Self-sharpening carbide drill bits are inlaid with self-sharpening alloys with small sections (thin slices or cylindrical shapes); the alloy is not blunted when drilling with this drill bit, and the drilling speed is basically unchanged.

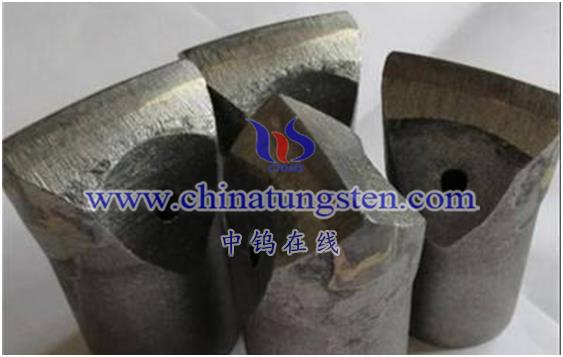

The self-sharpening carbide drill bit is a commonly used coring drill bit, mainly suitable for hard and abrasive rock formations. Its structure is mainly composed of small-section needle-shaped carbide cutting tools and wrapping metal or supporting metal.

During use, as the drill bit is drilled, the wrapping metal or supporting metal is worn away before the cutting tool, so that the small section of the cutting tool is continuously exposed to break the rock formation. Self-sharpening drill bits are suitable for hard and abrasive rock formations with developed fissures and drillability of grades VI to VIII.

Self-sharpening carbide drill bits need to avoid core clogging during use to ensure core quality. At the same time, in order to extend the service life of the drill bit, regular maintenance is required. The self-sharpening carbide drill bit is a coring bit suitable for specific rock formations. It has high footage speed and drilling efficiency, but it needs to pay attention to the characteristics of specific rock formations and core clogging problems, and perform regular maintenance.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595