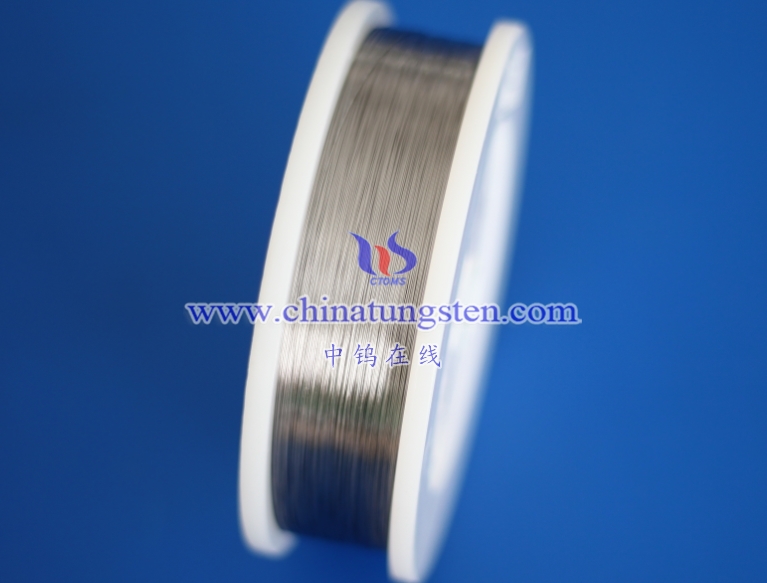

Wire Drawing: The swaged tungsten rod is further annealed for softening and then cold-drawn or hot-drawn through wire drawing dies (typically diamond or carbide dies). The drawing process is performed in multiple passes, with each pass reducing the diameter by about 10–20%. Intermediate annealing (at approximately 1000–1200°C) is required multiple times to relieve work hardening. Drawing continues until the final diameter (ranging from a few microns to several millimeters) is achieved, ensuring surface smoothness and dimensional accuracy.

Swaging and drawing must be conducted under precisely controlled temperature and environmental conditions to prevent brittle fracture of tungsten.

More details of tungsten wire, please visit website: http://www.tungsten-wire.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten wire:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595