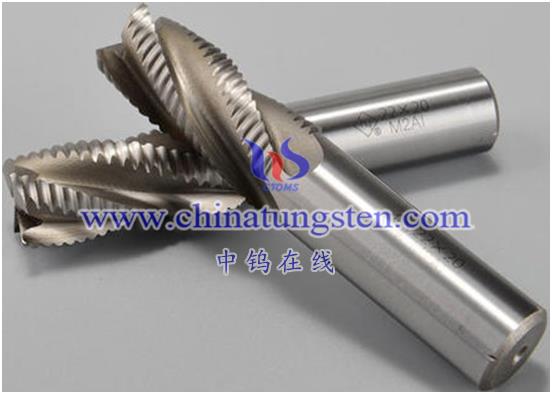

A carbide groove mill is a cutting tool used for groove milling on machine tools. It is mainly used to process grooves, notches, grooves and other shapes on the surface of the workpiece. The cutting tool part of the carbide groove milling cutter is made of carbide material. The common carbide material is a composite material of tungsten carbide (WC) and cobalt (Co). This material has high hardness, wear resistance and high temperature resistance, allowing long tool life during cutting. The insert shape and tool structure of carbide groove milling cutters vary according to different processing requirements. Common types include straight-edge groove milling cutters, spiral groove milling cutters, T-groove milling cutters, V-groove milling cutters, etc. According to the processing requirements and the groove shape of the workpiece, a suitable carbide groove milling cutter can be selected for processing. Carbide groove milling cutters are widely used in the field of metal processing and can be used to mill various metal materials, such as steel, aluminum, copper, cast iron, etc. It is commonly used in mold manufacturing, mechanical parts processing, automobile manufacturing, aerospace and other industries. It can achieve high-precision groove processing and improve production efficiency and processing quality.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595