Carbide turning insert specifications will vary depending on the specific application and usage requirements. The following are the specifications of some common carbide turning inserts:

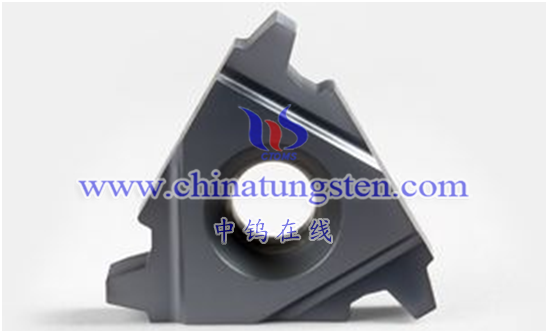

Blade shape: The blade shape of carbide turning inserts can have different designs, such as round, square, triangle, diamond, etc.

Blade size: including blade length, width, thickness and other parameters. Different sizes are suitable for turning workpieces of different sizes.

Number of cutting edges: The number of cutting edges of carbide turning inserts can be single-edge, double-edge or multi-edge designs. Multi-edged inserts can improve cutting efficiency and machining accuracy.

Cutting angle: The cutting angle refers to the angle between the cutting edge surface of the insert and the surface of the workpiece. Common cutting angles include 45 degrees, 60 degrees, 90 degrees, etc.

Blade coating: Carbide turning blades can use different types of coatings, such as titanium carbide (TiC) coating, titanium nitride (TiN) coating, etc., to improve the wear resistance and corrosion resistance of the blade.

In addition, the specifications of cemented carbide turning inserts also include parameters such as the applicable range of cutting materials, cutting depth, and cutting speed. The specific specification selection should be determined according to the material, size and processing requirements of the workpiece to ensure the best cutting effect and processing quality.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595