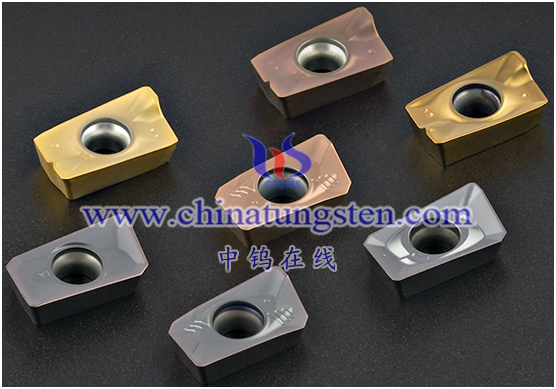

Carbide-coated blades refer to blades with a special coating covering the surface of the carbide blade. This coating is usually composed of high-hardness compound materials, such as nitrides, carbides or oxides. Common coating materials include titanium carbide (TiC), titanium nitride (TiN), aluminum nitride (AlN), silicon nitride (SiN), etc.

Carbide coated inserts offer the following features and benefits:

Wear resistance: The coating can provide the blade with higher hardness and wear resistance, extending the service life of the tool.

Reduce friction coefficient: The coating can reduce the friction between the tool and the workpiece, reduce the generation of cutting force and heat, reduce the cutting temperature, thereby improving the quality of the machined surface.

Anti-Stickness: Coatings reduce the likelihood of chips sticking to the tool, reducing build-up during cutting and the risk of tool breakage.

Corrosion resistance: The coating can provide the blade with better corrosion resistance and is suitable for handling a variety of materials and working environments.

Increased cutting speed: Because the coating reduces friction and heat generation between the tool and the workpiece, carbide-coated inserts can operate at higher cutting speeds, improving production efficiency.

Carbide-coated inserts are widely used in metal processing fields, such as turning, milling, drilling, boring and other processes, and can significantly improve cutting performance and processing quality. Coating type and selection should be determined based on the specific processing materials and processing conditions to obtain the best cutting results and service life.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595