The Hardmetal Hole Saw Drill Bit is a tool used for drilling and is widely used in hole processing in metal, plastic, wood and other materials.

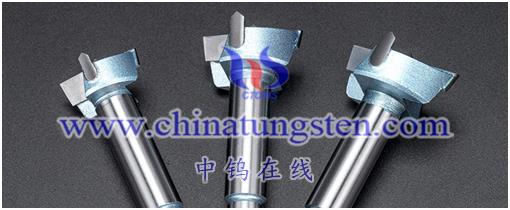

Carbide hole opener drill bits usually consist of cutting teeth, drill bit body and pilot drill pins. Cutting teeth are cutting blades or gear pieces made of carbide, which have high hardness and wear resistance. The drill bit body is the cylindrical part that houses the cutting teeth and provides the cutting force required to machine the hole. The pilot drill pin is located in the center of the drill bit and is used to accurately position and guide the drill bit on the work surface.

Carbide hole opener drill bits have the following features:

Versatility: They are suitable for drilling different materials, including metal, plastic, wood, and more. Different cutting tooth materials and designs can be selected to suit different application requirements.

Efficient machining: Carbide cutting teeth have sharp cutting edges and good wear resistance, enabling smooth and precise holes to be machined quickly and efficiently.

Cutting quality: Carbide hole opener drill bits can usually provide high-precision holes, and their cutting process is relatively smooth and not easy to produce burrs or damage the workpiece surface.

Durability: Due to the high hardness and wear resistance of carbide materials, carbide hole opener drill bits generally have a long service life and maintain good cutting performance over multiple uses.

Carbide hole opener drill bits are widely used in home decoration, machining, electrical installation and other fields. They provide users with efficient, precise and reliable hole machining solutions to meet hole requirements in a variety of applications.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595