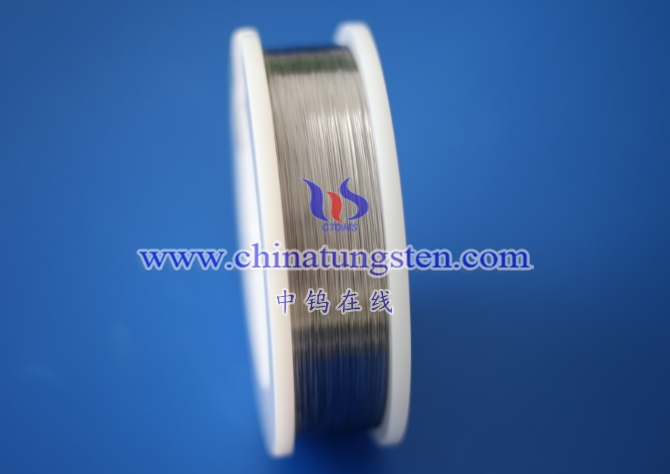

Cleaned tungsten wire is primarily used in high-speed machining of alloy steel as a reinforcement material for cutting tools or as electrode wire in electrical discharge machining (EDM). Its specific roles include:

- Cutting Tool Reinforcement: The high hardness and wear resistance of cleaned tungsten wire make it an ideal substrate or coating material for cutting tools, enhancing durability for high-speed machining of high-hardness alloy steels (such as tool steel or stainless steel). Its resistance to high-temperature softening ensures the tool remains sharp under intense friction.

- EDM Electrode: Due to its high melting point, good electrical conductivity, and low thermal expansion coefficient, cleaned tungsten wire is used as electrode wire in EDM to precisely cut complex-shaped alloy steel components. Its resistance to arc erosion ensures high precision and surface finish during processing, making it particularly suitable for high-precision parts in aerospace or mold manufacturing.

- Thermal Stability and Longevity: Cleaned tungsten wire resists deformation and wear in the high-temperature environments generated during high-speed cutting or EDM, significantly extending the service life of tools or electrodes and reducing production costs.

More details of tungsten wire, please visit website: http://www.tungsten-wire.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten wire:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595