Nano-cesium tungsten bronze CsxWO3 not only has strong absorption characteristics in the near infrared region (wavelength of 800-1100nm), but also has strong transmission characteristics in the visible light region (wavelength of 380-780nm), and has strong transmission characteristics in the ultraviolet region (wavelength of 200nm). -380nm) also has strong shielding properties. The most common product of nano-cesium tungsten bronze is nano-cesium tungsten bronze-coated glass. The following steps are usually required to prepare nano-cesium tungsten bronze-coated glass:

Prepare materials:

Nano cesium tungsten bronze particles: can be purchased or prepared by synthetic methods.

Appropriate amount of solvents: such as organic solvents such as ethanol and acetone.

Glass substrate: the base material for coating nano cesium tungsten bronze coating.

Preparation of nano cesium tungsten bronze solution:

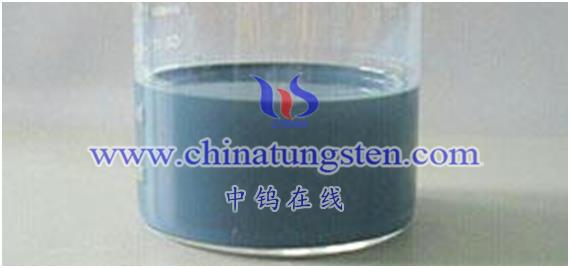

Add nano-cesium tungsten bronze particles into an appropriate amount of solvent, and use methods such as ultrasonic treatment or stirring to make them uniformly dispersed.

Surface treatment:

Clean the glass substrate to remove the dirt and impurities on the surface to ensure that the surface of the substrate is clean.

Coating nano cesium tungsten bronze solution:

The nano cesium tungsten bronze solution is evenly coated on the surface of the glass substrate. Can be applied by brush, spray, etc.

Drying and annealing:

Place the glass substrate coated with the nano cesium tungsten bronze solution at an appropriate temperature for drying and annealing. This helps remove the solvent and allows the nanoparticles to combine into a dense coating.

Characterization and Testing:

Characterize and test the prepared nano-cesium tungsten bronze coating, for example, observe the surface morphology by scanning electron microscope (SEM), analyze the crystal structure by X-ray diffraction (XRD), etc.

Taking the production of subordinate samples in practice as an example, the process is:

After fully grinding and ultrasonically dispersing the CsxWO3 powder, add it to 0.1g/ml polyvinyl alcohol PVA solution, stir in water at 80°C for 40 minutes, and after aging for 2 days, use roller coating method on ordinary glass (7cm*12cm *0.3cm) to form a thin film to obtain CsxWO3 coated glass.

The above steps provide a general method for preparing nano cesium tungsten bronze coated glass, and the specific steps may vary due to the different preparation conditions, materials and equipment used.

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595