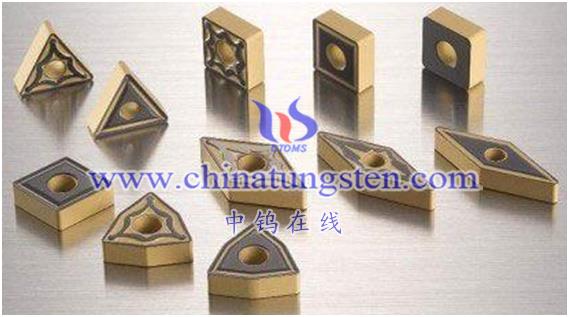

Tantalum-coated (Ta) carbide inserts are carbide inserts with a tantalum film coated on the blade surface. Tantalum is a metal material with high melting point, corrosion resistance and good chemical stability. The main features of tantalum coated inserts are as follows:

Good wear resistance: Tantalum has high hardness and wear resistance, and the coating can provide the blade with better wear resistance and extend the tool life.

Excellent heat resistance: Tantalum coating can maintain stable performance in high temperature environments, has a high melting point and high temperature corrosion resistance.

Anti-adhesion: The tantalum coating has a smooth surface, low surface energy and chemical inertness, which reduces welding and adhesion during the cutting process, and reduces tool friction and wear.

Good chemical stability: Tantalum has good chemical stability and can resist chemical corrosion and oxidation, extending the service life of tools in corrosive environments.

Low friction coefficient: Tantalum coating has a low friction coefficient, which reduces the friction between the tool and the workpiece and improves cutting efficiency.

Tantalum-coated carbide inserts are often used in high-temperature cutting, high-hardness material processing, corrosion-resistant material processing and other fields, such as aerospace, medical equipment, chemical industry and other industries. They have high wear resistance, heat resistance and chemical stability, providing efficient, stable cutting performance and extended tool life.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595