There are two main types of coring carbide drill bits:

Scraper core drill bit: This drill bit consists of a carbide block, a scraper blade, the upper and lower bodies of the drill bit, etc. Depending on whether there are water holes, scraper coring bits can be divided into two types: those with water holes and those without water holes.

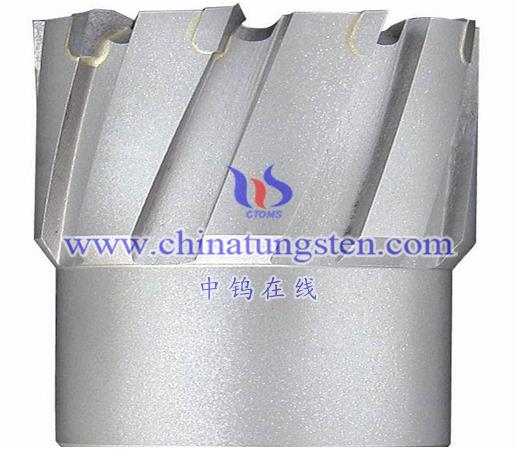

Abrasive core drill bit: This drill bit consists of a carbide column, drill bit crown, and drill bit body. The crown and gauge parts of this drill bit are inlaid with hexagonal or octagonal prism-shaped carbide to improve wear resistance, making it suitable for coring in medium-hard to hard formations.

Coring alloy drill bits can be divided into sharpened drill bits and self-sharpening drill bits according to the properties of the rock being drilled.

Carbide drill bits are inlaid with a sharpening alloy that can be sharpened; as the drill bit drills, the alloy will continue to wear and become dull.

The speed also gradually decreased. Self-sharpening carbide drill bits are inlaid with self-sharpening alloys with small sections (thin slices or cylindrical shapes); this

The alloy is not blunted when the drill bit drills, and the drilling speed remains basically unchanged.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595