Tungsten is one of the hardest metals, with a high hardness rating on the Mohs scale. The hardness of tungsten needles is similar to other materials that are commonly used for needles, such as stainless steel and titanium. However, tungsten is harder than many other metals and alloys, including brass, aluminum, and copper.

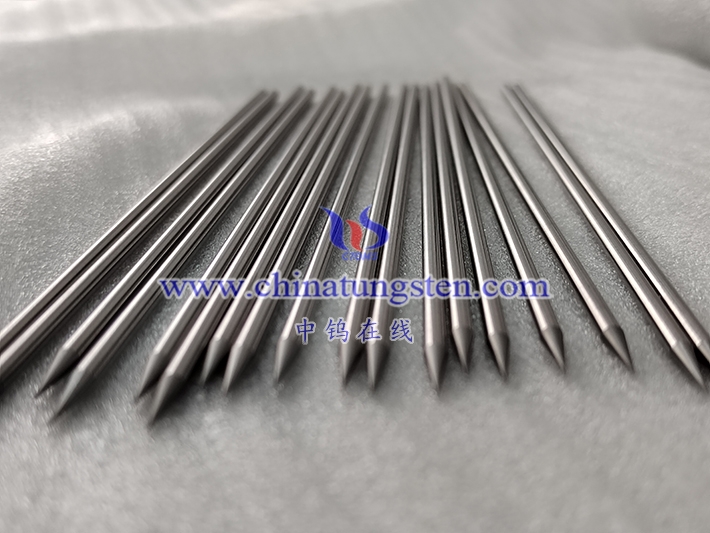

The high hardness of tungsten makes it an ideal material for applications where the needle needs to withstand high stresses and wear, such as in precision machining, scientific research, and medical procedures. Tungsten needles are also less likely to deform or bend under pressure than other materials, making them more durable and long-lasting.

In addition to its high hardness, tungsten is also very dense, which further improves its strength and wear resistance. The combination of high hardness and density makes tungsten needles a popular choice for demanding applications that require high precision and durability.