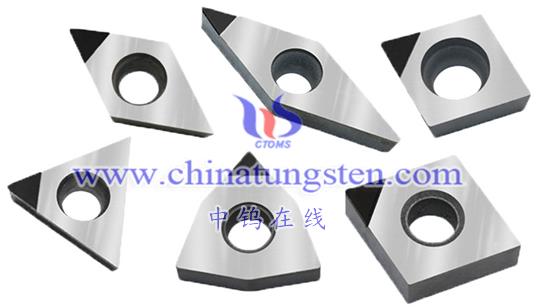

Diamond coated (DLC) carbide inserts are tools that are coated with a diamond-like film on the surface of the carbide insert. DLC coating is an amorphous carbon film composed of carbon elements, which contains carbides with a diamond-like structure. It has the following characteristics:

Extremely high hardness: Diamond is one of the hardest substances currently known, and its hardness is close to that of natural diamond. Diamond coating significantly increases the hardness and wear resistance of the blade.

Excellent wear resistance: Diamond coating has excellent wear resistance, which can keep the cutting edge of the blade sharp under high-speed cutting and heavy cutting conditions and extend the service life of the tool.

Low friction coefficient: Diamond coating has a low friction coefficient, reducing friction and heat accumulation between the tool and the workpiece, improving cutting efficiency.

Good corrosion resistance: Diamond coating has high chemical stability and corrosion resistance, and can resist corrosion from acids, alkalis, chemical solutions and high-temperature environments, extending the service life of the tool.

Excellent surface quality: Diamond coating has a smooth surface, improving the surface quality and processing accuracy of the tool.

Diamond-coated carbide inserts are widely used in high-hardness material processing, non-ferrous metal processing, high-precision processing and other fields, such as aerospace, automobile manufacturing, mold manufacturing and other industries. They offer excellent cutting performance, efficient machining speeds and long tool life, making them a high-performance tool option.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595