The production of cleaned tungsten wire requires the following key equipment:

- Reduction Furnace: Used to reduce tungsten trioxide to tungsten powder (e.g., hydrogen reduction furnace).

- Powder Mixer: For uniform mixing of dopants with tungsten powder.

- Hydraulic Press: For pressing tungsten powder into blanks.

- Sintering Furnace: For high-temperature sintering of tungsten blanks (under vacuum or hydrogen protection).

- Rotary Swaging Machine: Equipped with swaging dies for rotary swaging of tungsten rods.

- Wire Drawing Machine: Equipped with high-precision drawing dies for drawing tungsten wire.

- Annealing Furnace: For intermediate and final annealing treatments.

- Graphite Emulsion System: To reduce friction and prevent oxidation.

- Electrolytic Polishing Equipment: For surface cleaning and polishing.

- Inspection Equipment: Such as microscopes, tensile testing machines, and surface roughness testers for quality control.

- Vacuum or Inert Gas Protection Equipment: To ensure an oxygen-free environment during high-temperature processing.

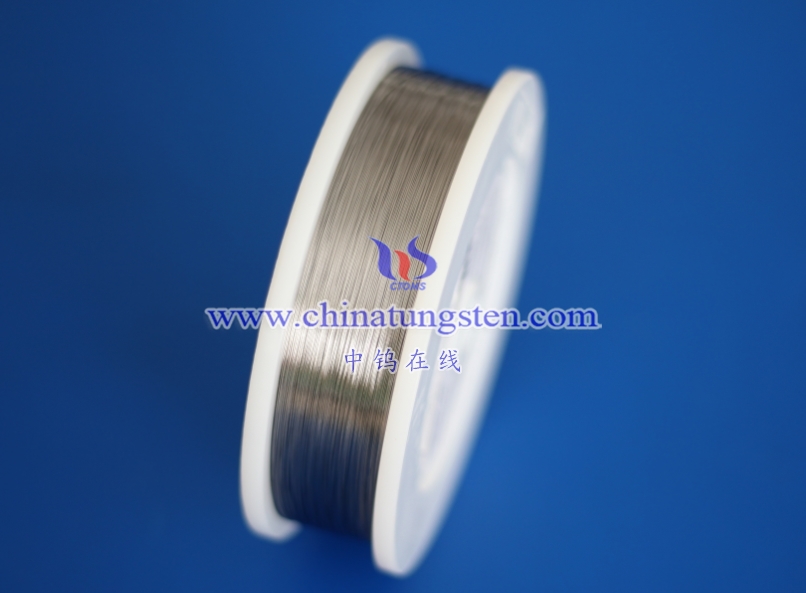

More details of tungsten wire, please visit website: http://www.tungsten-wire.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten wire:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595