Molybdenum rods can be classified according to different manufacturing processes, shapes and application fields. The following are several common molybdenum rod types

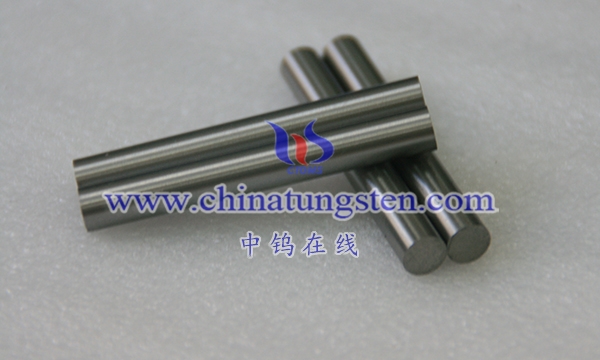

Solid Molybdenum Rod: Solid Molybdenum Rod is the most common type of molybdenum rod, which is made of pure molybdenum material and has a cylindrical shape. Solid molybdenum rods are widely used in high temperature furnaces, vacuum furnaces, medical equipment and electronic devices and other fields.

Fiber molybdenum rod (Molybdenum Wire Rod): Fiber molybdenum rod is a rod-shaped material twisted by multiple molybdenum wires. Fibrous molybdenum rods are commonly used in applications such as electrodes, emitters, vacuum tubes, and electronic packaging, which have excellent electrothermal properties and mechanical strength.

Alloy Molybdenum Rod: Alloy Molybdenum Rod is a molybdenum rod manufactured by alloying molybdenum with other elements (such as niobium, tantalum, zirconium, etc.). Alloyed molybdenum rods can be tailored to specific alloy formulations for special high temperature, corrosion resistance and high strength applications.

Hollow Molybdenum Rod (Hollow Molybdenum Rod): Hollow Molybdenum Rod is a molybdenum rod that is drilled inside a solid molybdenum rod to form a hollow structure. Hollow molybdenum rods are widely used in applications such as heating elements and thermal diffusion shields in vacuum equipment to provide higher heating efficiency and lighter weight.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595