Glass melting molybdenum electrode is a special electrode material used in the glass industry. It is mainly used for resistance heating in the process of glass melting to provide melting temperature and heat source for molten glass. Glass smelting molybdenum electrodes are usually made from high purity molybdenum material, which has excellent high temperature performance and corrosion resistance.

During the glass melting process, molybdenum electrodes are installed in the furnace and heated by electric current to provide thermal energy. The molybdenum electrode has good electrical conductivity and high temperature resistance, can withstand the electrothermal effect in a high temperature environment, and transfer heat energy to the glass melting pool. It has excellent thermal conductivity, can transfer heat quickly and keep the temperature stable, ensuring the controllability and efficiency of the melting process.

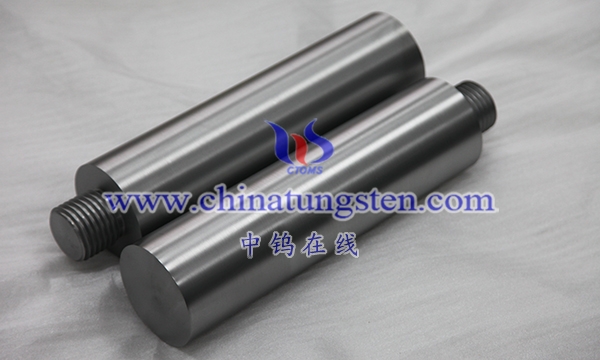

Molybdenum electrodes for glass melting usually come in certain shapes and sizes to suit different types and sizes of glass melting furnaces. They can be cylindrical, rod or plate, depending on the design and requirements of the furnace.

Molybdenum electrodes for glass melting have a wide range of applications in the glass industry, especially in large glass melting furnaces and special glass production. They can provide a stable heat source to ensure uniform heating of the glass melting pool and control of the melting process, resulting in high-quality glass products.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595