The production of cleaned tungsten wire involves high energy consumption, primarily due to the following energy-intensive steps:

- Reduction and Sintering: Reducing WO₃ and sintering tungsten blanks require high temperatures (800–3000°C), consuming a large amount of electricity and accounting for approximately 50–60% of total energy use.

- Swaging and Drawing: Continuous energy supply is needed for heating and mechanical processing, especially during multiple annealing processes.

- Heat Treatment and Polishing: Annealing furnaces and electrolytic polishing equipment also contribute to energy consumption.

Specific energy consumption varies depending on process and equipment efficiency. Modern factories reduce energy use by optimizing equipment (e.g., high-efficiency electric furnaces) and recovering waste heat. On average, producing one ton of tungsten wire may consume several thousand to tens of thousands of kilowatt-hours of electricity, though exact figures depend on factory scale and process specifics.

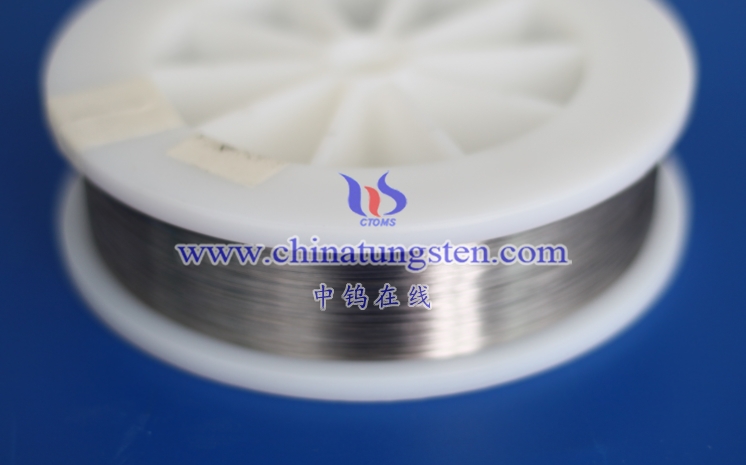

More details of tungsten wire, please visit website: http://www.tungsten-wire.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten wire:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595