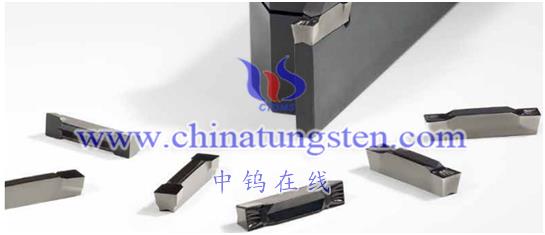

Silicon nitride coated (SiN) carbide inserts are carbide inserts with a silicon nitride film coated on the blade surface. Silicon nitride is a ceramic material with excellent wear resistance, high hardness and high temperature resistance. The main features of silicon nitride coated inserts are as follows:

High Hardness: Silicon nitride has extremely high hardness, which can reach 1800-2200HV, giving the blade excellent wear resistance and cutting performance.

High temperature resistance: Silicon nitride coating can maintain stable performance in high temperature environments, resist high temperature thermal expansion and thermal shock, and is suitable for high temperature cutting.

Low friction coefficient: Silicon nitride coating has a low friction coefficient, which reduces friction and heat accumulation during cutting, reduces cutting force and cutting temperature, and extends tool life.

Good thermal conductivity: Silicon nitride has good thermal conductivity, which can effectively dissipate the heat generated during the cutting process, reduce the increase in tool surface temperature, and improve cutting stability.

Anti-adhesion: The silicon nitride coating has a smooth surface, low surface roughness and chemical inertness, which can prevent welding and adhesion during the cutting process and reduce the friction and wear of the tool.

Silicon nitride coated carbide inserts are commonly used in high-speed cutting, dry cutting, drilling, milling and other applications. They are suitable for processing steel, cast iron, stainless steel, composite materials and other materials, providing higher cutting efficiency, workpiece surface quality and Tool life.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595